Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

ERW Tube Mill

ERWΦ219 tubemill

ERWΦ219 tubemill, model No. 215, it is written on Jan. 29, 2022. It's on sale, delivery time: 30days only- product description

- Technical Parameters

1General introduction: | ||

ERWΦ219 solid state welder pipe production line, it is used to produce welded steel pipes with OD89 ~ OD219mm and wall thickness of 2.75 ~ 8.0mm. It has innovative design, high degree of automation, convenient operation and maintenance, and is in a leading position in design level and manufacturing quality. | ||

2Production plan | ||

2.1technical parameter | ||

Name | Content | |

Product standard | GB/T3091, ASTM A53, BS1387, JIS3466 | |

Specifications | Round tubeOD89~OD219mm, Square tube 75*75,100*100,125*125,150*150,125*75,150*100, | |

Wall thickness | 2.75~8.0 mm | |

Pipe length | 6 m | |

Length tolerance | ±3 mm | |

Line speed | 25~45m/min | |

Feeding type | ○left ○right | |

2.2Raw material specification | ||

Name | Content | |

Coil material | hot rolled steel | |

Coil OD | Ø1500~Ø1800mm | |

Coil ID | Ø508、Ø610 | |

Weight | Max 15ton | |

Strip width | 280~6700mm | |

Width tolerance | 0~0.5mm | |

Thickness | 2.75~8.0mm | |

Thickness tolerance | Max.±5% | |

Strip bending | Max.20mm/10m | |

Strip edge | Longitudinal shear | |

Strip grade | Q195、Q215、Q235、Q345 | |

yield strength | Max. 350Mpa / Min. 235Mpa | |

tensile strength | Max. 550Mpa | |

2.3production capacity:80,000t/ single shift per year |

2.4total power requirement: 2,000KVA |

3Equipment process flow |

Uncoiling → shear welder → horizontal accumulator storage → feeding → forming → extrusion welding → cooling → sizing → cutting to length → packaging → warehousing |

4layout |

Forming: 7 horizontal stands8 vertical stands Sizing: 5 horizontal stands5 vertical stands , 4 roll Turk head, 2 stands WP WL JP WL 1CP 1CL 2CP 2CL 3CP 3CL 4CP 4CL 5CL 6CL 5CP 7CL 6CP8CL 7CP HD HJ HB1, 2 HM SL 1DL 1DP 2DL 2DP 3DL 3DP 4DL 4DP 5DL 5DP T1 T2 WP—feeding horizontal rolls JP — 5 roll leveling (no power) WL — feeding vertical rolls, CL — forming vertical rolls, CP — forming horizontal rolls HD — guiding stands HJ — squeeze stand (2 roll type) HB — remove tube outside burr HM — grinding stands SL — cooling water tank DL — sizing vertical rolls DP — sizing horizontal rolls T — Turk head |

5Scope of supply and quotation | |||

No. | Name | QTY | Remark |

1 | coil car | 1 | |

2 | double cone uncoiler | 1 | |

3 | coil opener | 1 | |

4 | pinching and leveling machine | 1 | |

5 | shear welder | 1 | |

6 | spiral horizontal accumulator | 1 | |

7 | forming machine | 1 | |

8 | welding device | ||

9 | cooling tank | ||

10 | sizing machine | ||

11 | solid state welder | 1 | 600KW |

12 | Milling cutter | 1 | |

13 | run out table | ||

14 | end facing/chamfering machine | 1 | |

15 | hydro tester | 1 | |

16 | electric system | 1 | |

17 | hydraulic system | 1 | |

18 | rolls | 9 | 9 set (2 of them are only half set) |

total | 22 | ||

6Description of main equipment (The following equipment photos are for reference only and are not used as acceptance basis ) | ||||||

6.1 coil car | ||||||

Name | Content | |||||

Function | Load the steel coil and transport the steel coil to the uncoiler | |||||

technical parameter | Trolley lifting mode: Hydraulic cylinder Trolley operation mode: Electric 2m/min Coil OD: Φ1500~Φ2200mm Coil width: 350~700mm Max coil weight: 15T Protective plates are added on both sides of the V-shaped groove of the lifting trolley. The lifting guide column of the trolley is a double guide force column. The chain tension of the transmission motor is adjustable. | |||||

