Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

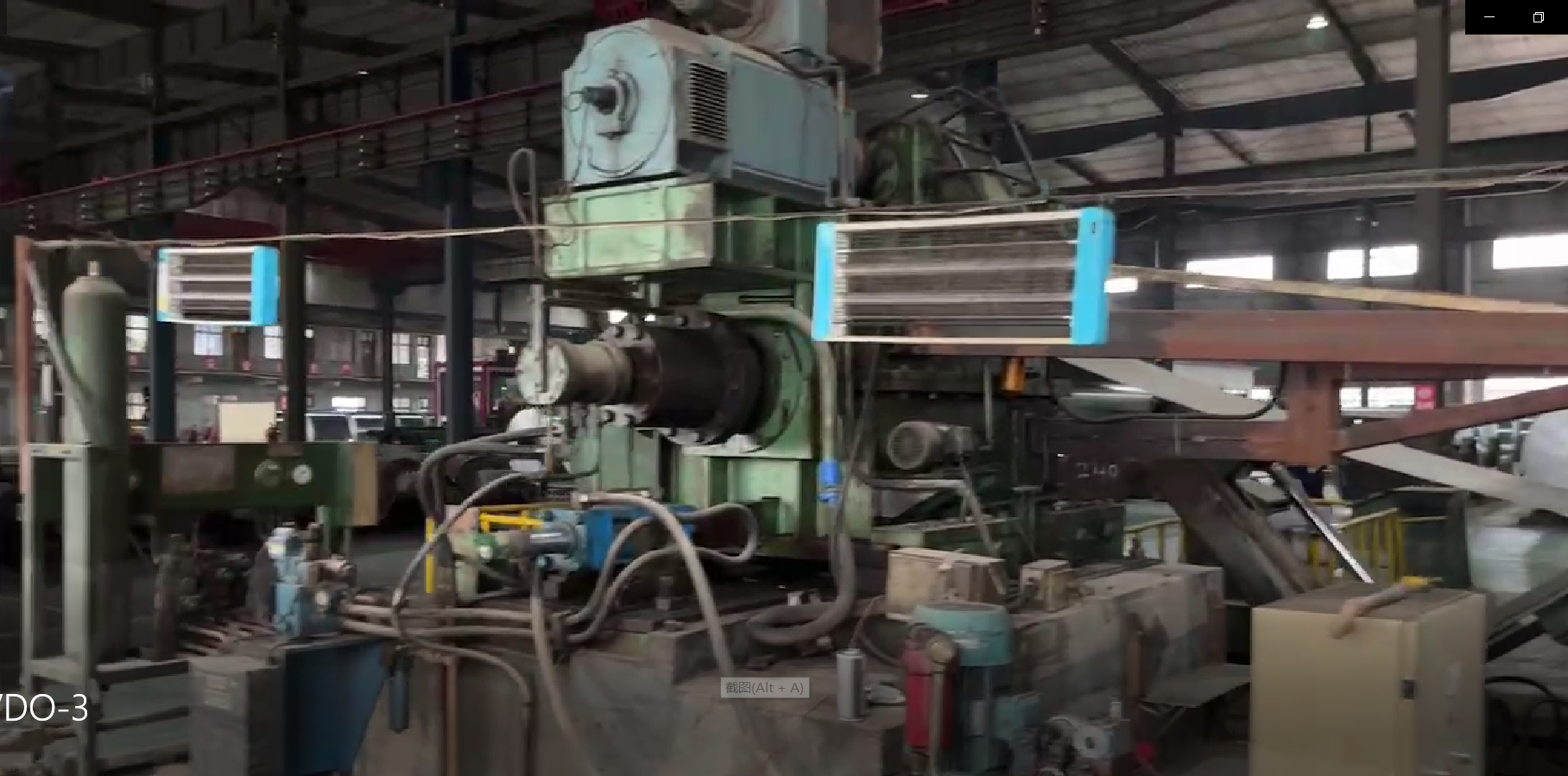

used cold rolling mill

2017 750mm 6hi CRM AGC

stock No.: 200, it is written on May 4, 2022- product description

- Technical Parameters

Technical specifications of complete equipment

machine is made in 2017, total weight approximate 350ton, spare parts approximate 50ton

material: carbon steel, stainless steel

catalogue

Annex 2.1 technical specifications of mechanical equipment

Annex 2.2 hydraulic and thin oil lubrication system

Annex 2.3 rolling oil system

Annex 2.4 technical specifications for electrical equipment

2.1 Mechanical equipment manual

2.1.1 Left (right) coiler

Function: roll the rolled strip steel into steel coil as required, and provide front and rear tension for the unit.

