Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

used aluminun tension leveler line

Model No.: 261, it is written on March 19, 2022- product description

- Technical Parameters

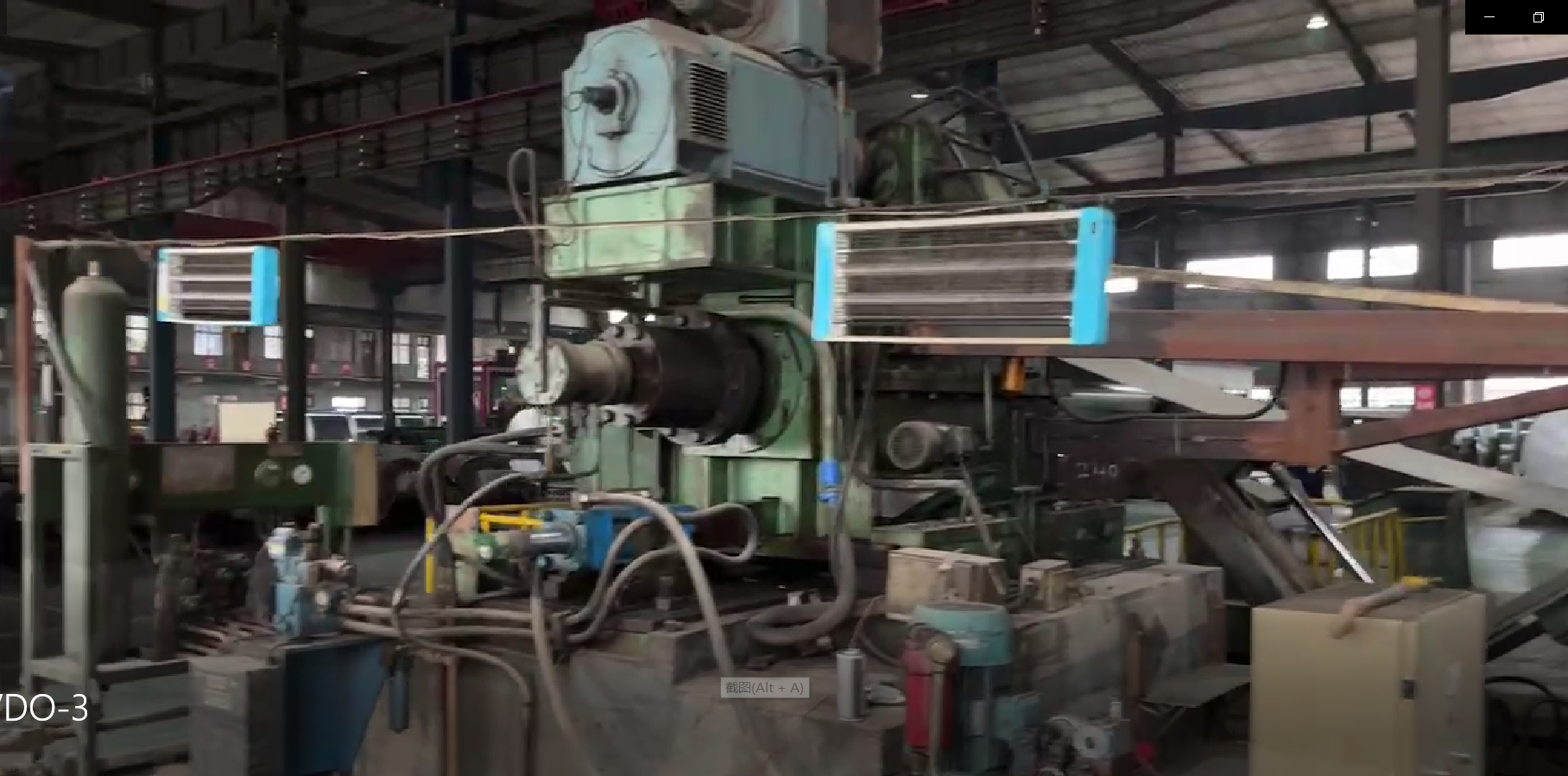

used aluminum tension leveler line

ⅠScope of supply

Material: aluminum plate

1 feeding trolley (including track)

