Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill, model No.:207, it is written on Jan.5,2022

- product description

- Technical Parameters

A. Basic information

1. Equipment name: MSB-6C-1250 six high reverse cold rolling mill

2. Purpose of the unit: the unit has a thickness of 2.0-4.5mm, a width of 800-1270mm and a material of the hot rolled strip of low carbon steel and medium and low grade silicon steel is rolled in necessary passes with a thickness of 0.20 ~ 1.2mm.

The product quality of the cold rolling mill finished products shall not be lower than that of GB / T716-1991, GB / T5213-2001,the highest standard of GB / T2521-1996.

B. Main performance parameters of the unit

2.1 incoming material specification

Material: pickling hot rolled coil: low carbon steel, medium and low grade silicon steel, etc

Mechanical properties: maximum yield limit σS≤360N/mm

Thickness: 2.0-4.5 mm

Width: 800-1270 mm

Coil inner diameter: Φ 610 mm

Coil outer diameter: Φ 800- Φ 2000mm

Unit maximum coil weight: ≤ 20kg / mm

Coil weight: Max 25T

2.2 finished product size

Thickness: 0.20-1.2mm

Width: 800-1270mm

Coil inner diameter: Φ 610 mm

Coil outer diameter: Φ 800- Φ 2000mm

Coil weight: Max 25T

2.3 main technical parameters

1. Main rolling mill

Mill model: MSB-6C-1450

Maximum rolling pressure: 20000KN

Maximum rolling torque: 150KNm

Rolling speed: 0 ~ 1000m / min

Threading speed: 18m / min

Uncoiling speed: 400m / min

Uncoiling tension: 70KN

Maximum coiling tension: ≤ 10m / s 20 ~ 200KN

≥10m/s 12.5~125KN

Uncoiler drum diameter: Φ 620mm (round Φ 610)

Coiler drum diameter: Φ610 mm/Φ590 mm (full circle Φ610)

Work roll size: Φ400 mm/Φ360 × 1450 mm

Intermediate roll size: Φ450 mm/Φ410 × 1400 mm

Support roll size: Φ1250 mm/Φ1190 × 1350 mm

Traverse of intermediate roll: 330 mm

Opening: 25m

Bending force of work roll: + 400kN / - 300KN

Bending force of intermediate roll: + 400kN

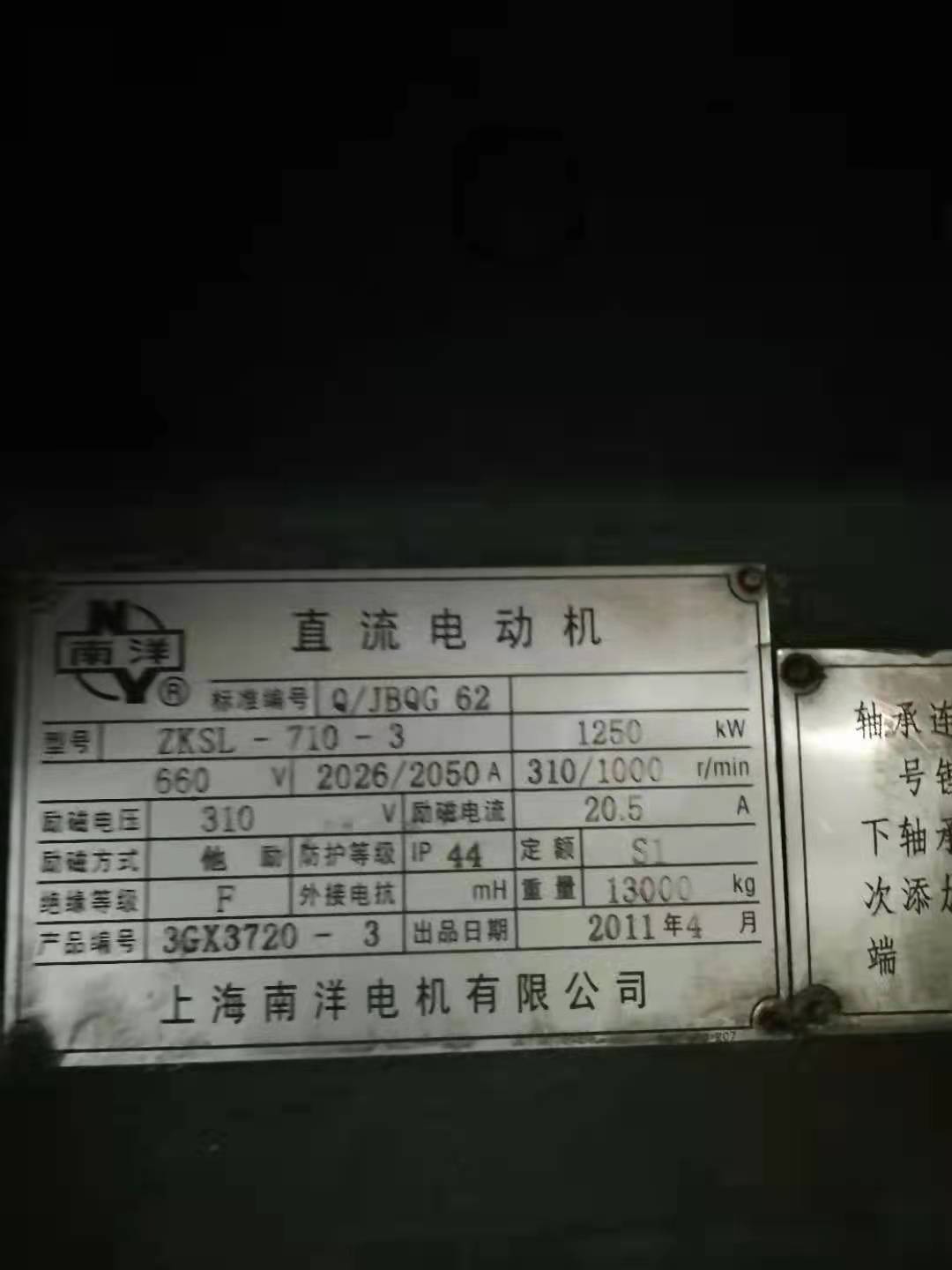

Main drive motor: 4 × 1250KW (0~1000m/min)

Coiler motor: 2 × 2 × 1250KW (0~1000m/min )

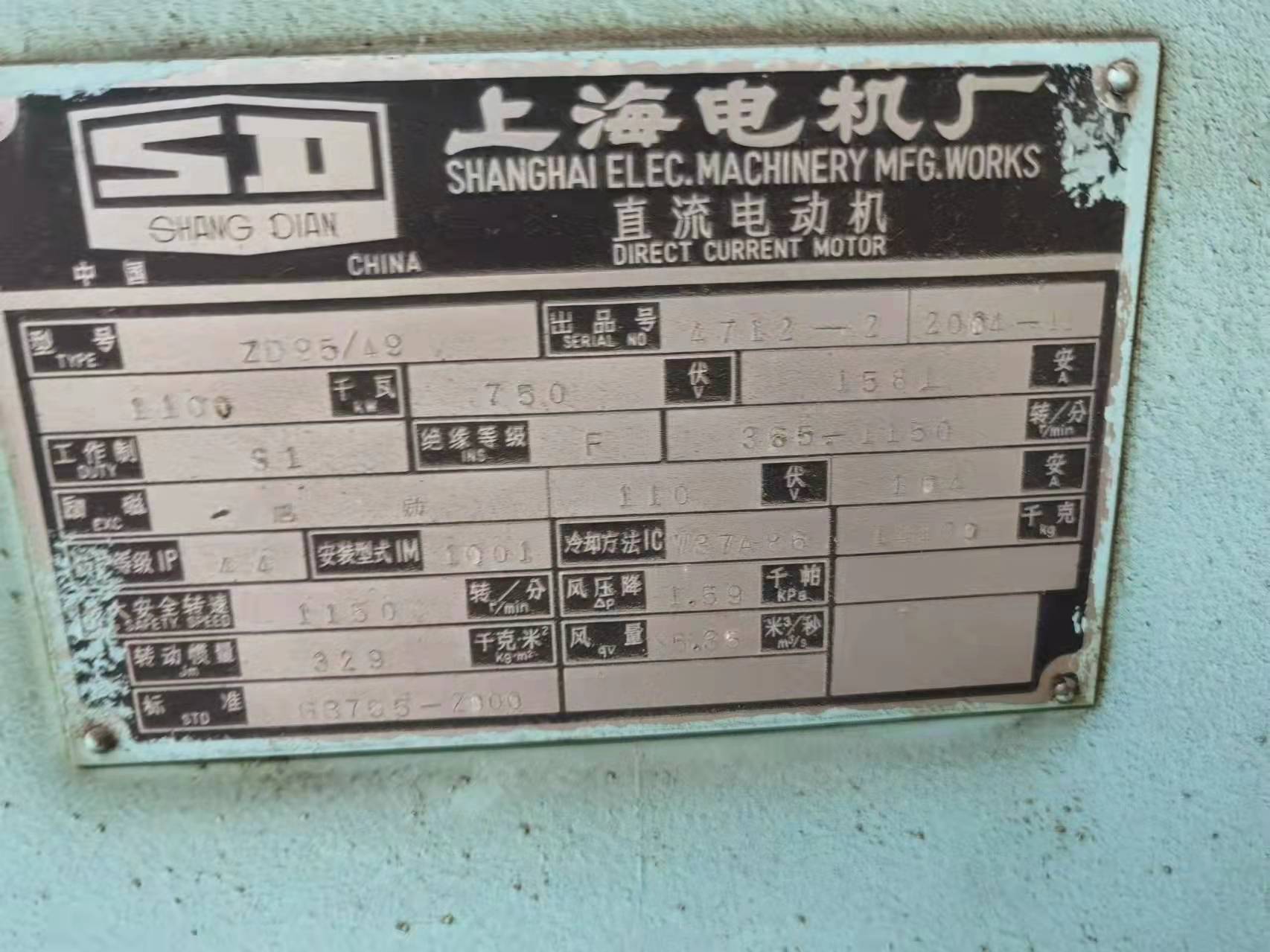

Uncoiler motor: 618kw

Pressing mode: hydraulic pressing

Product accuracy: ≤± 1.5% H

Process lubricating medium: emulsion

Process lubrication flow: 100,00l / min

Working mode of the unit: coil reversible rolling

Uncoiling direction of the unit: right uncoiling (facing the operation side of the rolling mill, and the uncoiler is on the right side of the main rolling mill)

2. Uncoiler

Drum: nominal diameter φ 610mm

Maximum speed: 400m / min

Tension: Max.70 kN

Transmission motor power: 618kW × 1 set (DC)

3. Coiler before and after rolling mill

Drum: φ 610mm

Speed: ≤ 600m / min. (tension: max.200 kN)

Speed: ≥ 600m / min. (tension: max.125 kN)

Power of transmission motor: 1250kW × 2 sets (DC)

2.4 product outline (provided by the buyer)

Steel grade and specification(mm) | Low carbon steel, medium and low grade silicon steel | Plate width | |

% | 10,000 tons | 1,250 | |

0.35 | 10 | 2 | |

0.50 | 80 | 16 | |

0.65 | 10 | 2 | |

total | 1.5 | 100 | 20 |

2.5 output calculation of rolling mill

(1) Rolling mill capacity calculation.

(2) Refer to the rolling table for the calculation of each specification.

2.5.1 working conditions

(1) Skilled operator.

(2) Stable and qualified raw materials.

(3) Sufficient spare parts to ensure continuous production.

2.5.2 calculation premise

(1) Maximum speed: 1000m / min;

(2) Representative material 50W540;

(3) The unit average coil weight is 20kg / mm;

(4) The specific specification calculation for reference is shown in table 1-5 of the rolling specification:

(5) Excluding the inspection operation of strip steel surface;

(6) The pre uncoiling of the steel coil on the uncoiler and the threading time of the upper channel are not considered.

2.5.3 rolling time

(1) Calendar time of one year (Tc): Tc = 365 days × 24 h / day = 8760 h / y

(2) Planned maintenance time: 26 times × 16h=416 h/y (including backup roll change)

(3) Overhaul time: 12 days × 24 h=288 h/y

(4) Work roll and intermediate roll change: 3 times × 335 days × 0.25 h=251 h/y

Unit shutdown time: Σ= 416+288+251=955 h/y

Unit working time (Tw): Tw = 8760h-955h = 7805 h / y

(5) Net working time (Tr)

Net working time (Tr) = unit working time × Unit efficiency

(unit operation rate includes unforeseen shutdown time, such as belt breaking time)

Tw=7805 × 0.83=6500 h/y

If you want to quote or further information on this product, please fill out the form below.

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

2011 Chinese Brand 1250mm 20hi CRM

2011 Chinese Brand 1250mm 20hi CRM

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

Mitsubishi 1050mm Tin plate cold rolling mill

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill