Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

1300mm tesion leveler aluminum

stock No.: 371, it is written on July 17, 2022- product description

- Technical Parameters

machine is made in 2006, just stopped running in July,2022

machine is complete, no missing parts

1. Input material: pure aluminum and aluminum alloy 1000 series, 3003, 8011

2. Input material performance: 1) tensile strength: σ b≤ 80-350N/mm2

2) Yield strength: σ b≤50-300N/mm2

3. Input coil width: 800-1350mm

4. Input coil thickness: 0.1-1.2mm

5. Input coil OD: max Φ 1700mm

6. Input Coil weight: Q max. 7500kg

7. Sleeve size: Φ 505/565 × 1450(1600)mm

8. Incoming coil shape: ≤ 401

9. Finished product width: 700-1300mm

10. Working speed of the train: 0-100-200m/min

Aluminum strip thickness: ≤ 0.75mm v=0-200m/min

Aluminum strip thickness: > 0.75mm v=0-100m/min

Cleaning speed: v=0-100m/min

11. Line speed: 0-50m/min

12. Maximum elongation: 0-3% stepless continuous adjustable

13. Accuracy of elongation: ± 0.01%

14. Maximum tensile force: 146kn (meet σ ≤ 180n/mm2, specification

15. Speed accuracy: ± 0.1%

16. Tension accuracy: ± 0.5%

17. Inner diameter of finished coil: Φ 505/ Φ 405mm (sleeve inner diameter)