Structure: the coiler is composed of drum, drum drive device, push plate device, floating base, fixed base, etc. The pyramid of the drum is an integral structure, and the drum is of the expansion and contraction type of four sector plates. The expansion and contraction of the drum is completed through the expansion and contraction oil cylinder, with jaws. The drum is installed on the hollow shaft of the big gear in the reduction box and driven by a DC motor through the reducer. The rotary joint of the expansion and contraction oil cylinder is fixed on the box seat of the reducer and does not rotate with the drum. The gears and bearings in the reduction box are lubricated by centralized circulating oil supply from the built-in thin oil lubrication station. The base is welded with steel plate and fixed on the foundation.

The push plate is welded by thick steel plate. The push plate is fixed on the upper box of the coiler through two guide columns, and the forward and backward movement of the push plate is realized by turning the oil cylinder closed on the upper box.

Main parameters and performance:

Max. coil OD: φ1800mm

Min. coil OD: φ900mm

Coil width: 485 ~ 750mm

Coil weight: max.12000kg

Coiling direction: down coiling

Drum diameter: φ508mm

Effective length of drum: 850mm

Expansion and contraction range:φ480~φ508mm (secondary)φ520mm)

Specification of expansion and contraction cylinder: 1 set, 350 / 120, stroke 85.082 mm