Uncoiler 1 set

1 set of feeding roller (including feeding plate)

1 set of inlet tension roller

1 tension bending straightener body (manufactured according to the data provided by Party A)

1 set of outlet tension roller

Trimming shear 1 set

Edge material coiling 1 set

One reversing roller (including outlet feed plate)

Coiler 1 set

1 unloading trolley (including track)

1 set of hydraulic system (including piping)

ⅡMain technical indicators

Raw material: aluminum and aluminum alloy

Mechanical properties:бb (tensile strength) =40Kg§2;бs (yield strength)=35Kg§²

Thickness of raw materials: 0.08mm -- 1.0mm

Raw material width: 600mm -- 1320mm

Outer diameter of raw material roll: ≤φ1650mm

Trimming burr: ≤ 0.03mm

Weight of raw material roll: ≤ 6500kg

Coiling staggered layer: ≤ 0.6mm

Coiling tower shape: ≤ 1.0mm

There is no scratch on the board surface

Ⅲ Introduction to each single machine

1. Loading trolley

1.1 structural form: ground type

1.2 lifting mode: oil cylinder lifting, lifting speed > 50mm / min

1.3 forward and backward mode: oil motor drive

1.4 maximum outer diameter of coil:φ1600mm

1.5 maximum weight of roll: 6500kg

1.6 maximum stroke of oil cylinder: 350mm

1.7 traveling speed: ≤ 5m / min

2. Uncoiler

2.1 nominal diameter of drum:φ508mm

2.2 effective length of drum: 1450mm

2.3 bearing weight: ≤ 6500kg

2.4 expansion and contraction range of drum:φ475mm--φ518mm

2.5 DC motor power: 30kW (1500rpm; with encoder, model provided by electrical)

2.6 centering stroke: ± 100mm

2.7 reduction ratio: 21 (calculated by 160m / min)

2.8 theuncoiler adopts central drive (toothed chain mode), hydraulic expansion and contraction, and is equipped with pressing roller.

3. Feeding roller (including feeding support plate)

It is composed of two passive rollers with NBR on the surface and feed supporting plate.The relative position of the two passive rollers is fixed;The up and down swing of the feeding support plate is realized by the hydraulic cylinder;The feeding support plate is double-layer and has expansion function. The expansion amount is 400mm. The expansion action is realized by hydraulic cylinder.

4. Inlet tension roller

4.1 the inlet tension roller is composed of four rollers, and the reduction ratio of the equipped reducer is 16.

4.2 DC motor power:

A roll 18.5kw; B roll 22KW; C roll 30kW; d roll 37KW

4.3 the DC motor is 1500rpm;With encoder, the model is provided by the electrical.place

Roll diameter ≤φ600mm, 1450mm long roll surface, roll coated with polyurethane rubber, 15mm thick rubber layer, shore hardness 80 ± 5.

5. Tension bending straightener body

6. Outlet tension roller

6.1 the outlet tension roller is composed of four rollers, and the reduction ratio of the equipped reducer is 16.

6.2 motor power:

E roll 45KW ^ f roll 30KW ^ g roll 22KW ^ h roll 18.5w

6.3 the requirements are the same as those in Clause 4.3.

7. Edge trimming

7.1 effective feed channel width: 1450mm.

7.2 calculate the speed ratio according to the speed of 160m / min.

7.3 pinch traction mechanism: the position of the lower roll is fixed and it is a passive roll;The upper roller is the driving roller, which moves up and down driven by the hydraulic cylinder.

7.4 the upper and lower cutter shafts of the trimming machine are adjustable.