18. Outer diameter of finished roll: max.1700mm

19. Plate type after tension correction: ≤ 51 (incoming plate type ≤ 401)

20. Strip passing elevation: +1100mm

21. Coiling stagger tolerance: ≤± 0.5mm

22. Coiling tower shape tolerance: ≤± 1.0mm

23. Trimming width accuracy: ≤± 0.3mm

24. Train running direction: stand on the operation side and look from left to right

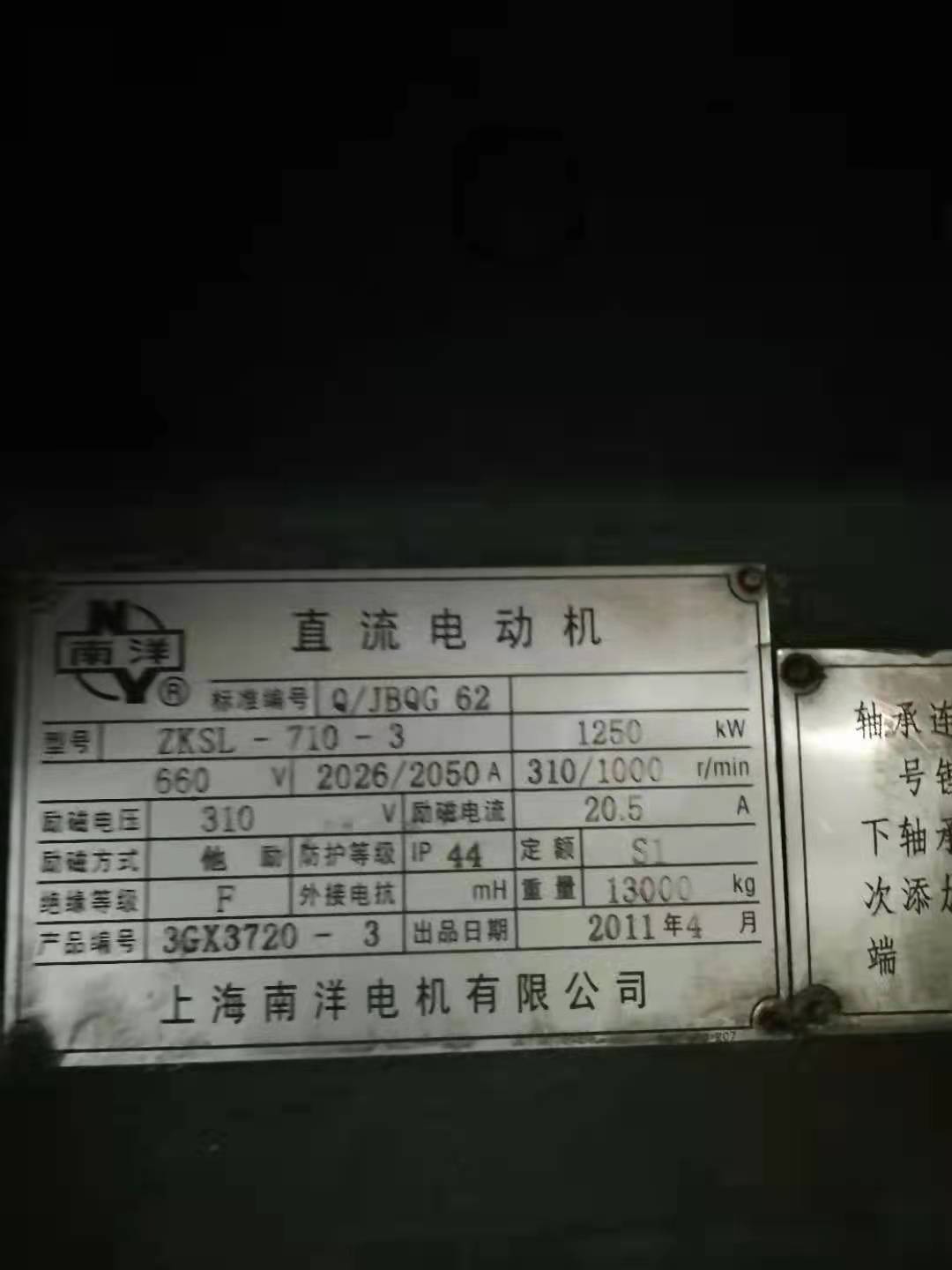

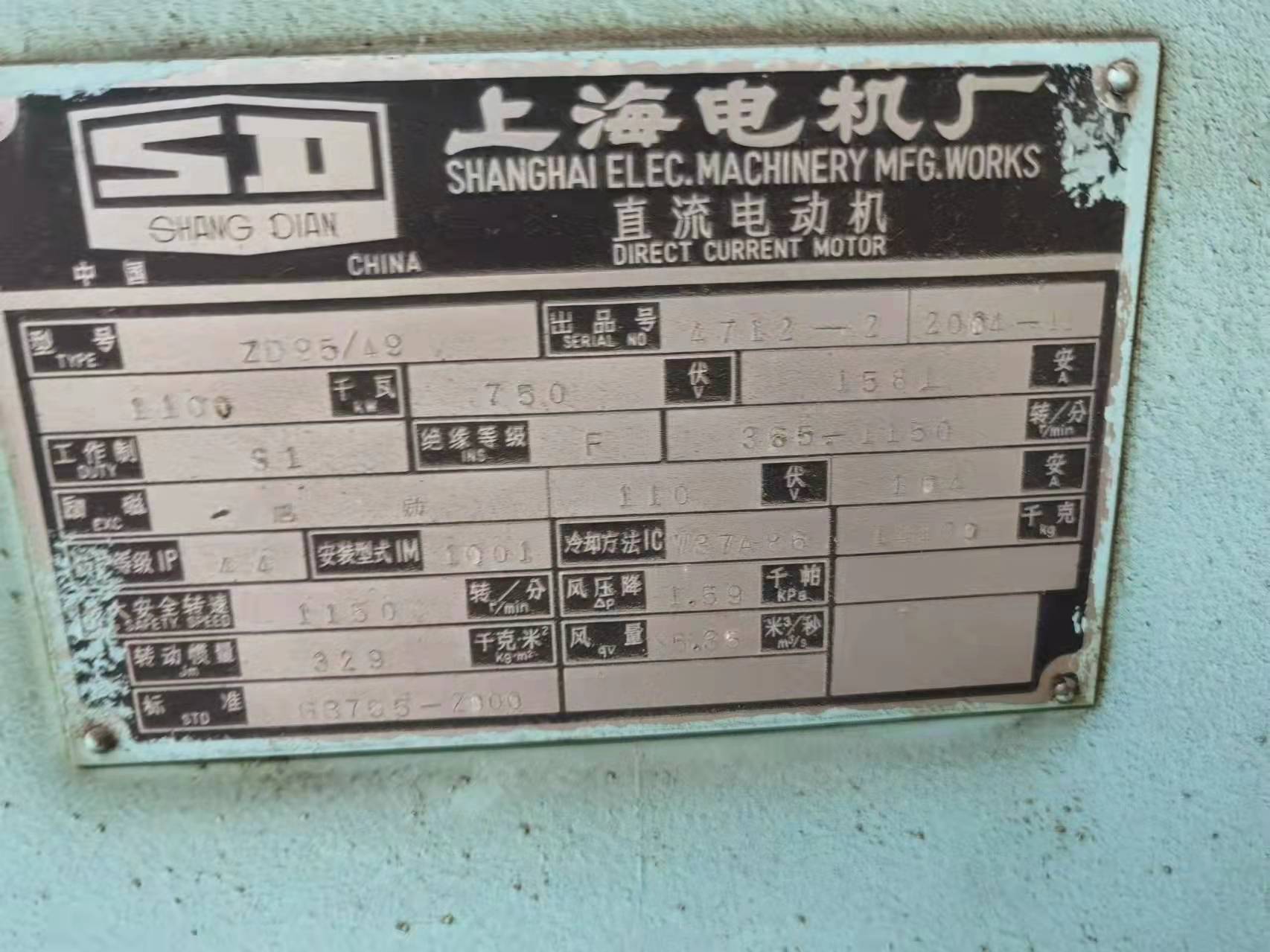

25. Transmission mode: DC transmission

26. Total softened water: (softened water grade: 100mg/l) 3M ³/ h(Max.)

27. Compressed air consumption: 5-6m ³/ Min (pressure: 6-8kg/cm3)

28. Total capacity of main drive motor: ~ 886kw

29. Total capacity of auxiliary drive AC motor and electric heating: ~ 700kW

1.1.3 Uncoiling and centering device

It adopts double-sided optical head detection, and the optical head automatically

finds the center when centering, and includes the center line deviation function.

1.1.4 1# pinch shear

Usage: used for opening coil, clamping aluminum plate and cutting head

Structure: with inlet feeding plate and upper cutting shear

Parameter: pinch roll upper roll size: lifting steel roll OD250*1450mm 1 PCS