Push plate cylinder: 1, 80 / 45, stroke 900 mm

Sector plate material: 42CrMo

Surface hardness of sector plate: hrc50-55

Spindle material: 42CrMo

Gear face of reducer: hard tooth surface

Gear material: 17Cr2Ni2Mo

Gear accuracy: Grade 6

Coiling tension: max.250 kn

Coiling speed: max.600 m/min

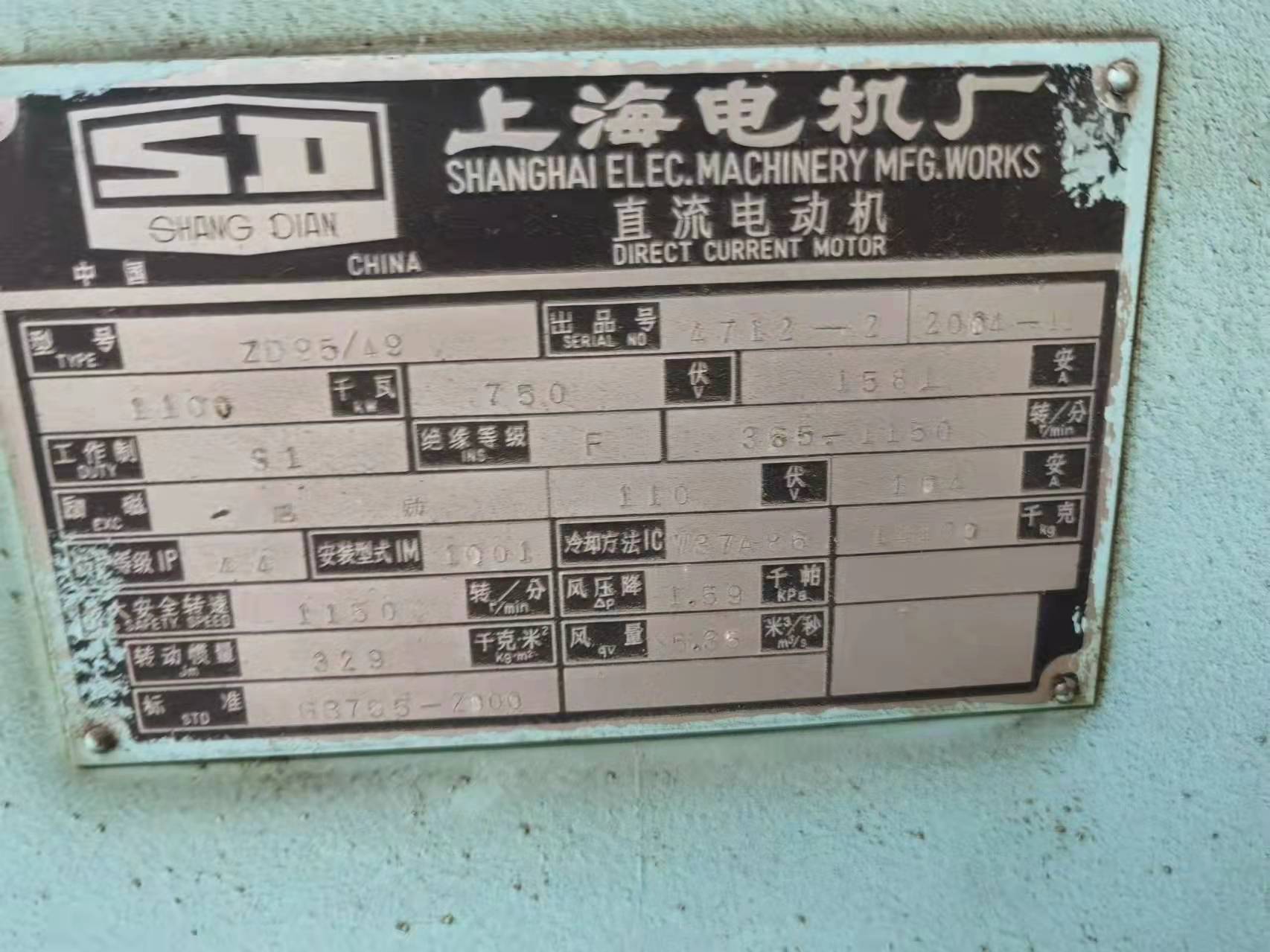

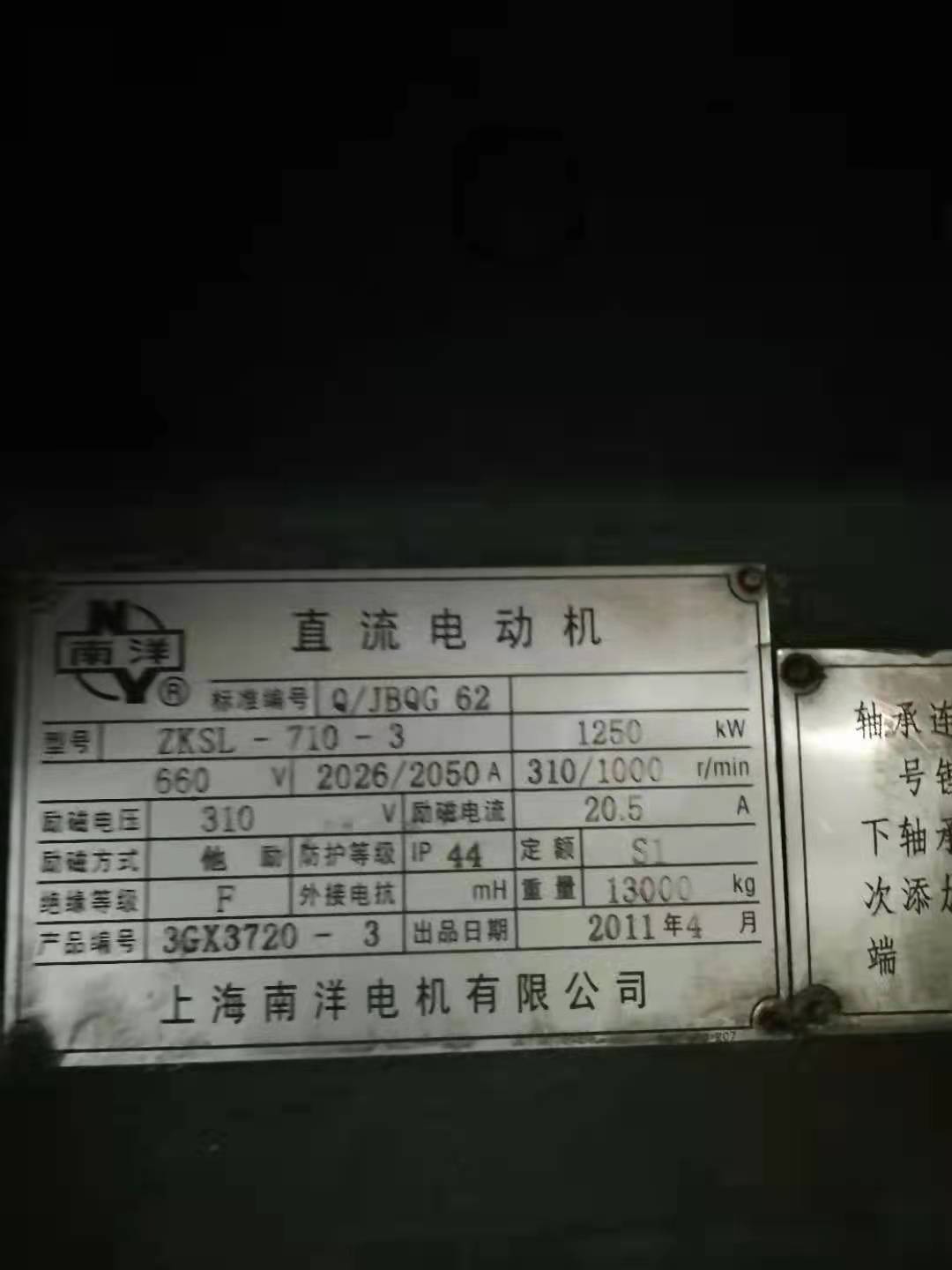

Drum drive motor: 1 set, power 1500kW, DC motor

Braking mode: pneumatic disc

Thin oil lubricating oil pump: 1 set / set, power 1.1kw

2.1.2Press roller (2 sets in total)

Function: the device is set on the coiler, pressing the strip steel and participating in the auxiliary belt threading.

Structure: it is composed of roller holder, cylinder, roller, etc.

Main technical performance:

Rollerφ200×600mm, 1 (polyurethane lined)

Lift cylinder 1

Specifications: Φ63/45

Stroke: ~400mm

2.1.3Left (right) process platform

Function: measure the thickness and speed of steel strip, so as to preset and feedback control the rolling mill.