6.2uncoiler | ||||||

Name | Content | |||||

Function | double cone uncoiler is used to support the coil and provide raw materials for the production line. The machine has two cones. It mainly includes base, pneumatic brake device and electrical control system. The machine is equipped with direct feeding and guiding. The coil is first placed on the uncoiling cone head. When guiding, the guiding roller is pressed down hydraulically, and the coil is actively rotated by the motor. Under the action of the shovel head machine, the coil enters shear butt welding; The braking mode is controlled by the linkage of the whole line to ensure that the strip steel does not loose during operation. | |||||

technical parameter | Max coil weight: 15 ton Main motor: 4KW Coil thickness: 2.75~8.0mm Coil ID: Φ508, Φ610mm Braking mode : Pneumatic | |||||

6.3 coil opener | ||||||

Name | Content | |||||

Function | Auxiliary uncoiling, rough level the strip steel and smoothly send it to the pinch leveler. | |||||

technical parameter | Coil thickness: 3~8mm Roll OD: φ320 mm Extended length of shovel head:500mm Press roll drive: Hydraulic motor | |||||

6.4pinching, feeding and leveling machine | ||||||

Name | Content | |||||

Function | The active pressing roller takes the steel plate apart from the steel coil, and the pinch leveling roller flattens the disassembled steel plate. | |||||

technical parameter | pinching, feeding roller diameter×length Ø160×750mm leveling roller diameter×length Ø120×750mm roller material: 42CrMo roller hardness: HRC48°-52° Pinching, feeding and leveling transmission mode: The clutch between the AC Y2 series motor drive distributor and the reducer, the upper and lower lifting are equipped with synchronous gears, and the rack is equipped with positioning keys. The modulus of the gear and rack shall meet the requirements of forced synchronization. Motor power : 11KW | |||||

6.5shear welder | ||||||

Name | Content | |||||

Function | Hydraulic shearing, automatic welding. It is composed of a front plate moving machine, a plate shearing machine, a rear plate moving machine and a centering device; Hydraulic shear, alignment and flattening. The centering before shearing is changed to have the function of transverse movement, with oil cylinder clamping and motor transverse movement. | |||||

technical parameter | Maximum shear width: 700mm Shear form : It is an up cut type, and the oil cylinder is placed on it. Welding mode: CO2 gas shielded welding (3-year warranty) Shear blade material: 6CrW2Si Shear oil tank diameter: φ200mm Hydraulic system: 16MPa cylinder stroke: 110m

| |||||

6.6spiral horizontal accumulator | ||||||

Name | Content | |||||

Function | Store the steel coil to ensure the continuous production of the unit. The horizontal accumulator is equipped with a mute room. The mute room shall be designed to facilitate maintenance and monitor the internal operation. The sealing of horizontal accumulator transmission system and gearbox shall not leak oil | |||||

technical parameter | horizontal accumulator form: Outside in inside out, fixed circle type. The bottom roller is centrally driven by a DC motor; the pinch roller is hydraulically clamped and driven by a DC motor; the installation form of the DC drive mechanism of the pinch roller is changed to be installed on the ground. Cylinder clamping, DC motor drives. There are steel coil torsion devices at the front and rear of the horizontal accumulator body 。 total storage: 600m effective storage: 400m horizontal accumulator storage laps: 45 filling speed: 100m/min filling motor: DC75Kw Bottom roller diameter: φ180㎜ Bottom rollermotor: DC 132Kw

| |||||

6.7feeding and guiding device | ||||||

Name | Content | |||||

Function | Smoothly guide the flat steel coil into the forming device | |||||

Composition | feeding flat roller、feeding vertical roller、5hi leveling machine、feeding vertical roller | |||||