Size of lower roll of pinch roll: one fixed rubber roll OD250*1450mm

Upper pinch roll lifting cylinder: OD60*30mm 2 PCS

Lower pinch roll drive motor: BM3 (hydraulic motor)

Lower roll overrunning clutch: 1

Cutting form: upper knife moving, lower knife fixed

Cutting edge width: 1450mm

Opening degree of cutting edge: 120mm

Shear cylinder: OD150/OD75*135mm 2

1 telescopic movable guide platform (driven by oil cylinder)

1.1.5 Disc shear (including flattening device)

Usage: cut the strip to the crack edge or to the finished width to ensure the width tolerance

Form: double frame, adjustable opening, cutter head side clearance, and manually adjustable overlap

Parameter: shear thickness: 0.2-1.2mm with disc knife

Disc cutter size: od170mm

Shear width: 700-1300mm

Opening adjustment: the motor drives the screw rod

Shear opening drive motor: s62-y1.1-4p-95.4-w

Shearing accuracy: ± 0.3mm

Width of waste edge: max. =50mm

Shear main drive motor: DC 10kw

Flattening roll: od160*1450mm

Butterfly shear for 0.1-0.2mm

Butterfly shear size: OD170mm (fixed knife)

Drive motor: Y2-801-4,0.55kw,1500 r/min

1.1.6 Waste edge winding machine

If you want to quote or further information on this product, please fill out the form below.