7.5 DC motor power: 7.5kW.

7.6 with four hob blades

8. Edge material coiler

There are two in total, symmetrically arranged.The AC motor drives the mechanical friction clutch through the reducer for edge material coiling

9. Reversing roller (including feeding support plate)

It is composed of a passive roll with NBR surface and a feeding support plate.The up and down swing of the feeding support plate is realized by the hydraulic cylinder.

10. Coiler

10.1 bearing weight: ≤ 6500kg

10.2 nominal diameter of drum:φ305mm、φ405mm、φ505mm three specifications;Various reels can be replaced with each other;The drum is not equipped with jaws.

10.3 effective length of drum: 1450mm

10.4 the coiler is equipped with a pushing device and auxiliary support, in which the inner hole of the pushing plate of the pushing device isφ505mm drum shall be subject to design.

10.5 DC motor power: 45KW (1500rpm; with encoder, model provided by electrical)

10.6 calculation basis of reduction ratio of coiler: drumφ405mm, linear speed 160m / min.

11. Unloading trolley

Same as loading trolley.

12. Hydraulic system (including piping)

12.1. The hydraulic system adopts Yuci oil research products jointly invested by China and Japan.Yuken/Yuci

12.2. It has oil pollution alarm function.

12.3. Main technical parameters of hydraulic control system

Maximum working pressure of the system: 7MPa

Rated working pressure of the system: 6.5MPa

Control voltage of solenoid valve: AC 220V

System medium: N46 anti-wear hydraulic oil (provided by the demander)