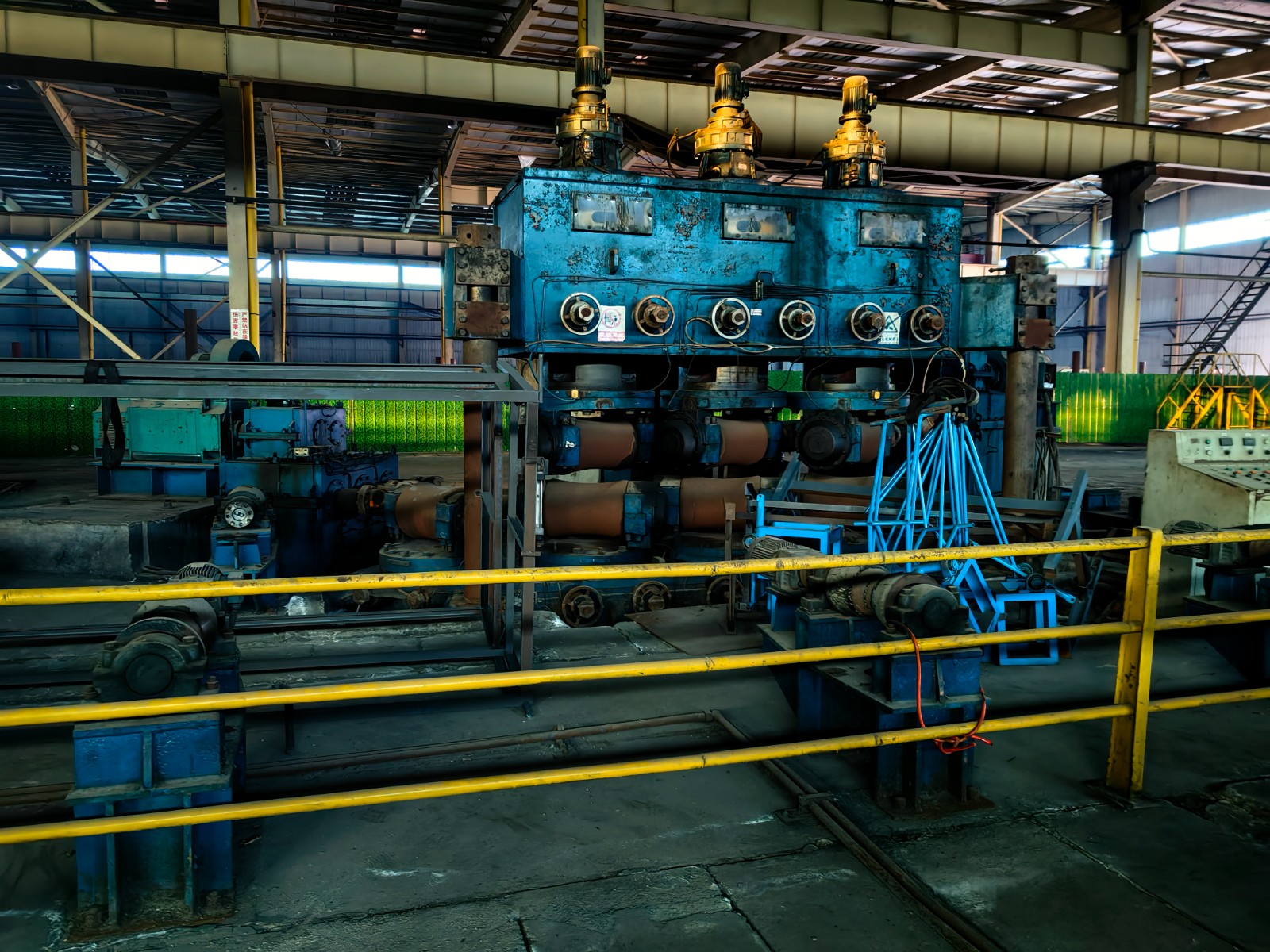

6.8forming machine | ||||||

Name | Content | |||||

Function | Bending straight steel coils to the required cross-section, spacer sleeves with matching rolls (including vertical rolls) | |||||

technical parameter | horizontal roll stands :7 stands | |||||

vertical roll stands :8 stands | ||||||

horizontal roll diameter:Ø130mm, Worm gear pressing down. | ||||||

horizontal roll material: 42CrMo | ||||||

vertical roll diameter : Ø 80mm, Worm gear adjustment. | ||||||

vertical roll material: 40Cr | ||||||

Forming speed:max 50m/min | ||||||

Stand : Casting ZG35 | ||||||

6.9welding device | ||||||

Function : The bent tube blank is welded into a hole shape by high frequency, and the external burr is removed. It consists guiding vertical roll, welder guiding roll,4hi pinching roll, external burr removing machine, 2hi polishing roll stand Spacer sleeves with matched rolls | ||||||

6.10 water cooling tank | ||||||

Cooling tank length :6000mm Air cooling section length:25m Cooling mode: pool spray | ||||||

6.11sizing machine | ||||||

Name | Content | |||||

Function | Eliminate the internal stress of the tube and roll the round tube blank into the required finished tube , | |||||

technical parameter | Universal stand:5 stands, horizontal roll diameter Ø130, worm gearing is pressed down to ensure machining accuracy | |||||

horizontal roll material: 42CrMo | ||||||

horizontal roll stand:5 stands, horizontal roll diameter Ø80, worm gearing adjustment | ||||||

vertical roll material : 40Cr | ||||||

4hi leveling machine stand:4 roll Turk stands2, shaft diameter Ø60mm | ||||||

Sizing speed:max 60m/min | ||||||

Stand: casting ZG35 | ||||||

Finishing and sizing machine has function of quick change | ||||||

6.12、driving device | ||||||

Forming motor:160KW 1000 r/min 2 pcs,sizing motor: 200KW 1000 r/min 2 pcs Driving device consists of main reducer and sub-gearbox. The arc-shaped bevel gear m=16 is used for the sub-speed box, which has the advantages of stable transmission, strong overload resistance and long service life. The material is 20CrMnTi, and the transmission shaft is a heavy-duty transmission shaft.; The main reducer adopts the ZLY type reducer with hard teeth surface 。 | ||||||

6.13、milling cutter | ||||||

Name | Content | |||||

Function | cut the continuously produced steel pipe to the required length, and with noise reduction and silent room | |||||

technical parameter | Sizing accuracy :±3mm Sizing length : 6m Feeding motor:servo5.7 KW*2 Cutter motor: AC 110 KW dragging motor: servo42 KW 2 TCT blade cutting | |||||

6.14、solid state HF welder | ||||||

It is used to heat the two edge metals of the V-shaped mouth of the formed open steel pipe to the welding temperature, closed-circuit distilled water cooling, and control the output power according to the speed of the production line, requiring the use of series solidstate high frequency. | ||||||

technical parameter: ① Design Parameters l Rated DC power:Pd=600kW l Designed frequency :f=250~300kHz l Tank output form: No welding transformer output , secondary resonance ② Power requirements l Rated DC power:Pd=600kW l Rated power factor :COSφ≥0.9 l Power capacity :S≥720kVA l Voltage :3ph 380V/50Hz ③ Circulating soft water cooling system water-water heat exchanger | ||||||

6.15、run out table | ||||||

It is used to transport and store the sawed steel tube, and send the steel tube to the packaging machine. The run out table is a "V" type table, and the structure is electric run out. 。 | ||||||

6.16、Electric control system | ||||||

(1) The main machine forming and sizing electrical control system adopts bus control and PLC control technology, and adopts man-machine interface to realize the synchronous control of each grouping transmission motor. There is necessary interlocking protection and communication interface between main machine forming and sizing and high frequency and saw. (2) The PLC adopts Siemens S7 series, and the mainframe forming and sizing motor adopts DC motor. (3) The main system (excluding the host computer) should realize command control through the man-machine interface, display parameters such as the speed and current of each motor in real time, and demonstrate the operation of the unit. | ||||||

6.17、Hydraulic system | ||||||

1) Pumps, hydraulic valve parts and valves are made of Huade, which conform to international standards and are interchangeable. The oil needs to consider the cooling device. 2) The hydraulic system should ensure the smooth and reliable operation of the hydraulic equipment, and there should be no oil leakage, oil seepage, vibration and other undesirable phenomena. | ||||||

6.18、rolls | ||||||

Name | Content | |||||

technical parameter | material:Cr12 | |||||

Specifications | Heat treatment hardness :HRc58~62 Squeeze roll: 2 sets, Fin pass rolls: 10 PCS, Guiding roll 2 sets, Fin pass rolls: 10 PCS | |||||

7、delivery time(It is recommended to clarify the specific delivery time according to the equipment installation progress ) | ||||||

45 days after receiving down payment | ||||||

8、Main component brands | ||||||

8.1、PLC: SIEMENS S200 8.3、DC governor: PARKER 590 8.4、Servo motor and controller: YASKAWA 8.5、DC motor: Jiangsu Wangpai, Kedi 8.6、AC motor: HengshuiMengniu, YE3 series 8.9、Bearing: HEB、ZWZ、LYC 8.11、Pneumatic components: Jinan HuaNeng 8.12、Hydraulic components: Beijing Huade 8.13、Frequency converter: INVT, one model larger than motor 8.14、DC driver: 590 8.16、Console panel: stainless steel panel | ||||||

5、Scope of supply | ||||

No. | machine name | QTY | remarks | |

1 | coil car | 1 | ||

2 | double cone uncoiler | 1 | ||

3 | coil opener | 1 | ||

4 | pinching and straightening machine | 1 | ||

5 | shear welder | 1 | ||

6 | spiral accumulator | 1 | ||

7 | forming machine | 1 | ||

8 | welding device | |||

9 | cooling tank | |||

10 | sizing machine | |||

11 | solid state HF Welder | 1 | 600KW | |

12 | milling cutter | 1 | ||

13 | Conveyor, run out table | |||

14 | electric system | 1 | Including equipment room cables, excluding main cables and electric control cabinets | |

15 | emulsion system | 1 | ||

16 | hydraulic system | 1 | Including all pipelines | |

17 | rolls | 9 | The final price is calculated according to the actual weight | |

Remark 1:

No | roll sizes | Approximate Weight(t) | remark |

1 | ∅88.9mm | 5 | |

2 | ∅114.3mm | 6 | |

3 | ∅165.1mm | 8 | |

4 | ∅219.1mm | 10 | |

5 | 75*75mm | 6 | |

6 | 100*100mm | 9 | |

7 | 125*125mm | 10 | |

8 | 150*150mm | 11 | |

125*75mm | 4 | Half set | |

150*100mm | 4.5 | Half set | |

73.5 | Approximate weight, the final price is based on the actual weight |

Remarks :roll material; Cr12

Roll price is based on final weight after manufacturing.

If you want to quote or further information on this product, please fill out the form below.

-

new ERW tube mill

new ERW tube mill

-

ET No.159 Used 325mm Stainless steel ERW Tube mill

ET No.159 Used 325mm Stainless steel ERW Tube mill

-

ET No.171 Used ERW tubemill

ET No.171 Used ERW tubemill

-

No.194 500x500mm Direct square welder unit

No.194 500x500mm Direct square welder unit

-

No.175 used 500x500mm direct forming tubemill

No.175 used 500x500mm direct forming tubemill

-

No.195 auto strapping machine for steel tube and steel pipe or steel coil

No.195 auto strapping machine for steel tube and steel pipe or steel coil

-

new ERW tube mill

new ERW tube mill

-

No.186 4 station tube hydro testing machine

No.186 4 station tube hydro testing machine

-

2019 Φ245×8mm ERW tubemill

2019 Φ245×8mm ERW tubemill

-

used 40×40mm~100×100mm ERW tubemill

used 40×40mm~100×100mm ERW tubemill

-

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

-

No.198 New OD 377 tubemill

No.198 New OD 377 tubemill

-

200×200×14mm direct forming tubemill

200×200×14mm direct forming tubemill

-

used OD235-OD400 ERW Tubemill

used OD235-OD400 ERW Tubemill

-

Φ165-Φ235mm ERW tubemill

Φ165-Φ235mm ERW tubemill

-

OD21-76mm ERW tubemill

OD21-76mm ERW tubemill

-

2018 Nanyang OD12.7-50mm ERW tubemill

2018 Nanyang OD12.7-50mm ERW tubemill

-

2016 used OD219×(3-8)mm ERW tubemill

2016 used OD219×(3-8)mm ERW tubemill

-

2002-2003 OD219-508×16mm ERW tubemill API

2002-2003 OD219-508×16mm ERW tubemill API

-

No.189 12 in used ERW API Tubemill

No.189 12 in used ERW API Tubemill

-

2007 used 5-12.5×300×300mm DFT

2007 used 5-12.5×300×300mm DFT

-

used 250x250x12mm square direct forming ERW tubemill

used 250x250x12mm square direct forming ERW tubemill

-

ET No.142 Used 325 ERW tube mill

ET No.142 Used 325 ERW tube mill

-

used 200X200X14mm DFT tubemill

used 200X200X14mm DFT tubemill

-

Used hydro tester

Used hydro tester

-

No. 196 6 station tube hydro testing machine

No. 196 6 station tube hydro testing machine

-

OD45-105mm ERW Tubemill

OD45-105mm ERW Tubemill

-

No.197 New MH50 high frequency welded pipe mill unit

No.197 New MH50 high frequency welded pipe mill unit

-

Used straightening machine

Used straightening machine

-

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

-

No.177 Used tube mill OD 325mm (12 in)

No.177 Used tube mill OD 325mm (12 in)

-

No. 193 New edge milling machine

No. 193 New edge milling machine

-

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

-

used (4-12.7)xOD273mm ERW tubemill

-

No.179 Used tube mill OD 165mm

No.179 Used tube mill OD 165mm

-

Used end facing machine

Used end facing machine

-

used DFT 400x400mm ERW tubemill

used DFT 400x400mm ERW tubemill

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

No.176 WG377 tube mill

No.176 WG377 tube mill

-

No. 199 114 high frequency welded pipe mill unit

No. 199 114 high frequency welded pipe mill unit

-

ET No.94 Used stainless steel ERW tube mill

ET No.94 Used stainless steel ERW tube mill

-

2007 Chinese Brand 400x400mm square tube direct forming tubemill

2007 Chinese Brand 400x400mm square tube direct forming tubemill

-

used 30×30mm~80×80mm ERW tubemill

used 30×30mm~80×80mm ERW tubemill

-

new ERW tube mill

new ERW tube mill