Structure: the process platform is composed of base, clamping and steering device, shear, thickness gauge, oil removal device and side guide device.

The base of the process platform is made of structural steel and steel plate.The side is bolted to the lower part of the mill, and the bottom is fixed on the foundation with anchor bolts.

The clamping steering device is composed of pinch roll, clamping roll synchronization mechanism, steering roller, frame, lifting guide plate, etc.The pinch roller is a passive roller, which is driven by the cylinder to lift.The steering roller is an active roller, fixed on the frame and driven by a frequency conversion motor.The other end of the driving roller is equipped with a double encoder.

The shear machine is composed of fixed base, lower beam, upper tool frame beam, lower tool frame beam, blade, guide post, hydraulic cylinder, etc.The fixing seat is made of steel plate welding and installed on the base.The lower tool frame beam is made of steel plate welding, the bottom surface contacts the fixed seat, and the side can slide in the c-groove of the fixed seat.The hydraulic cylinder is installed on the lower cross member and the lower tool frame beam respectively.The lower beam, upper tool frame beam and lower tool frame beam are all movable and connected together through guide post.When shearing, the lower beam and upper tool frame beam move downward under the self weight and the reaction force of hydraulic cylinder;When the upper tool rest beam is in contact with the fixed seat, the lower tool rest beam moves upward under the force of the hydraulic cylinder to realize shearing.

The thickness gauge is X-ray thickness gauge with protective cover, which can be moved outside the line through hydraulic cylinder.

The degreasing device is composed of frame, degreasing roller, track, etc.The frame is made of steel plate welding.4 oil removal rollers, 2 upper rollers and 2 lower rollers have a deviation of 20mm from the center line. The lower roller can be adjusted manually, and the upper roller is driven by hydraulic cylinder to lift.One hydraulic cylinder is installed on the frame, which can pull the oil roller device out of the line.

The side guide device is composed of left and right sliding seat, screw, guide seat, vertical roller and hydraulic motor.When the hydraulic motor installed on one side drives the same side vertical roller to move, the vertical roller drives the screw rod fixed on it to move, so that two sets of symmetrical vertical rollers move symmetrically with respect to the center line of the unit, so as to achieve the purpose of alignment.

Main technical performance:

Pinch roll:Φ200x850 mm, (lined with nitrile rubber 15mm)

Steering roller:Φ300x850 mm

Material: 42CrMo, forging, surface quenching.

Degreasing roller:Φ200x850 mm (hollow)

Material: 20CrNi2Mo, surface quenching.

Vertical roller: 4,Φ100×200mm

Opening adjustment: 500-850mm

Centering hydraulic motor: 1

Model: bmr-80p1a1y1

Blade specification: 20×100×1000mm

Blade material: Cr12MoV

Cutting edge opening: ~ 200mm

Pinch roll oil cylinder: 2

Specifications:Φ50/28

Stroke: ~ 150mm

Guide cylinder: 1

Specifications:Φ80/45

Stroke: ~650mm

Shear cylinder: 2

Specifications:Φ125/63

Stroke: ~ 250mm

Lifting oil cylinder of degreasing roll: 4

Specifications:Φ80/45

Stroke: ~190mm

Oil removal device pull out cylinder: 1

Specifications:Φ80/45

Travel: ~1200mm

Steering roller motor: 22KW, 750rpm

Thickness gauge: 1 set

2.1.4 Main body of rolling mill

1) Functions

The main body of the rolling mill is a six high cold rolling mill, which is used for rolling the hot rolling or strip stripping after pickling at normal temperature

Steel, after one pass of rolling.The mill adopts the intermediate roll transmission, and the main motor drives the upper and lower intermediate roll of the rolling mill through the coupling, reducer and universal joint shaft respectively, and then drives the working roll to roll the strip.The rolling mill can adjust the relative position of the intermediate roll according to different strip width, and adjust the bending force in the rolling process to ensure the strip shape is good.The wedge device compensates for the change of the roll diameter.

2) Equipment composition:

The 850mm 6 hi rolling mill consists of frame assembly, roller system assembly, pressure down cylinder, rolling line adjustment device, intermediate roll traverse device, support roll balance device, emulsion injection system, shaft connecting bracket, main drive device, smoke exhaust system and equipment upper piping.

(a) Rack assembly

It is composed of rail base, archway, upper and lower beams, intermediate roll bending roller block, inner guide rail, working roll lock plate, support roller lock plate, support roller pressing device, shaft connecting clamp device, etc.

Rail seat

Two pieces in total, steel castings, supporting the archway under the archway

Stand

The two pieces are steel castings (zg270-500), and the columns are machined on all sides;The inner lining of the archway window is wear-resistant plate, which is installed on the archway with screws.After casting, the internal stress can be eliminated by aging treatment.And ultrasonic inspection shall be conducted.