System cleanliness: nas11

Normal working oil temperature of the system: ≤ 55 ℃

ⅣMain external component suppliers

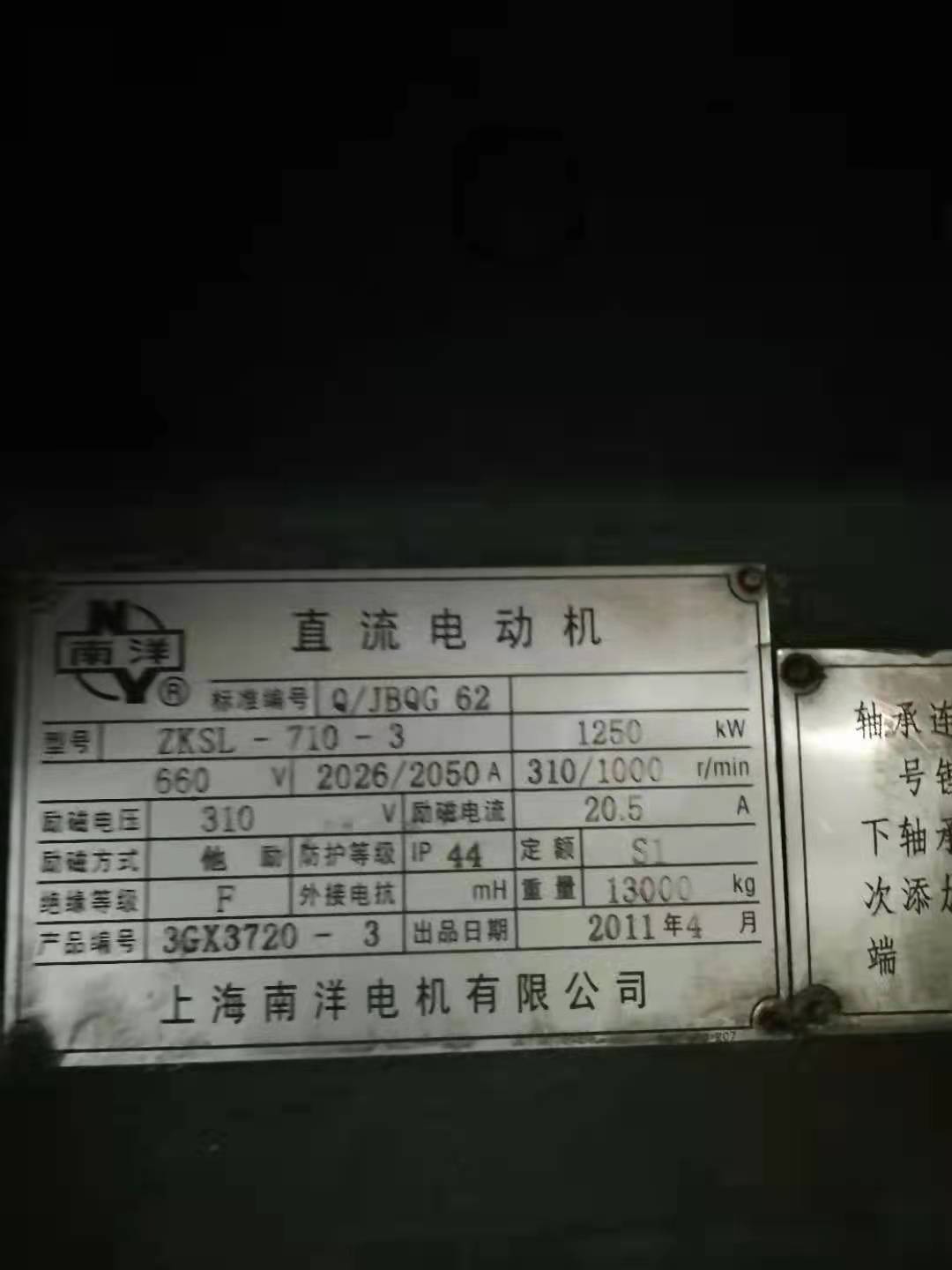

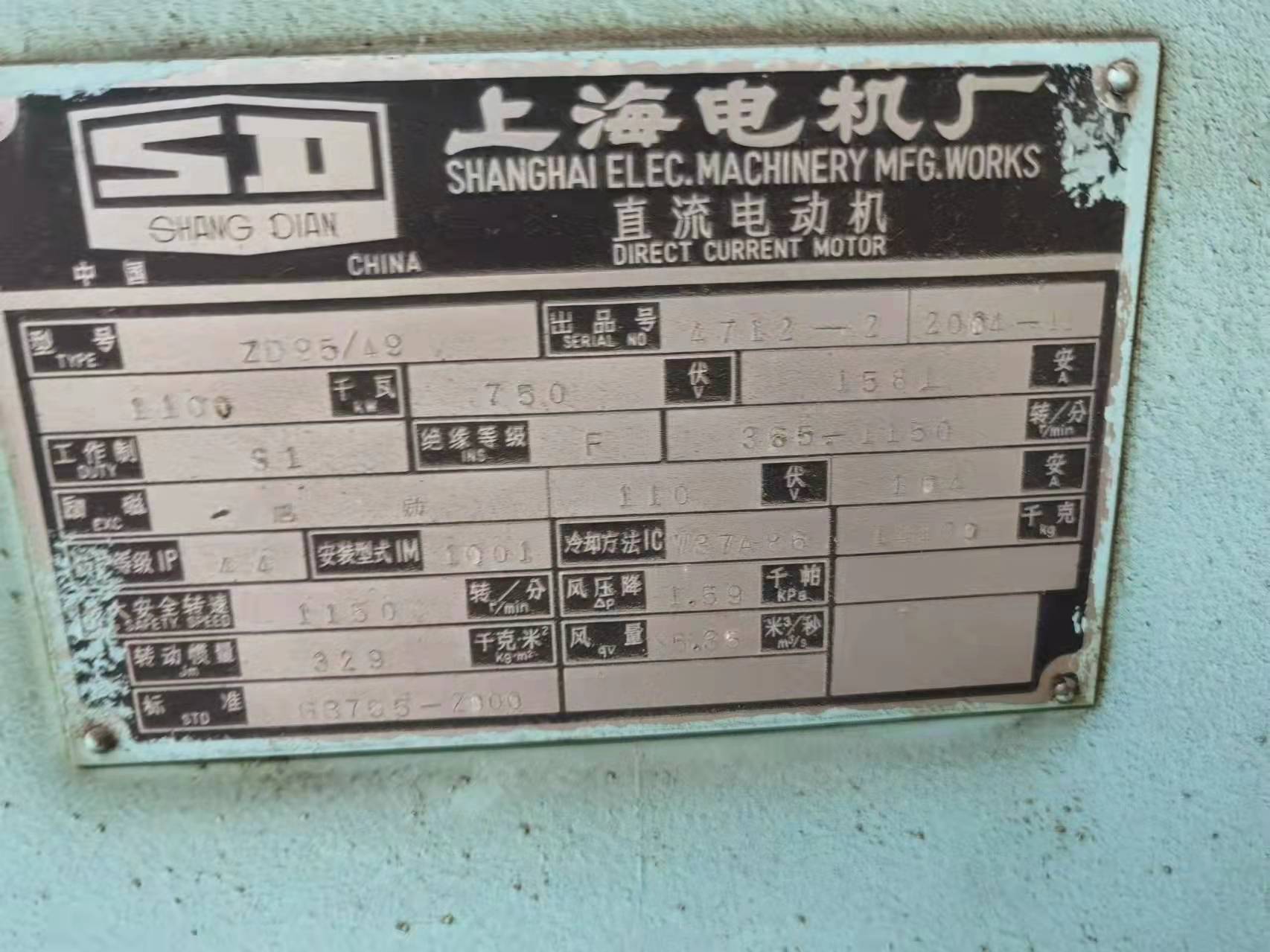

1. DC motor adopts Shanghai Nanyang;Rated speed 1500rpm, rated voltage 440V, excitation voltage 320v.

2. The oil cylinder adopts Tianjin Sifang, and the oil pressure is ≤ 7MPa.

3. The tension roller reducer adopts Hubei Jingzhou products, and the others adopt Qinchuan products.

If you want to quote or further information on this product, please fill out the form below.

