Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

Cold Rolling Mill

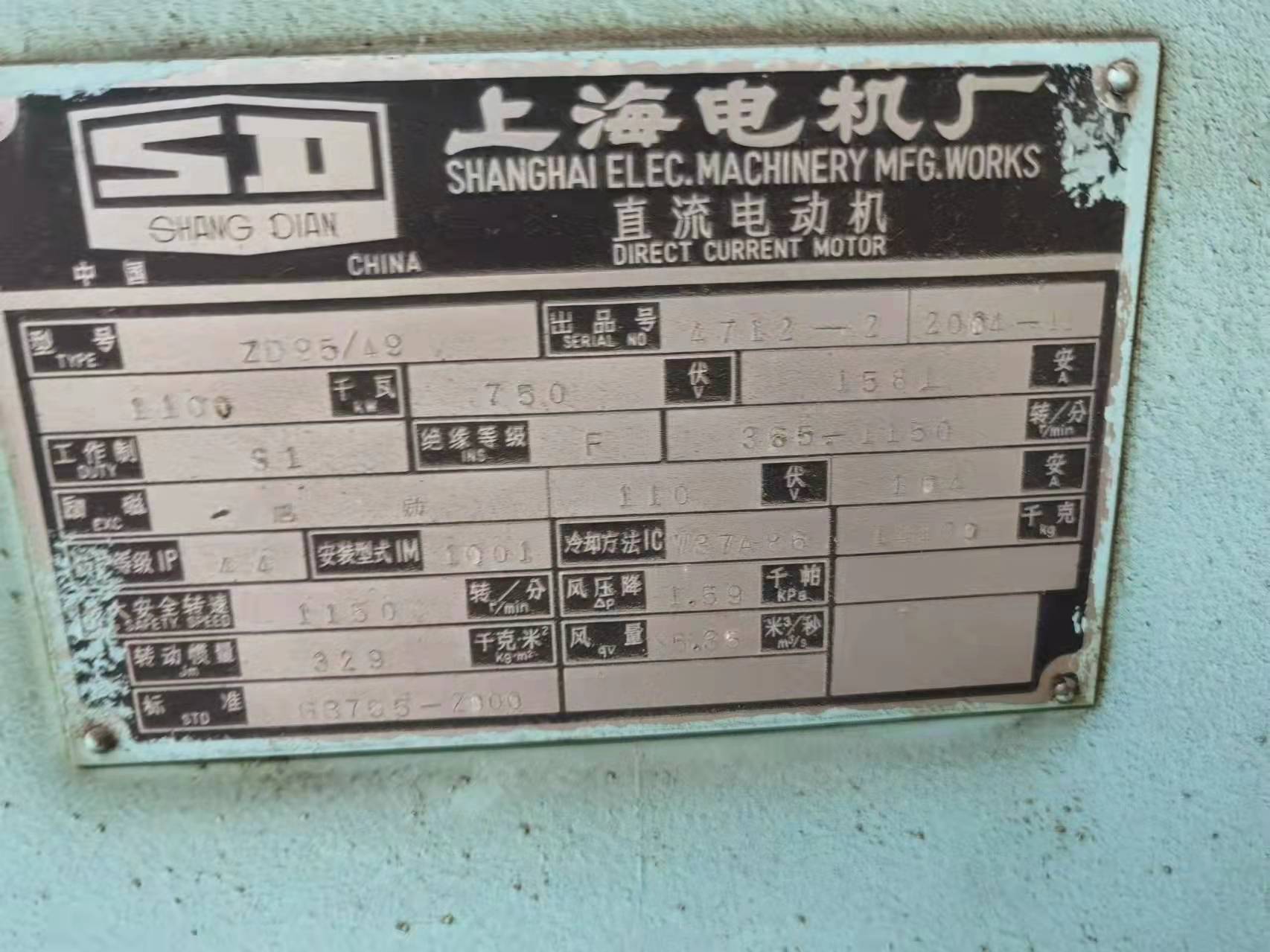

No.188 New 1150mm cold rolling mill

It is new machine. The written time is June 28,2021.- product description

- Technical Parameters

Machine performance

2.1 incoming material specification

Materials: pickling hot rolled coil Q195, 08Al, 20, SPHC, low alloy steel, etc

Maximum yield limit of mechanical properties σ s=360 N/mm2

Thickness 1.2-4 mm

Width 750-1015 mm

Coil diameter (inside / outside) Φ510 ×Φ 900-1800 mm

Maximum coil weight 18 t

2.2 finished product size

Thickness 0.18-1.2 mm

Width 750-1015 mm

Coil diameter (inside / outside) Φ 510/ Φ 900-1800 mm

Maximum coil weight 18 t

Thickness tolerance ± 0.005mm δ< 0.3mm

± 0.008mm 0.3≤ δ< 0.5mm

± 2% δ mm δ ≥0.5mm

3、 Main technical parameters

Mill specifications Φ 950/ Φ 370/ Φ 300 × 1150 mm

Maximum rolling pressure 11000 kn

Maximum rolling torque 80 kn. M

Belt piercing speed 18 m/min

Rolling speed 0 ~ 780 M / min

Uncoiling tension 5-50 kn

Coiling tension 12-120 kn (first gear, V < 450m / min)

6.3-63 kn (gear II, V ≥ 450m / min)

Maximum coiling speed 800 m/ min

Single side bending force of work roll (positive / negative) 300 / 180 kn

Intermediate roll traverse force 550 / 350 kn

Working roll diameter Φ 300- Φ 270 mm

Diameter of intermediate roll Φ 370- Φ 335 mm

Backup roll diameter Φ 950- Φ 890 mm

Length of working roll body 1150 mm

Intermediate roll displacement 200 mm

Maximum opening of working roll 20 mm

Uncoiler drum diameter Φ 460-520 (full circle) Φ 510)

Coiler drum diameter Φ 490- Φ 510 mm (full circle) Φ 510mm)

Axial floating amount of Uncoiler drum ± 75 mm

Diameter of lower pinch roll of head straightener Φ 400 mm

Guide roller diameter Φ 400 mm

Rolling line elevation +1000 mm

Adjustment stroke of rolling line elevation 125 mm

Process lubrication flow 6000 L / min

Working pressure of hydraulic system

Balance, roll bending, traverse, press up 21 MPa

General hydraulic transmission 10 MPa

The transmission direction of the mill is on the right side of the strip forward direction of the blooming pass.

4、 Unit installed level

4.1 Siemens DC speed regulation, SCR power supply (mixed structure) and PLC control are adopted for main rolling mill, uncoiler and front and rear coiler.

4.2 automatic thickness control (AGC) is performed by computer when fully hydraulic pressure is pressed. The hydraulic AGC system is controlled by two-level computer, which has the functions of constant roll gap, constant rolling force and thickness monitoring.

