Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

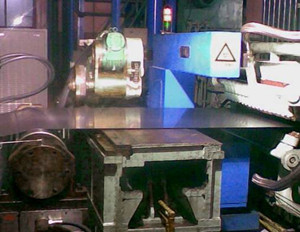

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

It is made in 2007--2008. The written time is April 25,2021- product description

- Technical Parameters

Technical parameters:

• Working roll size: ф 63.5× 1400mm material: cr12mnvco

• First intermediate roll size: ф 175 × 1420 mm material: 9Cr2Mo

• Second intermediate roll size: ф102 × 1580 mm material: 9Cr2Mo

• • Backing bearing roll: ф 300 × 160 of 24

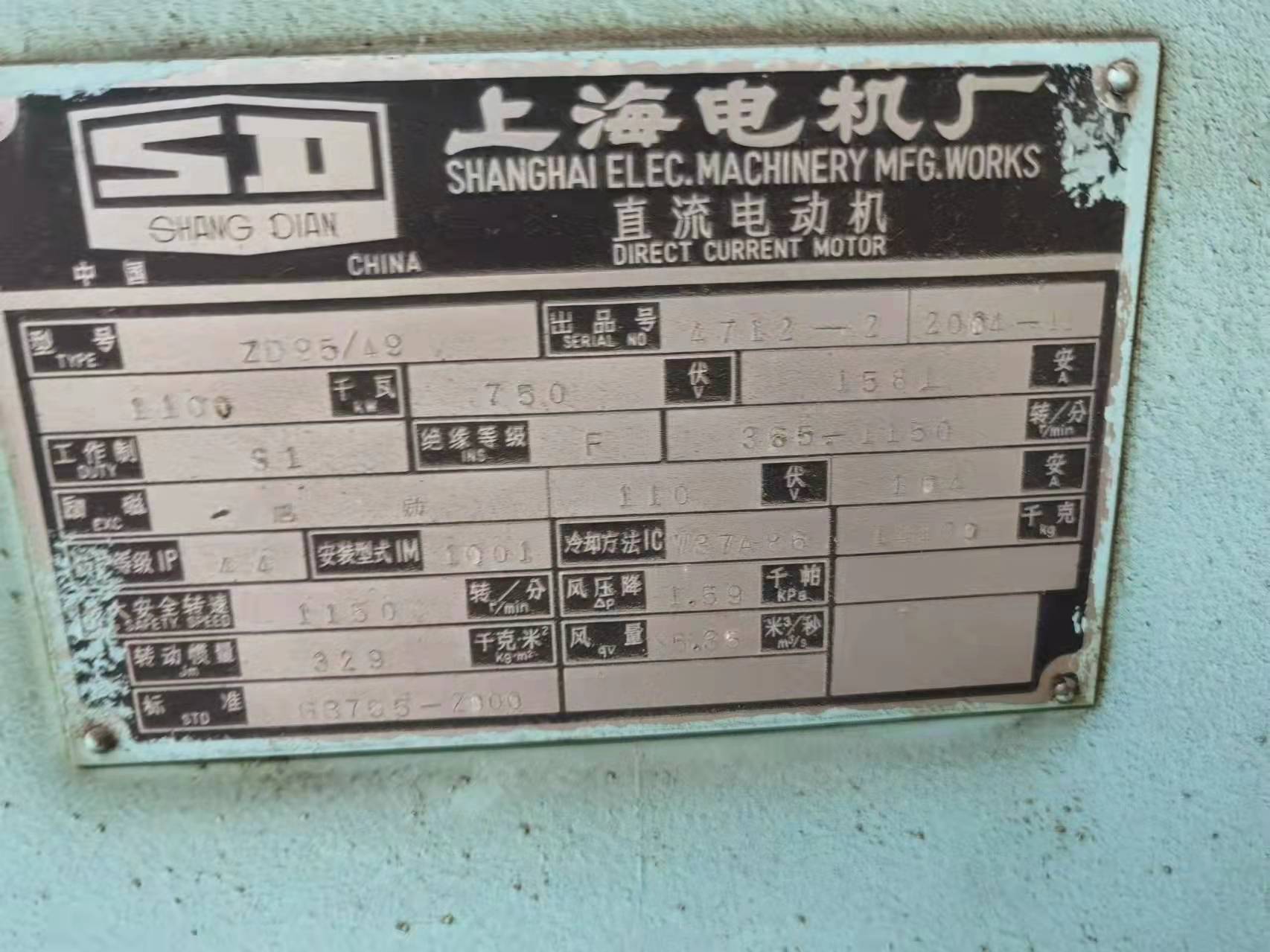

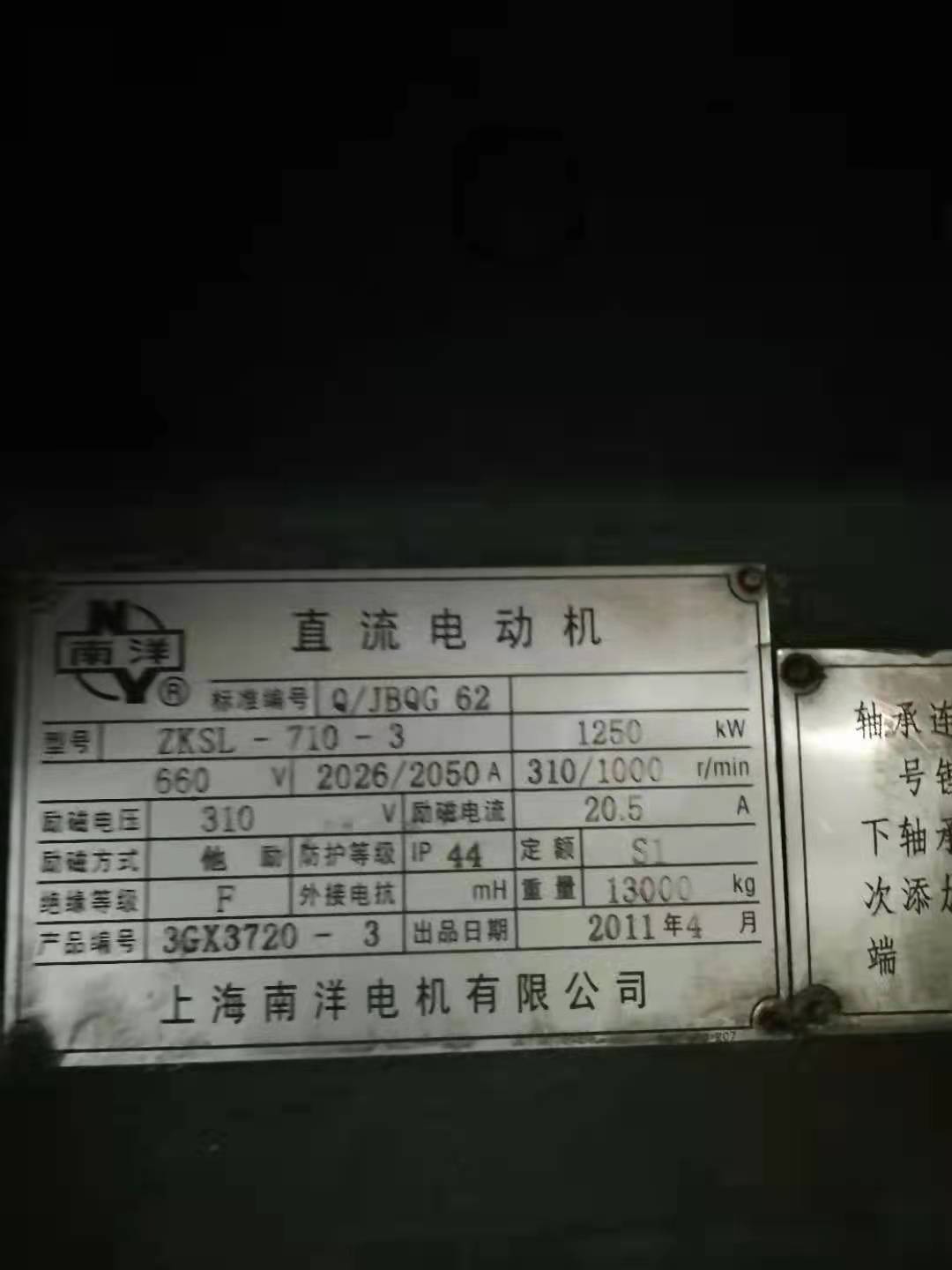

• Main rolling mill motor power: 2000 kW 660 V 500 ~ 1000 rpm

• Coiler power: 1500 kW 660 V 350 ~ 1000 rpm

• Maximum rolling pressure: 10000 kn

• Rolling speed: V ≤ 300 m / min

• Speed accuracy: steady state: ± 0.1%

• Maximum acceleration: 0.4m/s ² • Maximum deceleration of emergency stop: 1.5m/s ² • Fast stop deceleration: 1.0m/s ² • Normal parking deceleration: 0.2m/s ²

• Uncoiling tension: 60 kn

• Uncoiling speed: 90 m / min

• Drum diameter: drum Φ 585~ Φ 610mm

• Uncoiler motor: 250KW

Thickness of steel plate: 2.0 ~ 3.0 mm

Width of steel plate: 900 ~ 1250mm

Coil weight: 12 ~ 22.5 t

Material: stainless steel

Coil outer diameter: Ф 1800mm(max)