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

-

2011 Chinese Brand 1250mm 20hi CRM

2011 Chinese Brand 1250mm 20hi CRM

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

CR No.168 used 4hi reverse cold rolling mill

CR No.168 used 4hi reverse cold rolling mill

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

2007 Chinese brand 700mm 4hi stainless steel CRM

2007 Chinese brand 700mm 4hi stainless steel CRM

-

2004 1700mm 4hi cold rolling mill IHI

2004 1700mm 4hi cold rolling mill IHI

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

2006 China First Heavy 6hi 2 stand reverse CRM

2006 China First Heavy 6hi 2 stand reverse CRM

-

Dec. 2007 Chinese brand OD1250mm roll grinder

Dec. 2007 Chinese brand OD1250mm roll grinder

-

2006 MCC5 700mm 6hi cold rolling mill

2006 MCC5 700mm 6hi cold rolling mill

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

2017 750mm 6hi CRM AGC

2017 750mm 6hi CRM AGC

-

TL No.84 Used 1250mm Tension Leveler

TL No.84 Used 1250mm Tension Leveler

-

2006 Wuxi Jinjie 250mm 4hi CRM

2006 Wuxi Jinjie 250mm 4hi CRM

-

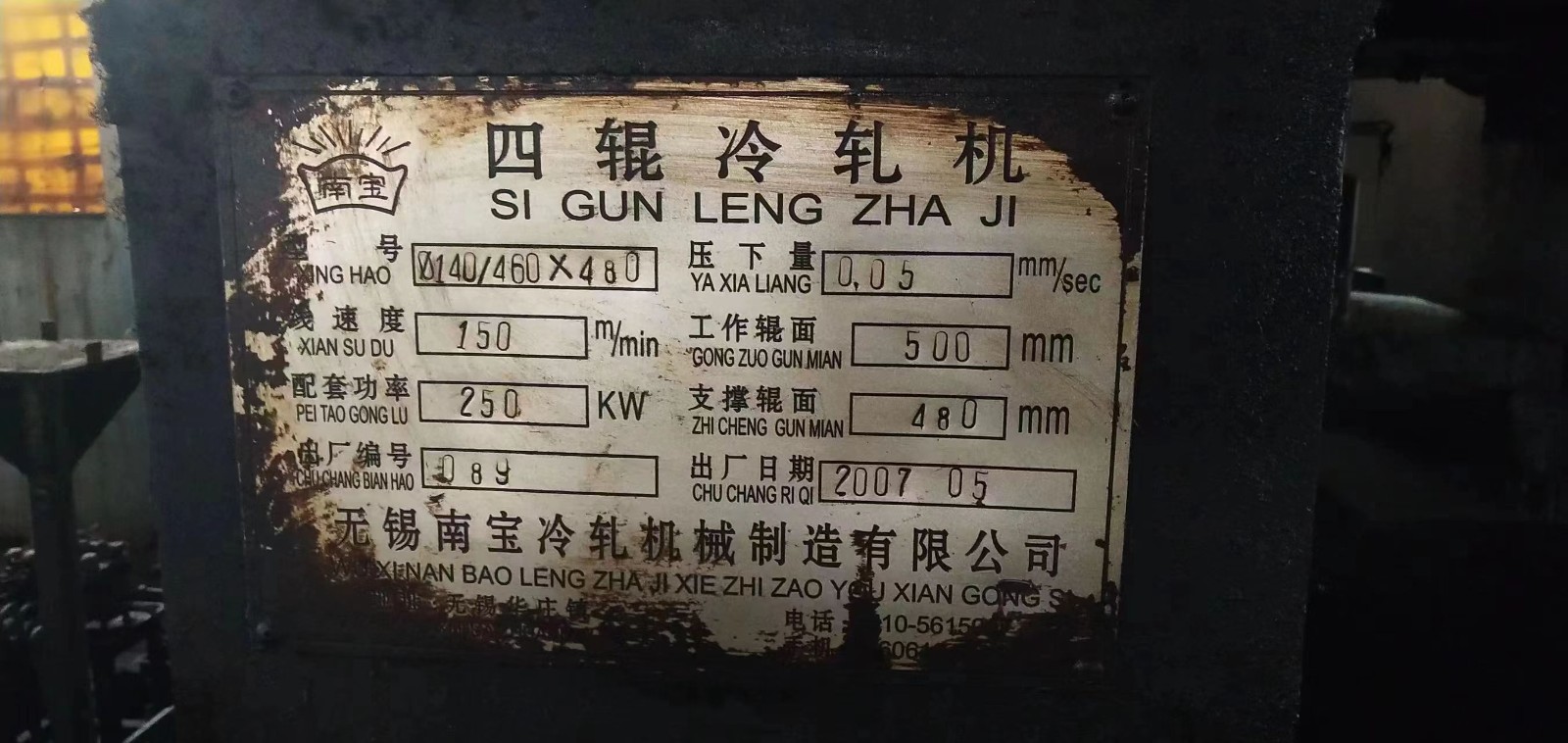

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

-

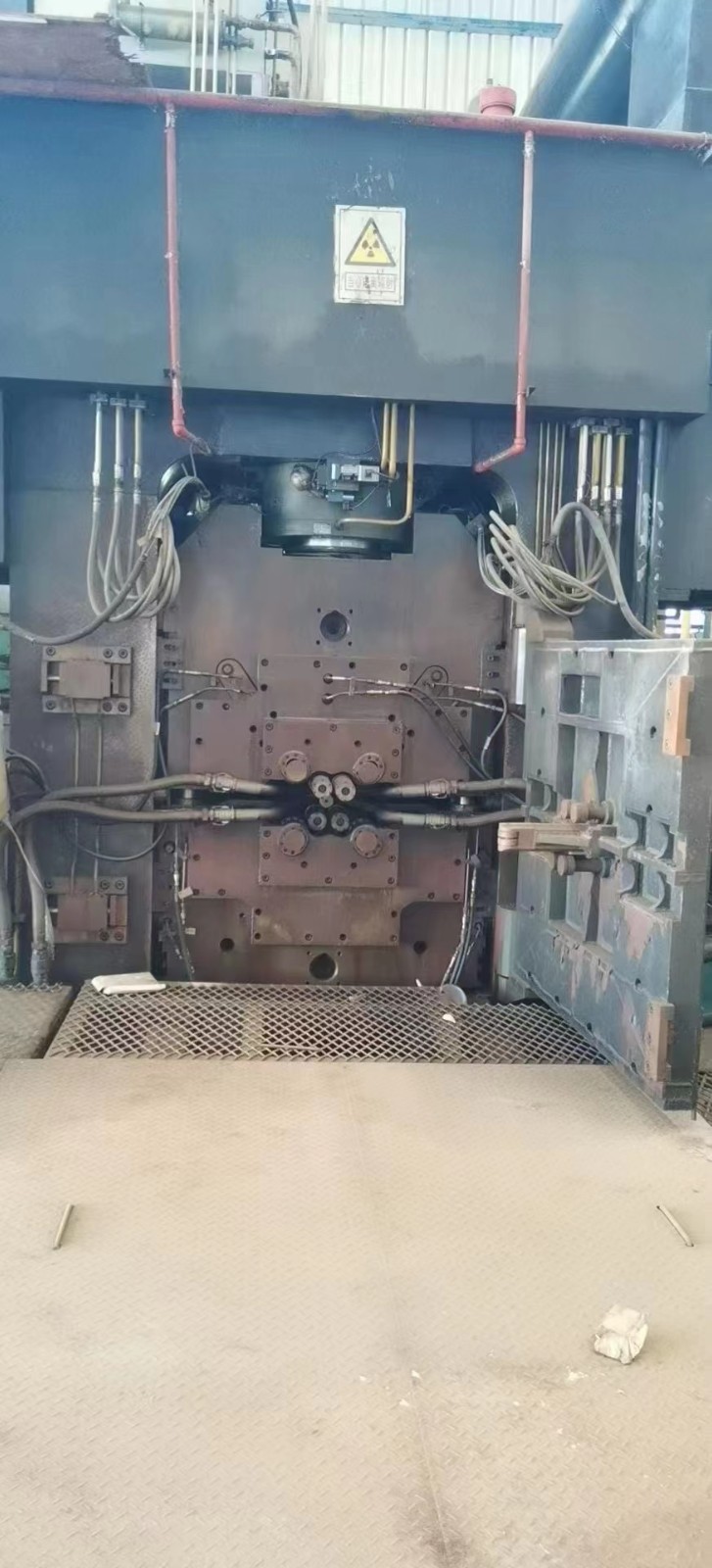

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

2008 TMEDI 1250mm 20hi CRM Stainless Steel

2008 TMEDI 1250mm 20hi CRM Stainless Steel

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

used 600mm 20Hi cold rolling mill

used 600mm 20Hi cold rolling mill

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

-

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

-

No.185 Used 1300mm aluminum cold rolling mill

No.185 Used 1300mm aluminum cold rolling mill

-

2008 Shanghai Machine Tool OD1250mm Roll Grinder

2008 Shanghai Machine Tool OD1250mm Roll Grinder

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

-

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

480mm cold rolling mill

480mm cold rolling mill

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

Mitsubishi 1050mm Tin plate cold rolling mill

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

-

2005 Chinese brand 550mm 4hi cold rolling mill

2005 Chinese brand 550mm 4hi cold rolling mill

-

1300mm tesion leveler aluminum

1300mm tesion leveler aluminum