Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

Cold Rolling Mill

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

stock No.:208, it is written on Jan.7,2022- product description

- Technical Parameters

1. Basic information

machine is made in 2007 by China 1st Heavy Machinery Factory

1300mm 6 hi reverse cold rolling mill is a hot-rolled coil made of ordinary carbon steel and low alloy high-quality steel with a thickness of 1.5~4.0mm after pickling and trimming, which is rolled for several passes at room temperature to make it into cold-rolled coils of various specifications with required thickness and surface roughness.

2. Main performance parameters of the unit

2.1 Raw material status: hot rolled steel coil after pickling (edge cutting or no edge cutting).

2.1. 1. Raw material: low carbon steel, medium carbon steel and low alloy steel.

Representative steel grades: Q195 ~ Q235, 08Al, 20#, SPCC, SPCD

2. 1. 2. Material properties: σb= 260~630 N/mm2

σs=140~450 N/mm2

2. 1. 3. Thickness: 1 .5~4. 0 mm

2. 1. 4. Width: 800~1300 mm

2. 1. 5 coil inner diameter: Φ 610 mm

2. 1. 6. Coil outer diameter: Φ 1100~ Φ 2100mm (equipment capacity)

2. 1. 7. Maximum coil weight: 28 t (equipment capacity, output calculation shall be based on the hot rolling coil weight proposed by Tanggang)

2.1. 8. The heating and rolling raw materials meet the national standards GB709-88, GB710-91 and GB912-89.

2. 1. 9. The steel strip halo (including thickness tolerance) shall comply with the dimensions, shape, weight and allowable deviation of GB708-88 cold rolled steel sheet and strip, GB13237-91 high quality carbon structure steel cold rolled sheet and strip, GB / T2520-2000 cold rolled galvanized tin sheet, GB / T5213-2001 cold rolled sheet and strip for deep drawing, GB / T11253-89 carbon structural steel and low alloy structural steel cold rolled sheet and strip.

2.2 finished products

2.2.1 thickness: 0.2~2mm (carbon steel and low alloy)

2.2.2 width: 900~1300 mm

2.2.3 coil inner diameter: Φ 610 mm

2.2.4 coil outer diameter: Φ 1100~Φ 2100mm

2. 2. 5. Maximum coil weight: 28 t (equipment capacity)

2.3 finished product accuracy:

See product assessment guarantee value.

2.4 main technical parameters of the unit:

2. 4. 1. Maximum rolling pressure: 20000 kN

2.4. 2. Maximum rolling torque: 150 kNm

2.4. 3. Maximum rolling speed: 900 m / min

2.4.4 threading speed: 60 m / min

2.4. 5. Maximum uncoiling speed: 400 m / min

2.4. 5. Maximum coiling speed: 960 M / min

2. 4. 6 uncoiling tension: 7~70 kN

2.4. 7. Coiling tension: 7~70 kN (single motor)

70~140 kN (double motor)

2. 4. 8 working roll size: Φ 425 / Φ 385X 1450mm

2.4. 9 intermediate roll size: Φ 490/ Φ 440X1480 mm

2.4. 10 backup roll size: Φ 1300/ Φ 1150X1450 mm

2. 4. 11 diameter of Uncoiler drum: (expansion / contraction): Φ 630 / Φ 570 mm (nominal Φ 610mm)

2.4. 12 coiler drum diameter: (expansion / contraction): Φ 610/ Φ 585 mm

2. 4. 13. Section of rack column: 600 x 800 = 480000mm2

2.4. 14. Minimum opening of work roll: 20mm

2.4. 15 positive / negative roll bending force of work roll (single roll one side): 360 / 180 kN

2.4. 16 positive bending force of intermediate roll (one side of single roll): 500 kN

2.4. 17 intermediate roll traverse: 325mm

2.4. 18 pressure of general hydraulic transmission system: 14 MPa

2. 4. 19 pressure of balance roll bending system: 28 MPa

2.4.20 holding down system pressure: 28 MPa

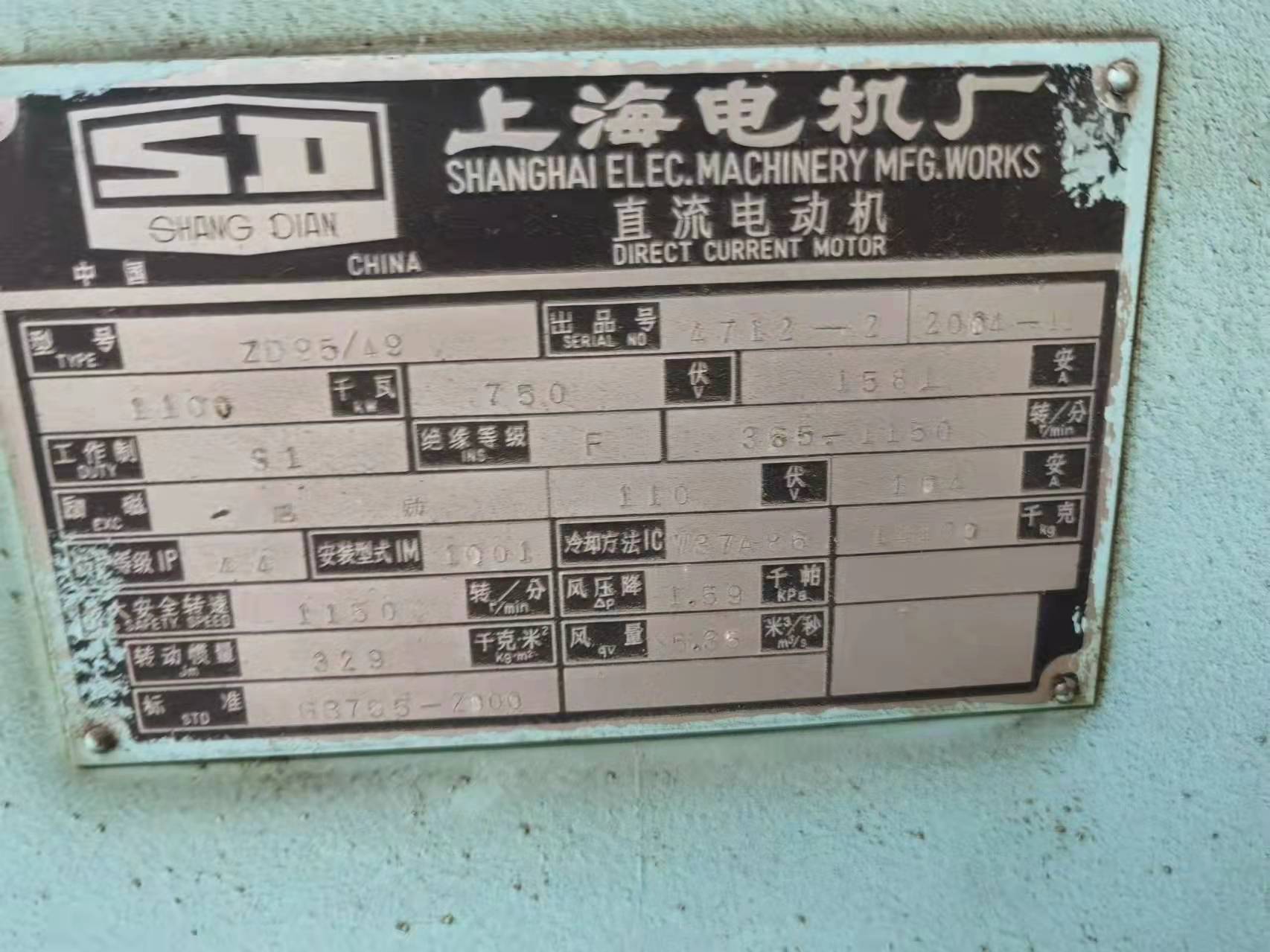

Main motor power

Main rolling mill motor: N = 1250kW, 4 sets in total

Left and right coiler motors: N = 1200kW DC motor, 2 each, 4 in total

Uncoiler motor: N = 500kW, 1 set in total

If you want to quote or further information on this product, please fill out the form below.

-

cold rolling mill working rolls

cold rolling mill working rolls

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

2011 used 1700mm cold rolling mill aluminum

2011 used 1700mm cold rolling mill aluminum

-

used 1250 4HI irreversible cold rolling mill aluminum

used 1250 4HI irreversible cold rolling mill aluminum

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

KOBELCO used cold rolling mill 1300mm Aluminum

KOBELCO used cold rolling mill 1300mm Aluminum

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

used Kobelco cold rolling mill aluminum 1300mm

used Kobelco cold rolling mill aluminum 1300mm

-

Used 1250 6hi reverse cold rolling mill in Shanghai, China

Used 1250 6hi reverse cold rolling mill in Shanghai, China

-

used tension leveler aluminum

used tension leveler aluminum

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

-

1250mm 6hi revisible cold rolling mill

1250mm 6hi revisible cold rolling mill

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil