Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

ERW Tube Mill

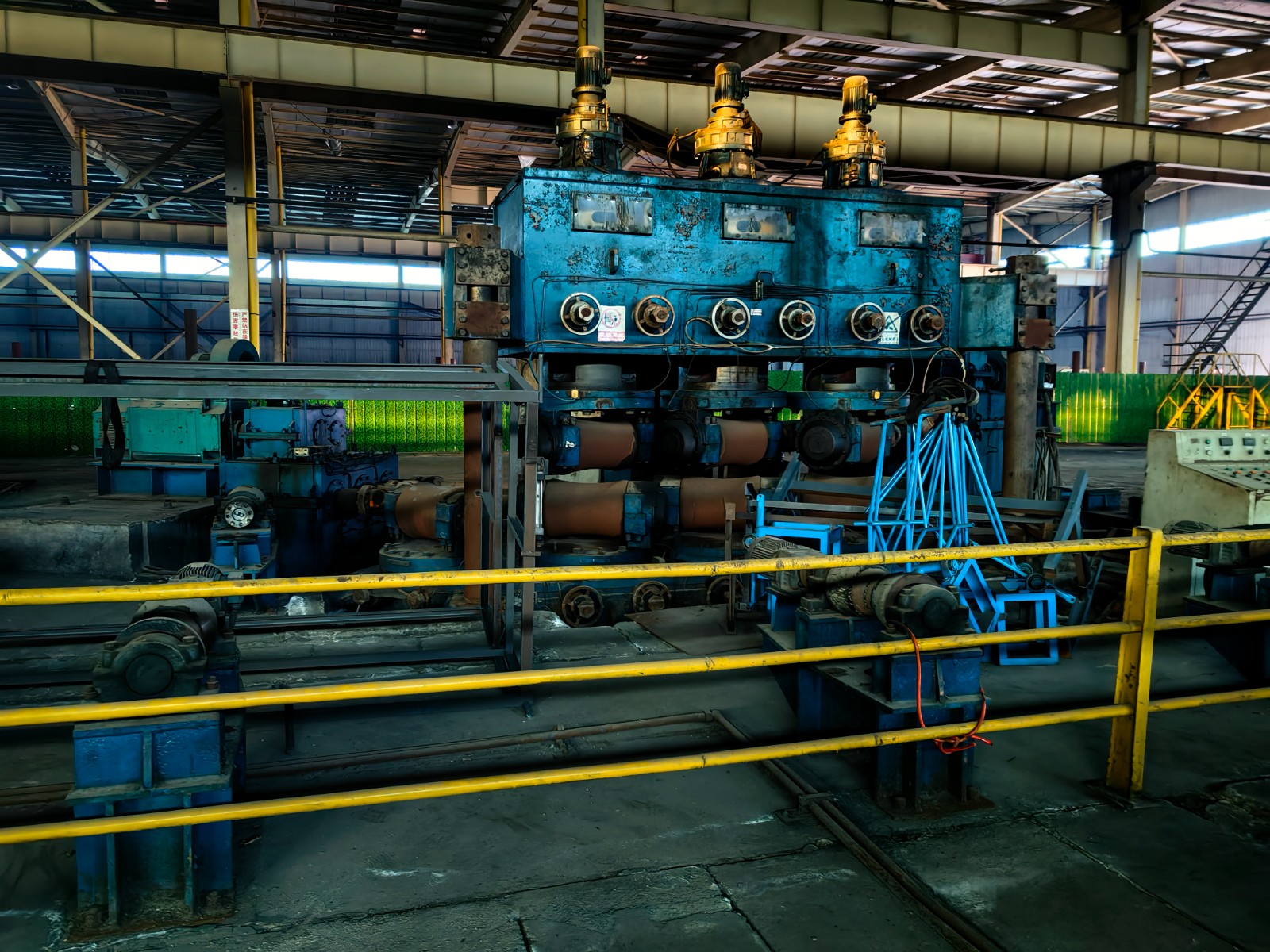

2019 Φ245×8mm ERW tubemill

it is written on November 16, 2022. Stock No.: 428.

- product description

- Technical Parameters

Pipe diameter: φ 89、 φ 114、 φ 168、 φ 219、 φ 245mm

Square tube specification: 120 ²、150 ²、200 ²

Wall thickness of round pipe: 3-8mm

Fixed length: 6~12m

The product complies with the national standard GB/T3091-2008 Welded Steel Tubes for Low Pressure Fluid Transport

2. Technical performance of the unit

2.1 Raw material: hot rolled strip coil or steel strip coil sheared longitudinally

Strip steel material: Q235, Q345B

Strip steel width: 250~800mm

Width tolerance: ± 0.5mm

Strip steel thickness: 3-8mm

Coil OD: Φ 1000~ Φ 1800mm

Coil ID: Φ 760mm

Coil weight: ≤ 15t

2.2 Main performance of the unit:

Molding method: F-F molding system bottom line positioning

Unit operation direction: right feeding (can be arranged according to site requirements)

Unit operation elevation:+900mm

Forming frame: 7 two roll frames; Three four roll racks;

Sizing rack: 4 universal racks, 2 first racks in Türkiye

Transmission mode: forming centralized transmission DC 2 × 132Kw

Calibrated centralized drive DC 1 × 160Kw

Forming welding speed: 10 ~ 40 m/min

Welding mode: solid high-frequency welding

Welding power: 600 KW (solid state high frequency)

Unit production capacity: 150000~200000 tons

2.3 Workshop conditions:

Floor area: ~ 24 × 280m

Power supply: 3-phase AC380V 50HZ

Control power supply: single-phase AC220V 50HZ

Compressed air flow: 5 m3/min

Pressure: 0.6118 Mpa (6kg)

Circulating water flow: 120 t/h

Pressure: 0.3 Mpa

Water quality: turbid circulating water (for cooling circulation)

Turbid circulating water storage: 100m3

Installed capacity of unit equipment: ~1400KW![]()

|

| |

3. Process flow:

coil car → uncoiler →coil opener → coil straightener→shear welder →horizontal accumulator → edge planing → FF rough forming → fine forming → high-frequency welding → external burr scraping → water cooling → sizing unit → Türkiye head straightening → flying saw cutting.

4. Online equipment project:

4.1 Non standard equipment:

No | name | quantity | Remarks |

1 | Coil car | 1 set | AC motor |

2 | Uncoiler | 1 set | AC motor |

3 | Straight head pinch leveler | 1 set | AC 1.5KW |

4 | Shear welder | 1 set | |

5 | Horizontal accumulator | 1 set | |

6 | Entrance leveler | 1 set | |

7 | Forming unit | 1 set | DC2X132KW |

8 | HF Welder | 1 set | 600KW |

9 | Water cooling device | 1 set | |

10 | Sizing unit | 1 set | DC motor 160KW |

11 | Sawing roller table | 1 set | |

12 | Collection stand | 1 set | |

13 | Hydraulic system | 1 set | |

14 | Electric control system | 1 set | |

15 | Foundation bolt | 1 set | |

16 | Computer flying saw (flat push saw) | 1 set | DC |

4.2 Outsourced supporting equipment:

N/N | Equipment name | qty | Manufacturer |

1 | 600KW high-frequency welder (solid state) | 1 | Domestic |

2 | CO2 gas shielded welder and trolley | 1 | Domestic |

3 | roll | Domestic |

If you want to quote or further information on this product, please fill out the form below.

-

Used hydro tester

Used hydro tester

-

No.175 used 500x500mm direct forming tubemill

No.175 used 500x500mm direct forming tubemill

-

used (4-12.7)xOD273mm ERW tubemill

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

No.194 500x500mm Direct square welder unit

No.194 500x500mm Direct square welder unit

-

2016 used OD219×(3-8)mm ERW tubemill

2016 used OD219×(3-8)mm ERW tubemill

-

No.198 New OD 377 tubemill

No.198 New OD 377 tubemill

-

used OD235-OD400 ERW Tubemill

used OD235-OD400 ERW Tubemill

-

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

-

No. 196 6 station tube hydro testing machine

No. 196 6 station tube hydro testing machine

-

ET No.94 Used stainless steel ERW tube mill

ET No.94 Used stainless steel ERW tube mill

-

No.179 Used tube mill OD 165mm

No.179 Used tube mill OD 165mm

-

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

-

No.195 auto strapping machine for steel tube and steel pipe or steel coil

No.195 auto strapping machine for steel tube and steel pipe or steel coil

-

new ERW tube mill

new ERW tube mill

-

No.186 4 station tube hydro testing machine

No.186 4 station tube hydro testing machine

-

OD21-76mm ERW tubemill

OD21-76mm ERW tubemill

-

Φ165-Φ235mm ERW tubemill

Φ165-Φ235mm ERW tubemill

-

new ERW tube mill

new ERW tube mill

-

used 200X200X14mm DFT tubemill

used 200X200X14mm DFT tubemill

-

used 250x250x12mm square direct forming ERW tubemill

used 250x250x12mm square direct forming ERW tubemill

-

used 30×30mm~80×80mm ERW tubemill

used 30×30mm~80×80mm ERW tubemill

-

ET No.142 Used 325 ERW tube mill

ET No.142 Used 325 ERW tube mill

-

No.176 WG377 tube mill

No.176 WG377 tube mill

-

ET No.159 Used 325mm Stainless steel ERW Tube mill

ET No.159 Used 325mm Stainless steel ERW Tube mill

-

Used straightening machine

Used straightening machine

-

OD45-105mm ERW Tubemill

OD45-105mm ERW Tubemill

-

ET No.171 Used ERW tubemill

ET No.171 Used ERW tubemill

-

200×200×14mm direct forming tubemill

200×200×14mm direct forming tubemill

-

used 40×40mm~100×100mm ERW tubemill

used 40×40mm~100×100mm ERW tubemill

-

new ERW tube mill

new ERW tube mill

-

No. 193 New edge milling machine

No. 193 New edge milling machine

-

2018 Nanyang OD12.7-50mm ERW tubemill

2018 Nanyang OD12.7-50mm ERW tubemill

-

No.177 Used tube mill OD 325mm (12 in)

No.177 Used tube mill OD 325mm (12 in)

-

Used end facing machine

Used end facing machine

-

2007 Chinese Brand 400x400mm square tube direct forming tubemill

2007 Chinese Brand 400x400mm square tube direct forming tubemill

-

ERWΦ219 tubemill

ERWΦ219 tubemill

-

used DFT 400x400mm ERW tubemill

used DFT 400x400mm ERW tubemill

-

No.189 12 in used ERW API Tubemill

No.189 12 in used ERW API Tubemill

-

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

-

2002-2003 OD219-508×16mm ERW tubemill API

2002-2003 OD219-508×16mm ERW tubemill API

-

No. 199 114 high frequency welded pipe mill unit

No. 199 114 high frequency welded pipe mill unit

-

No.197 New MH50 high frequency welded pipe mill unit

No.197 New MH50 high frequency welded pipe mill unit

-

2007 used 5-12.5×300×300mm DFT

2007 used 5-12.5×300×300mm DFT