Upper beam

The upper beam is a welding part to connect two archways.

Intermediate roll bending block

For embedded bending block, it is embedded in the cylinder block, and the cylinder block is combined on the archway window, and two on the transmission side and operation side. Each bending cylinder block has two bending cylinders. The piston type cylinder rod head is designed to be T-shaped structure, which is matched with the T-groove of the bearing seat of the intermediate roller to realize the positive and negative bending functions of the intermediate roll.The cylinder seals are all imported seals.

Guide rail in the machine

All are forged steel parts, which are set in the rolling mill window, which are composed of the upper and lower working roll tracks, upper and lower intermediate roll tracks and lower supporting roller tracks.The rails of the upper work roll and the upper intermediate roll are floating structures, and their lifting cylinders are respectively arranged on the work roll cylinder block and the intermediate roll channeling cylinder block, and their cylinder seals are imported seals.When changing rollers, the rollers move on their own tracks.

Work roll lock plate

It is installed on the cylinder block on the operation side and is a movable chuck driven by the hydraulic cylinder (the hydraulic cylinder is installed on the frame on the operation side). The movable chuck shared by the upper and lower work rolls is used to compress the work rolls axially.

Backup roll locking device

On the frame on the operation side, the movable clamping plate driven by the hydraulic cylinder (the upper and lower backup rollers are separate) compresses the backup rollers axially.

Connecting shaft bracket device

When changing the roll, connect the shaft bracket universal coupling, which is composed of supporting plate, bracket, fixing block, hydraulic cylinder, etc.

(b) Roll system assembly

The work roll, intermediate roll and backup roll are equipped with corresponding special rolling bearings for four row short cylindrical rolling mill and corresponding oil mist lubrication piping.

Work roll assembly

The bearing pedestal is made of forged steel (42CrMo), with end cover, distance ring and seal. The upper part of the upper bearing pedestal and the bottom of the lower bearing pedestal are equipped with wheels, and sliding plates are equipped on both sides. The sliding plates are aluminum bronze alloy with high wear resistance, and the wheels are used for roll change.The bearing pedestal is designed to meet the requirements of rapid roll change.

Intermediate roll assembly

The bearing pedestal is made of forged steel (42CrMo) with sliding plate. The sliding plate is aluminum bronze alloy with high wear resistance, with end cover, distance ring and seal. The upper part of the upper bearing pedestal and the bottom of the lower bearing pedestal are equipped with wheels for roll change.There are wings on both sides of the bearing seat for intermediate roll bending. The design of the bearing seat meets the requirements of rapid roll change.

Backup roll assembly

The bearing pedestal is made of steel casting (ZG42CrMo) with sliding plate. The sliding plate is aluminum bronze alloy with high wear resistance, with end cover, distance ring and seal.There are wheels on the bearing seats on the operation side and transmission side of the lower backup roll, which is convenient to move when changing the roll.

(c) Intermediate roll traverse mechanism

It is composed of upper and lower intermediate roll positive bending cylinder block, hydraulic cylinder roll shifting device, connecting beam, intermediate roll clamping device, etc.The connecting beam connects the roll bending cylinder blocks on the operation side and the transmission side into one, the upper and lower roll bending beams are connected into one on the transmission side respectively, and are connected with the corresponding intermediate roll bearing seat in a clamp, and push and pull the roll bending beam to drive the transverse movement of the intermediate roll and realize the positive roll bending of the intermediate roll through four transverse cylinders (with displacement sensor and locking with expansion sleeve) installed on the end face of the archway on the transmission side,In order to obtain the best roll shape adjustment effect.The sealing of roll bending oil cylinder is inlet sealing.

(d) Elevation adjusting device of rolling line

The rolling line elevation adjustment device is composed of a set of inclined wedges and step base plates installed on the upper part of the archway to steplessly adjust the rolling line elevation.Adjust the built-in linear displacement sensor of the oil cylinder.

(e) Backup roll balancing device

The backup roll balancing device is located on the top of the rolling mill and is composed of a balancing oil cylinder, a guide rod, a beam, etc. the cylinder seat of the balancing oil cylinder is closed on the top of the archway and the guide rod is lifted and lowered through the reaction force, so as to realize the balance and positioning of the upper backup roll.

(f) emulsion nozzle device

The nozzle device is located at the inlet and outlet of the rolling mill. The inlet and outlet are symmetrically arranged. During rolling, the roll is cooled and the steel plate and roll surface are lubricated.

Each side of the roll is composed of two spray beams (two above and below the strip steel) and five rows of nozzles.There is one spray beam for the upper and lower work rolls, and two rows of nozzles are set on each spray beam to spray the work roll body and roll gap.The nozzle on the spray beam is controlled in three sections along the width direction.Upper intermediate roll and backup roll roll gap, 1 jet beam, single row nozzle.

Four spray beams are set on the upper and lower transverse moving beams to lubricate the upper and lower parts of the inlet strip.