Previous:2004 1700mm 4hi cold rolling mill IHI

Next:2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

-

Dec. 2007 Chinese brand OD1250mm roll grinder

Dec. 2007 Chinese brand OD1250mm roll grinder

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

-

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

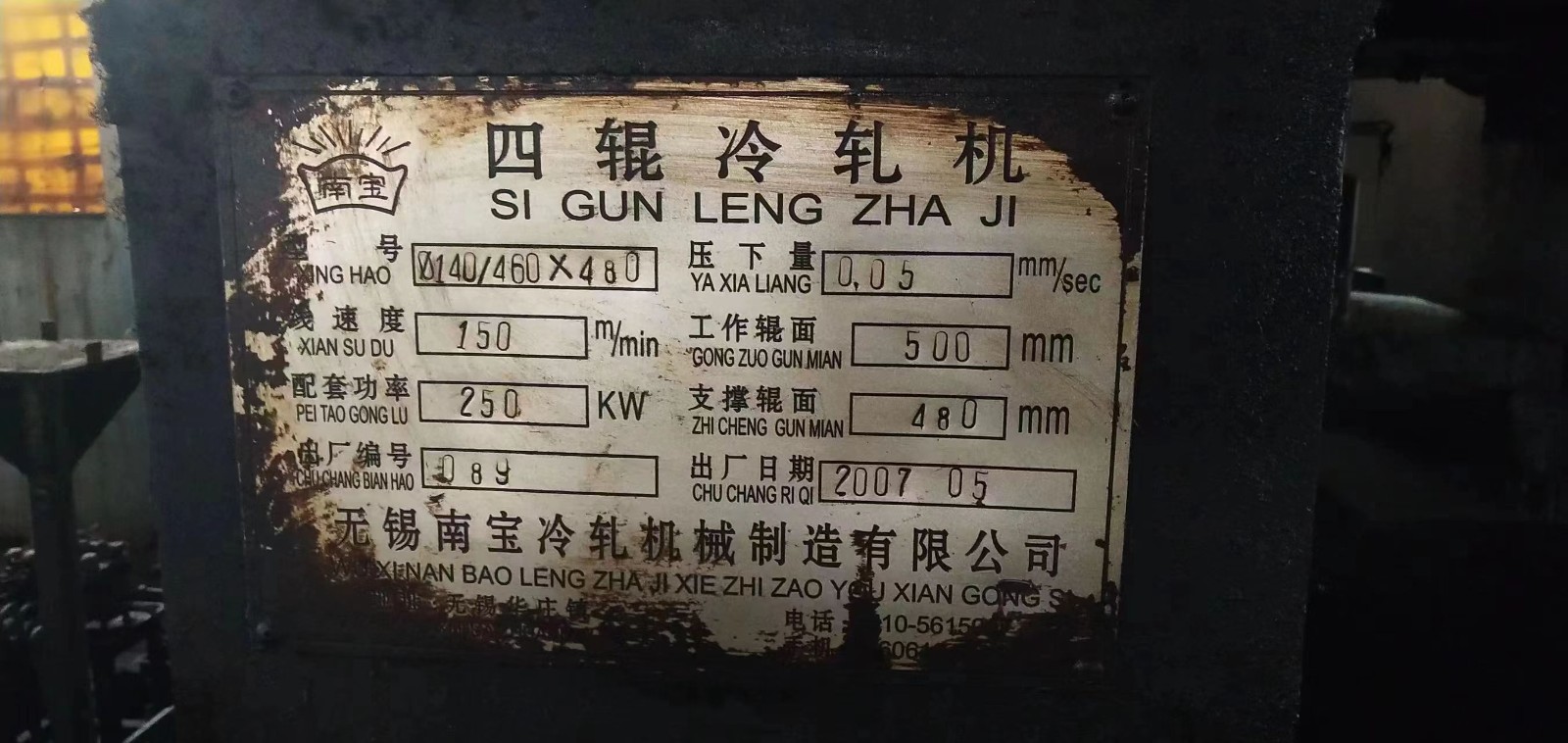

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

-

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

-

TL No.84 Used 1250mm Tension Leveler

TL No.84 Used 1250mm Tension Leveler

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

2017 750mm 6hi CRM AGC

2017 750mm 6hi CRM AGC

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

2006 Wuxi Jinjie 250mm 4hi CRM

2006 Wuxi Jinjie 250mm 4hi CRM

-

used aluminun tension leveler line

used aluminun tension leveler line

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

2006 MCC5 700mm 6hi cold rolling mill

2006 MCC5 700mm 6hi cold rolling mill

-

Mitsubishi 1050mm Tin plate cold rolling mill

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

2008 TMEDI 1250mm 20hi CRM Stainless Steel

2008 TMEDI 1250mm 20hi CRM Stainless Steel

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

480mm cold rolling mill

480mm cold rolling mill

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

2005 Chinese brand 550mm 4hi cold rolling mill

2005 Chinese brand 550mm 4hi cold rolling mill

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

No.185 Used 1300mm aluminum cold rolling mill

No.185 Used 1300mm aluminum cold rolling mill

-

2004 1700mm 4hi cold rolling mill IHI

2004 1700mm 4hi cold rolling mill IHI

-

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

-

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

used 600mm 20Hi cold rolling mill

used 600mm 20Hi cold rolling mill

-

2007 Chinese brand 700mm 4hi stainless steel CRM

2007 Chinese brand 700mm 4hi stainless steel CRM

-

2006 China First Heavy 6hi 2 stand reverse CRM

2006 China First Heavy 6hi 2 stand reverse CRM

-

2011 Chinese Brand 1250mm 20hi CRM

2011 Chinese Brand 1250mm 20hi CRM

-

CR No.168 used 4hi reverse cold rolling mill

CR No.168 used 4hi reverse cold rolling mill

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

2008 Shanghai Machine Tool OD1250mm Roll Grinder

2008 Shanghai Machine Tool OD1250mm Roll Grinder

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill