Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

2011 Chinese Brand 1250mm 20hi CRM

stock No.: 216, it is written on April 14, 2022- product description

- Technical Parameters

Machine is made in 2011

Machine is dismantled in October, 2021

1.1 Power supply data

- Frequency 50Hz ± 10%

- High voltage 10kV ± 10%

1.2 compressed air

- The pressure is 0.5 ~ 0.8MPa,

- Oil content < 1ppm

- Atmospheric dew point < = - 40 ℃

2.1 Product size

Material: stainless steel, carbon steel

- strip width

·1250mm Max

·Minimum 700mm

- Maximum coil weight 20 t, excluding sleeve

- Coil size

·Inner diameter 610mm

·Maximum outer diameter 2000mm

·Minimum outer diameter 900mm

- Raw material thickness < = 3.5mm

- Finished product thickness : > = 0.1mm

Max. speed: carbon steel 600m/min

stainless steel: 400m/min

3.1 Roll

Working roll:Ф63.5*1444;Material: cr12movgo

Working roll quantity: 2

- Diameter range

- Min. 58 mm

- Max. 73.5mm

- Hardness 60-62hrc

- Grinding depth per week: > = 0.05mm 1st

Driving roll: Ф102 * 1550mm material: 5cr5wmosiv

Driving roll quantity: 4

- Diameter range

Min.: 96mm max.: 102mm

- Hardness 58-58hrc

- Roughness: ra1

- Grinding depth: 0.1mm second

Back up roll: Ф173 * 1586mm material: 5cr5wmosiv

Back up roll quantity: 14

- Diameter range Min: 170mm Max: 173mm - Hardness 58-60hrc - Roughness: ra1 - Grinding depth: 0.1mm 3.2 arrangement of rolling mill | |

- Rolling direction | Right to left |

- Rolling line height of rolling mill | +1100mm |

- Distance between uncoiler and left tension coiler | 8000mm |

- Tension coiler elevation | +640mm |

- Uncoiler elevation | -200mm |

- Distance between tension coilers 3.3 main parameters of equipment - Uncoiler - Drum diameter | two×4650mm=9300mm |

*Nominal | +610mm |

*Shrink | 548mm |

*Expansion tension: | 634mm |

*Maximum - speed: | 70kN until 400m / min |

*Threading | 25 M / min |

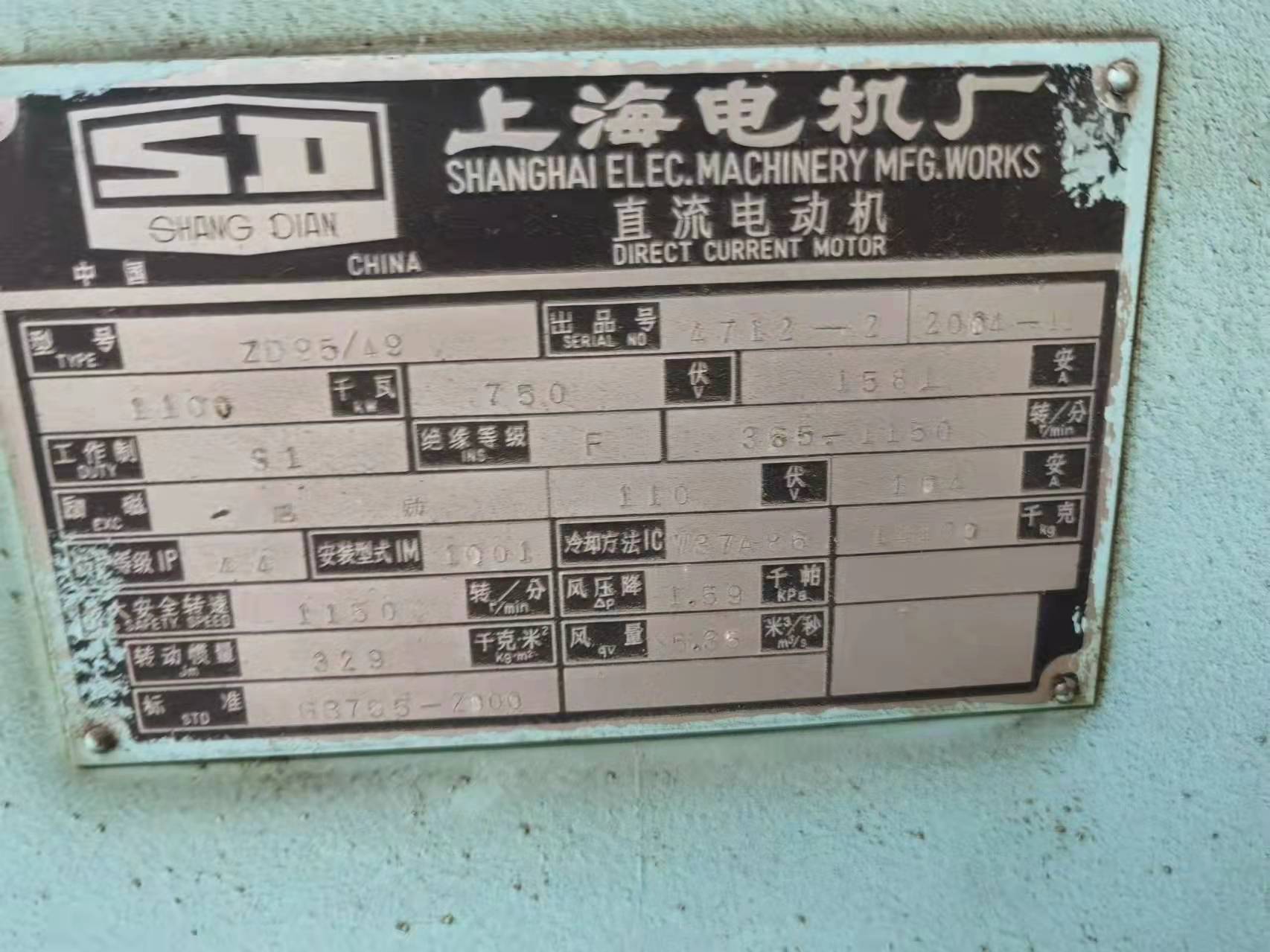

*Max. (rolled) - Drive motor: *AC motor | 300 M / min |

*Power | 510KW |

*Speed | 0/310/1000 RPM |

*Gear reduction ratio | 1:6.43 |

- Pinch straightener

·Drive motor: * DC motor

*Power 30KW

*Speed 1500 rpm

·Gear reduction ratio 28 / 1

·Roll diameter 200mmMain parameters of rolling mill

- rolling mill

·Archway model ·Drive motor: | Zgm1400 "negative convexity" |

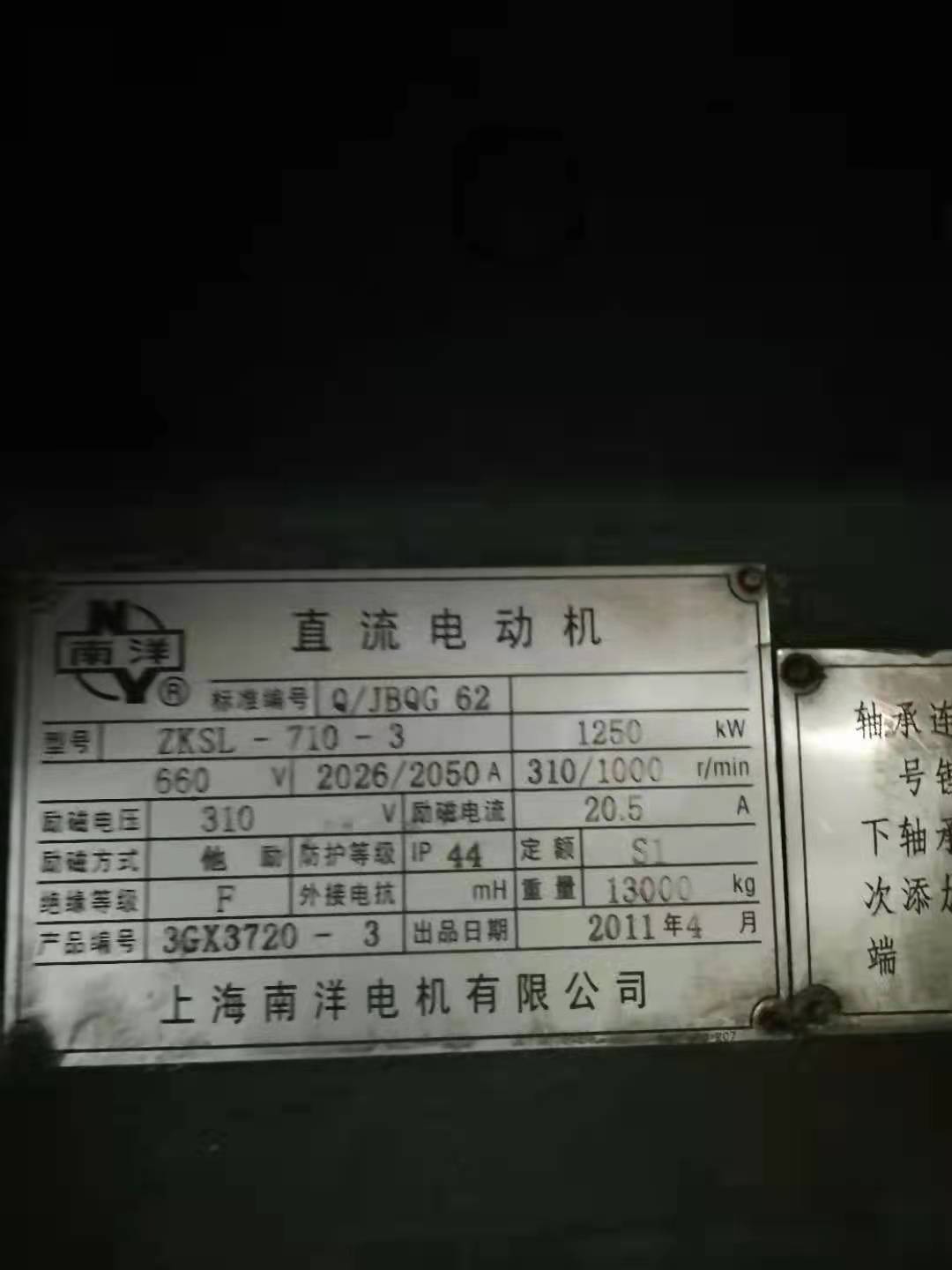

*DC motor | ZKSL710-3A |

*Power | two×1250KW |

Rated voltage | 660V |

Rated current | 2050A |

*Rotation speed | 310/1000 RPM |

*Linear velocity | 0/300/600 M / min |

Overload multiple | 2.5/1 |

·Maximum speed - Tension coiler ·Drum diameter | 800 M / min |

*Over expansion | 615mm |

*Standard | 610mm |

*Shrink ·Drive motor: | 595mm |

*DC motor | ZKSL710-3A |

*Power | two×1250KW |

Rated voltage | 660V |

Rated current | 2050A |

*Rotation speed | 310/1000 RPM |

*Linear velocity | 0/400/800 M / min |

Overload multiple | 2.5/1 |

·Maximum speed | 800 M / min |

·Tension

*450kn at 600m / min *350kn at 800m / min

*30KN, min

- Steering roll

·Drive motor:

*Acvf motor

*Power: 7.5kw

*Speed 0 / 637 rpm

*Direct drive

- Structure negative convexity structure

- Type zgm1400

- Maximum rolling force 8000kN

- Mill stiffness 4800kn / mm

- Material cast steel

- Manual door opening

- Locking hydraulic pressure

- the maximum roll gap of the working roll under the nominal roll diameter is 6.833mm

- Support bearing

Type eight groups number on each axis 6 total 48

Outer diameter 300mm, inner diameter 130mm, width 172.6mm

- Saddle

Saddle spacing 215.9mm (8 1 / 2 ") saddle clamping operation manual wrench lateral adjustment (push-back type)

In order to release the load on the opposite side of the strip, only a certain taper is provided on the middle side of the pair of rollers.

technical data

- Lateral adjustment operation | 2 Two hydraulic cylinders with diameter of 110 / 80mm and stroke of 200mm |

Lateral adjustment range | 200mm |

Hydraulic pressure of cylinder | 20Mpa |

The adjustment of an intermediate roll must be performed under the condition that the speed is greater than 0.5m/s

Through the rotation and positioning of the two upper support rollers "B" and "C", the rack is driven by the hydraulic cylinder and the gear rod meshed with the gear installed at the shaft end controls the main pressure.

A servo valve is installed above the hydraulic cylinder to avoid absorbing air.

Press up and down to install emergency opening.

An MTS displacement sensor is installed on the upper holding down cylinder on the operation side to cooperate with the servo valve to control the displacement of the holding down cylinder

Pressure and location technical data | |

- Up and down operation | 2 Hydraulic cylinder diameter 224 / 140mm |

·Up and down stroke | 132mm |

·Eccentricity - Open data ·Opening speed on hydraulic cylinder: | 6.35mm |

*Low speed | 20mm / S |

*High speed ·Opening time | 150mm / sec |

*Low speed | 7 second |

*High speed | 0.9 second |

Elevation adjustment of rolling line

Through the rotation of two sets of lower backup rolls "F" and "g", the position of the lower work roll can be adjusted according to the relationship with the pass line of the rolling mill.

These shafts are hydraulically rotated through gear rods and transmission gears in the same way as pressing up and down, but they are only operated under "no-load" conditions with the help of hydraulic cylinders located under the mill housing on the operating side.

technical data

- Elevation adjustment operation of rolling line | 2 Hydraulic cylinder, operating side Diameter 100 / 56mm, stroke 132mm |

- Rolling line control | 1 Linear sensors |

- Eccentricity (F and G) | 6.35mm |

Side eccentricity adjustment

The two outer shafts "a" and "H" and the other two outer shafts "d" and "e" are meshed together respectively and can be rotated by hydraulic motor, so as to make the two upper and lower rollers of the roll group close together and compensate for the reduced roll diameter.

Adjust only under "no load" conditions.

technical data

- Side eccentric adjustment | 2 Hydraulic cylinder with absolute encoder |

- Operation instruction | 2 Digital readout device |

- Eccentricity a, D, e and H | 3.175mm |

"As-u-roll" crown adjustment

A function to change the relative height of each bearing is provided on the "BC" and "FG" shafts, so that the operator can increase or reduce the amount of crown and wedge in the rolling mill. This is achieved through the double eccentric structure of the saddle, which can be realized by using these shafts that the toothed rod rotates alone.

technical data

- Crown adjustment operation | 7 Hydraulic cylinder, 80mm diameter The stroke is 160mm and the working stroke is 79mm |

- Convexity control | 7 Linear sensors |

- install | Installed on plate cylinder |

- Eccentricity | 1.016mm |

Thickness gauge (X-ray)

- Two thickness gauges are installed on the guide roll base on each side of the mill housing.

4auxiliary equipment

- hydraulic equipment

It is equipped with two hydraulic devices to serve the rolling mill and its auxiliary equipment. The first one is used for main screw down device, lateral adjustment and

Operation of s-u-roll. The first one is used for the operation of all other functions. The intermediate piping and on-board piping are made of stainless steel.

Technical data high pressure pump station

- number of pumps | 2(1 + 1 standby) |

- pump flow | 145 L / min |

- pump type | The variable pump |

- AC drive | 55kW at 1500 rpm |

- working pressure | 21Mpa |

- tank capacity | 1000 rise |

- fuel tank material | stainless steel |

- heating device | three×2 kW =6kW |

- filter circulating pump on return pipe | tenμ |

- number of pumps | 1 |

- pump flow | 85 L / min |

- pump type | Spiral type |

- working pressure | 0.5Mpa |

- motor power | 2.2kW at 1500 rpm |

- filtering | fiveμ |

CPC pump

- number of pumps | 1 |

- pump flow | 52 L / min |

- pump type | Spiral type |

- working pressure | 15Mpa |

- motor power | 15kw at 1500 rpm |

- filtration accuracy medium pressure pump station | fiveμ |

- number of pumps | 3(2 + 1 standby) |

—N=55KW | n=1480r/min |

PM=15Mpa | Qm=140L/min |

Pl=7 Mpa | Qm=95L/min |

Oil tank volume: 3000l | Medium: Sinopec lm46# anti-wear hydraulic oil; Temperature: 15 ∽ 50 ° C |

Thin oil station

Three pumps, two for use and one for standby under normal conditions, oil tank volume: 10000l

Medium: 220# closed heavy-duty gear oil

Pump motor: n = 11kw |

P=0.4—6 M P a |

low: q = 40 L / min | Temperature 15 ∽ 30 ° C |

Emulsion filtration system

It is divided into reflux box (including compressed air purging and magnetic filtration), plate box and bearing lubrication box. There are two plate lubrication pumps, two lifting pumps and two bearing lubrication pumps.

Parameter pump

N=75KW | n=1480r/min |

Q= | P=0.6—0.8MPa |

Medium: (3-5)% rolling oil-water mixture | Temperature: 35-50 ° C |

One set of X ray thickness gauge

Total weight approximate: approximate 750 t

Exclude spare parts.If you want to quote or further information on this product, please fill out the form below.

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

Mitsubishi 1050mm Tin plate cold rolling mill

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill