Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

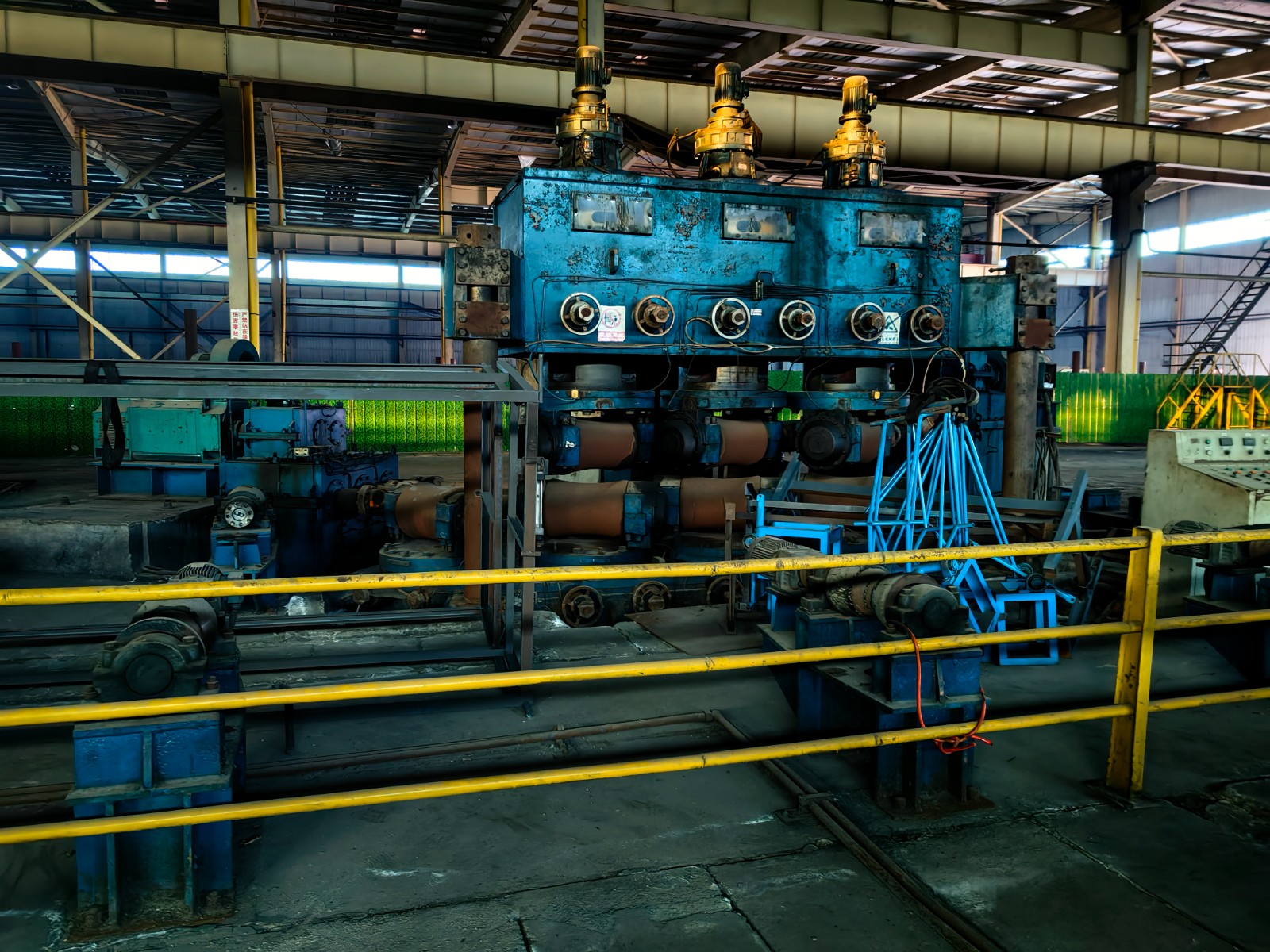

ERW Tube Mill

new ERW tube mill

written date: Feb 27th, 2025, stock No:614- product description

- Technical Parameters

new machine ready for sale

This equipment is specially used for producingΦ50.8-Φ127mm,δ1.0-5.0mm high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe. The composition of equipment is from uncoiler to computer fixed length-cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

Applicable material: The material of steel strip is general carbon steelQ195,Q235,16Mn and etc hot rolled and cold rolled ,pre-galvanized-strip steel.

NO. | Item | Value |

1 |

Round pipe diameter | Φ50.8mm~Φ127mm |

2 |

Round pipe thickness | δ1.0mm~5.0mm |

3 |

Square pipe size | 40×40~100×100mm |

4 |

Square pipe thickness | δ1.0mm~5.0mm |

5 |

Rectangular pipe size | 25×50~80×120mm |

6 |

Rectangular pipe thickness | δ1.0mm~5.0mm |

7 |

Rolling speed | 20M/min~60M/min |

8 |

Pipe length | 3M~8M |

NO. | Item | Value |

1 | thickness | δ1.0~5.0mm |

2 | width | 160~400mm |

3 | O.D. | Φ600mm~Φ1200mm |

4 | I.D. | Φ450mm~Φ550mm |

5 | Maximum | ≤5000kgs |

Square pipe production mode: round changed into square.

production mode: continuous

Operation direction of the machine: left feeding or right feeding (determined by the technological arrangement of the user workshop)

Rolling bottom line: Around +760mm (can be customized according to the requirements from customer)

Welding method: high frequency induction welding, 400KW

Rolling speed: 20-60m/min

Total power consumption of the production line: 840KW Voltage:480V/60HZ

pipe-making process

Raw material (steel strip) → uncoiling → shearing and end welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finishing tube

scope of supply:

uncoiler,shear welder,accumlator,Forming and sizing machine,Cold cutting saw,conveyer table,soild date high-fre welding machine 400kw,

some foreign brands of this machine

Ac motor of equipment: Siemens Beide

Servo motor of cold saw: Yaskawa

Cutting motor of cold saw: siemens

Motion controller of cold saw:British TRIO

Inverter of cold saw:Yaskawa

Electrical components of cold saw: Schneider

If you want to quote or further information on this product, please fill out the form below.

Previous:new ERW tube mill

Next:new ERW tube mill

-

Used OD 12inch ERW tubemill in Shanghai, China

Used OD 12inch ERW tubemill in Shanghai, China

-

Used 26 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

Used 26 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

-

Used H beam production line

Used H beam production line

-

Used 600x600x20mm DFT tubemill line in Shanghai, China

Used 600x600x20mm DFT tubemill line in Shanghai, China

-

new ERW tube mill

new ERW tube mill

-

Used laboratory instrument for API pipes in Shanghai, China

Used laboratory instrument for API pipes in Shanghai, China

-

Used hydro tester

Used hydro tester

-

new ERW tube mill

new ERW tube mill

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

Used OD 20inch ERW tubemill in Shanghai, China

Used OD 20inch ERW tubemill in Shanghai, China

-

Used end facing machine

Used end facing machine

-

Used straightening machine

Used straightening machine

-

Used 12 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

Used 12 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

-

used (4-12.7)xOD273mm ERW tubemill