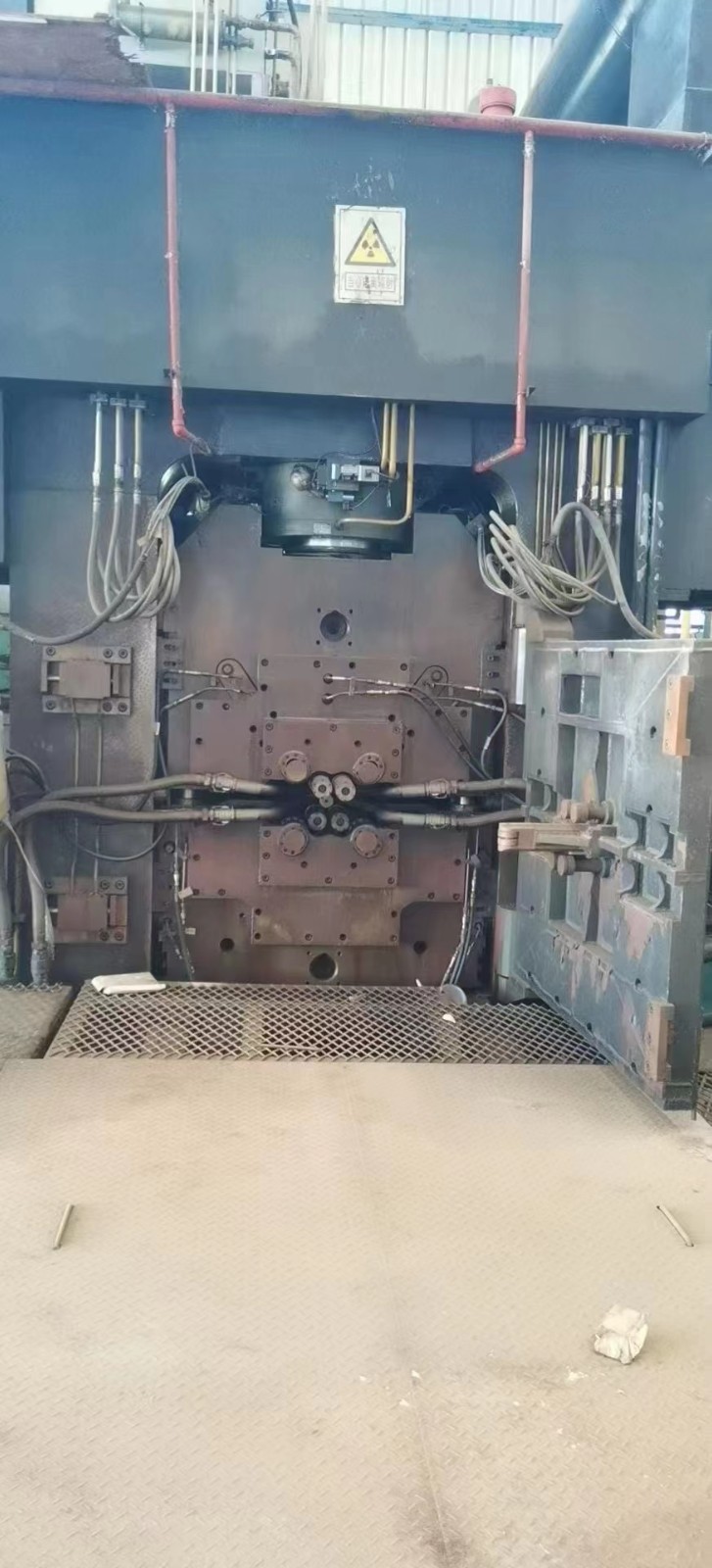

(g) AGC upper cylinder

Located below the frame window, the press up cylinder is the actuator of the press down control of the rolling mill. It is characterized by large structural stiffness, low friction coefficient and good sealing performance, so as to ensure that the overall system has high response characteristics.Ensure that the oil cylinder has high position resolution accuracy during operation. Therefore, the oil cylinder is made of alloy steel and processed by special design and processing technology to meet the above requirements.Press on oil cylinder with high-precision MTS magnetic ruler displacement sensor.

(h) Transmission device

The transmission device is composed of combined reducer, connecting shaft, connecting shaft bracket, safety coupling, main motor, etc.

The combined reducer includes the upper and lower layers of gear reduction and gear base. The upper and lower intermediate rollers are driven by DC motor for rolling.The reducer adopts hard tooth surface grinding, and the gear accuracy is grade 6-6-5 (gb10095-88).Centralized thin oil circulating lubrication of reduction gearbox.

The connecting shaft is located between the reducer and the intermediate roll and is used to transfer the rolling torque.The shaft connecting bracket is used to support the shaft in the middle of the shaft when changing the roll and balance the weight of the shaft.The safety coupling is located between the motor and the reducer to transmit the motor torque and protect the motor (cut off the safety pin in case of abnormal working conditions such as belt breaking).

(i) Walkway, smoke exhaust hood, rolling shutter door and frame closure

It is composed of walking platform, ladder, on-board platform, platform coaming, left and right smoke exhaust hood, electric rolling shutter door, etc.

It mainly provides convenient access for the maintenance of the equipment above the rolling mill, and sucks the rolling oil fume and hot gas.It is located in the front and upper part of the frame and is sealed around to prevent emulsion splashing and smoke drifting.The frame is closed by steel frame welding structure, and the outer lining is closed by panel.A platform with steel skeleton welding structure is formed on the top of the rolling mill, and the platform is equipped with a closed type.

(j) On board piping

It is used for the connection of mechanical equipment and fluid equipment.It mainly includes emulsion pipeline, hydraulic pipeline, pneumatic system pipeline and oil-gas lubrication piping.

3) Technical parameters

Maximum rolling pressure of stand: 10000kN (21MPa)

Rolling speed

Rolling speed of rolling mill: maximum 600m / min

Acceleration / deceleration: maximum 30m / min / S

Rolling elevation: + 1160mm

Stand column section: 480×560=268,800mm2

Work roll size:Φ170/Φ150×850mm

Maximum opening of work roll: 30mm

Intermediate roll size:Φ295/Φ275×850mm

Positive / negative bending force of intermediate roll: + 100 / - 80KN (each bearing seat)

Backup roll size:Φ780/Φ730×800mm

Balance force of backup roll: 200kn (per roll)

Press on the cylinder:Φ540/Φ460×125mm

Auxiliary hydraulic system pressure: 14 MPa

High pressure system pressure: 25 MPa

Cooling medium: emulsion

Process lubrication flow: 3000L / min

Main rolling mill motor: 1250KW, 660V

If you want to quote or further information on this product, please fill out the form below.

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

2008 Shanghai Machine Tool OD1250mm Roll Grinder

2008 Shanghai Machine Tool OD1250mm Roll Grinder

-

TL No.84 Used 1250mm Tension Leveler

TL No.84 Used 1250mm Tension Leveler

-

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

2009 Hubei Jiangzhong Machinery 1250mm 8hi 5 stands TANDEM CRM

-

used aluminun tension leveler line

used aluminun tension leveler line

-

2007 Chinese brand 700mm 4hi stainless steel CRM

2007 Chinese brand 700mm 4hi stainless steel CRM

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

2018 Wuxi 700mm 4hi reverse cold rolling mill AGC stainless steel

-

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

CR No.36 1350mm Aluminum Foil Cold Rolling Mill

-

2005 Chinese brand 550mm 4hi cold rolling mill

2005 Chinese brand 550mm 4hi cold rolling mill

-

used 600mm 20Hi cold rolling mill

used 600mm 20Hi cold rolling mill

-

1300mm tesion leveler aluminum

1300mm tesion leveler aluminum

-

2006 Wuxi Jinjie 250mm 4hi CRM

2006 Wuxi Jinjie 250mm 4hi CRM

-

2004 1700mm 4hi cold rolling mill IHI

2004 1700mm 4hi cold rolling mill IHI

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

2017 Wuxi Weisheng 630mm 4hi reverse cold rolling mill AGC

-

FIVES 20hi cold rolling mill

FIVES 20hi cold rolling mill

-

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

No.180 Used 1400mm 20 Hi single stand stainless steel reversible cold rolling mill

-

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

CR No.129 Used 1150mm 6Hi Cold Rolling Mill

-

CR No.24 Used Bell Furnace

CR No.24 Used Bell Furnace

-

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 ACHENBACH 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

CR No.9 Used Tippins 1550mm 4-hi reverse CRM

-

2006 China First Heavy 6hi 2 stand reverse CRM

2006 China First Heavy 6hi 2 stand reverse CRM

-

used 1250mm 6 hi reverse cold rolling mill

used 1250mm 6 hi reverse cold rolling mill

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

CR No.168 used 4hi reverse cold rolling mill

CR No.168 used 4hi reverse cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

CR No.37 1500mm Aluminum Cold Rolling Mill

CR No.37 1500mm Aluminum Cold Rolling Mill

-

No.185 Used 1300mm aluminum cold rolling mill

No.185 Used 1300mm aluminum cold rolling mill

-

Dec. 2007 Chinese brand OD1250mm roll grinder

Dec. 2007 Chinese brand OD1250mm roll grinder

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

Mitsubishi 1050mm Tin plate cold rolling mill

-

used 14hi cold rolling mill stainless steel

used 14hi cold rolling mill stainless steel

-

2012 650mm 4hi reverse cold rolling mill ss

2012 650mm 4hi reverse cold rolling mill ss

-

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

CR No.54 1750mm 4Hi Irreversible Aluminum Finishing Mill

-

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

CR No.131 1280mm Single zero Aluminum foil cold rolling mill

-

2006 MCC5 700mm 6hi cold rolling mill

2006 MCC5 700mm 6hi cold rolling mill

-

2011 1050mm 6hi reverse cold rolling mill

2011 1050mm 6hi reverse cold rolling mill

-

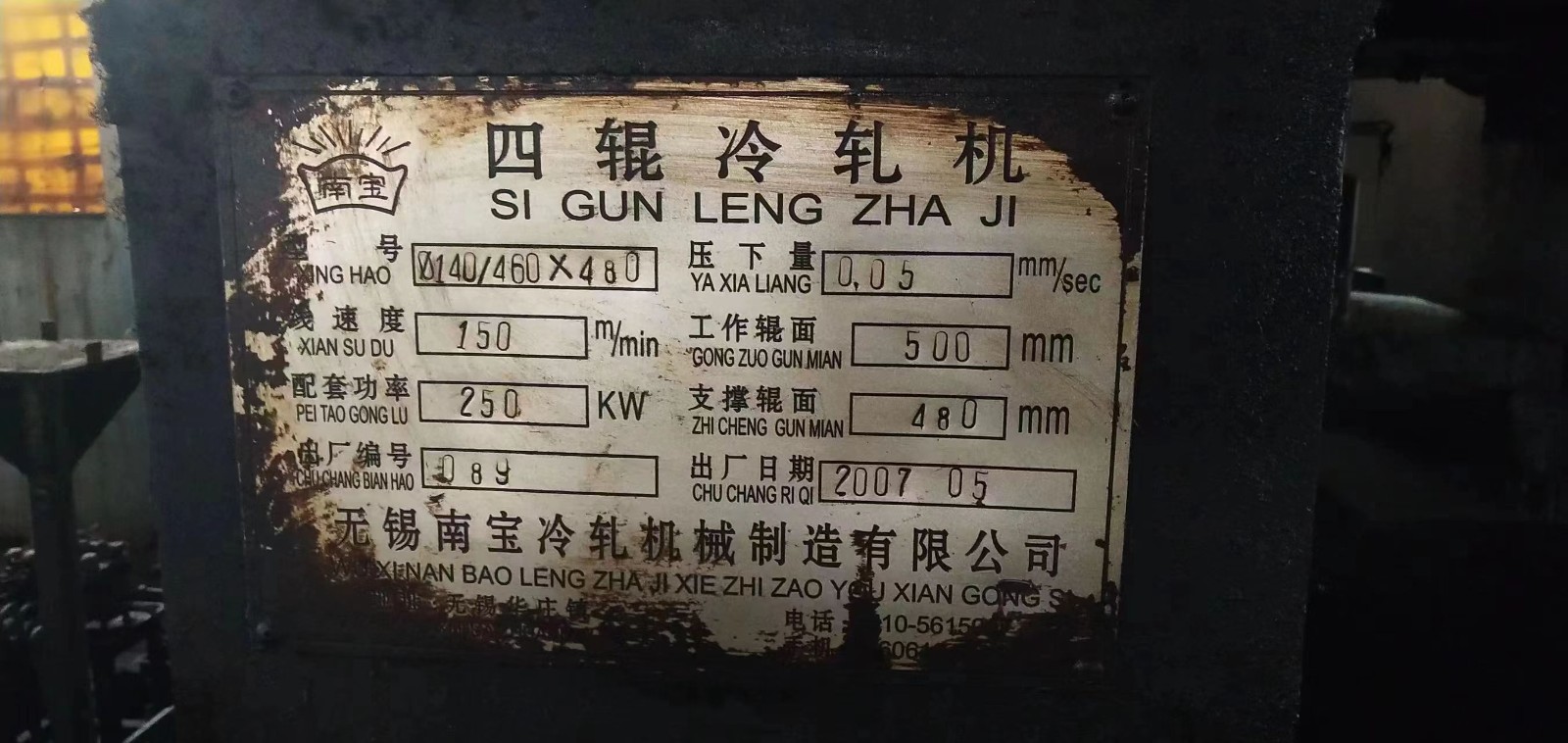

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

2007 Wuxi Nanbao 480mm 4hi Reverse CRM

-

2008 TMEDI 1250mm 20hi CRM Stainless Steel

2008 TMEDI 1250mm 20hi CRM Stainless Steel

-

2012 used 1250mm 6hi reverse cold rolling mill

2012 used 1250mm 6hi reverse cold rolling mill

-

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

CR No.69 Used 420mm 6 Hi Cold rolling mill AGC

-

2001 VOLLMER 900mm 20hi cold rolling mill copper

2001 VOLLMER 900mm 20hi cold rolling mill copper

-

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

2013 Wuhan Qianye 750mm 6hi Cold Rolling mill

-

480mm cold rolling mill

480mm cold rolling mill

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

2011 used 1600mm cold rolling mill aluminum

2011 used 1600mm cold rolling mill aluminum

-

2011 Chinese Brand 1250mm 20hi CRM

2011 Chinese Brand 1250mm 20hi CRM