4.3 rolling mill has control means of pressure reduction deviation, positive / negative bending of working roll and positive bending of intermediate roll; The shape control means of the intermediate roll transverse setting and roll cooling.

4.4 the uncoiler has CPC automatic centering function.

4.5 quick roll change of working roll and intermediate roll.

4.6 the rolling mill electrical system has overload protection, strip breaking protection and emergency stop and other safety protection systems; The main machine and coiler have the functions of automatic deceleration with tail and accurate stop; The coiler has the function of circle number memory.

4.7 rolling mill speed control: speed / tension control of Uncoiler and coiler, digital display.

4.8 the rolling line elevation is adjusted quickly by electric pressing screw.

4.9 oil and gas lubrication of rolling mill bearings.

4.10 PLC programmable control is adopted for the production process interlock and fault alarm of the unit to realize the automation of production process.

4.11 the unit has the pre setting of process parameters, detection, display and alarm system of process parameters and key equipment parameters.

If you want to quote or further information on this product, please fill out the form below.

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

used 1250 4HI irreversible cold rolling mill aluminum

used 1250 4HI irreversible cold rolling mill aluminum

-

KOBELCO used cold rolling mill 1300mm Aluminum

KOBELCO used cold rolling mill 1300mm Aluminum

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

-

1250mm 6hi revisible cold rolling mill

1250mm 6hi revisible cold rolling mill

-

cold rolling mill working rolls

cold rolling mill working rolls

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

used tension leveler aluminum

used tension leveler aluminum

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum

-

Used 1250 6hi reverse cold rolling mill in Shanghai, China

Used 1250 6hi reverse cold rolling mill in Shanghai, China

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

2011 used 1700mm cold rolling mill aluminum

2011 used 1700mm cold rolling mill aluminum

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

-

used Kobelco cold rolling mill aluminum 1300mm

used Kobelco cold rolling mill aluminum 1300mm