Inside coil: pickling plate Ф 610 mm

Tolerance requirements of hot rolled billet: longitudinal thickness difference ≤ 3%, transverse thickness difference ≤ 1.5%

How many process | Roll Thickness (mm) | Absolute pressure (mm) | Run down rate % | Under the total pressure ratio % | The total tension KN | roll speed M/min | roll pressure (T) | roll time(mins) | ||

post tension | pre-tension | continue roll | interbal roll | |||||||

0 | 2.75 | 2 | ||||||||

1 | 2.00 | 0.75 | 27.3 | 27.3 | 40 | 550 | 150 | 402 | 10.0 | 3 |

2 | 1.25 | 0.75 | 37.5 | 54.5 | 500 | 350 | 150 | 445 | 10.0 | 1 |

3 | 0.78 | 0.47 | 37.6 | 71.6 | 330 | 250 | 180 | 441 | 12.8 | 3 |

1 | 0.5 | 0.27 | 35.89 | 81.8 | 180 | 220 | 200 | 373 | 16.2 | 2 |

2 | 0.32 | 0.18 | 36 | 88.4 | 130 | 150 | 240 | 332 | 21.0 | 1 |

3 | 0.25 | 0.07 | 21.8 | 90.9 | 100 | 80 | 260 | 300 | 25.0 | 3 |

Scope of supply:

1. Two coilers and one uncoiler

2. Coil storage saddle of decoiler (two coils can be stored)

3. Winding car (hydraulic drive lifting and moving) and accessories

4. Uncoiling guide and uncoiling knife

5. Pinch roll and straightener

6. Bridge guide platform

10. Guide table and guide roll of entrance coiler

11. Entrance tension measuring guide roll

12. Entrance shear

13. Entrance three roll side guide alignment

14. Inlet degreaser (squeezing roller)

15. 20 high reversing rolling mill (including equipment in stand, excluding backing bearing of rolling mill)

16. Outlet degreaser (squeezing roller)

17. Exit shear

18. Exit tension measuring guide roll

19. Guide table and guide roll of exit coiler

24. Work roll change trolley (semi-automatic form), backup roll change trolley

25. The coupling of Uncoiler and drive motor, the coupling of inlet and outlet coiler and drive motor with brake disc.

26. Hydraulic system (one set of high pressure system and one set of low pressure system)

27. Two Isotope Thickness Gauges

28. Emulsion system

29. Thin oil lubrication system

30. Exhaust system of rolling mill

31. All backing bearings

32. Electrical and automatic control system

33. All DC motors

If you want to quote or further information on this product, please fill out the form below.

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

2011 Chinese Brand 1250mm 20hi CRM

2011 Chinese Brand 1250mm 20hi CRM

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

2010 used 1280mm 4hi one direction cold rolling mill aluminum foil

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

Mitsubishi 1050mm Tin plate cold rolling mill