Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

ERW Tube Mill

No.186 4 station tube hydro testing machine

The written time is June 10,2021.- product description

- Technical Parameters

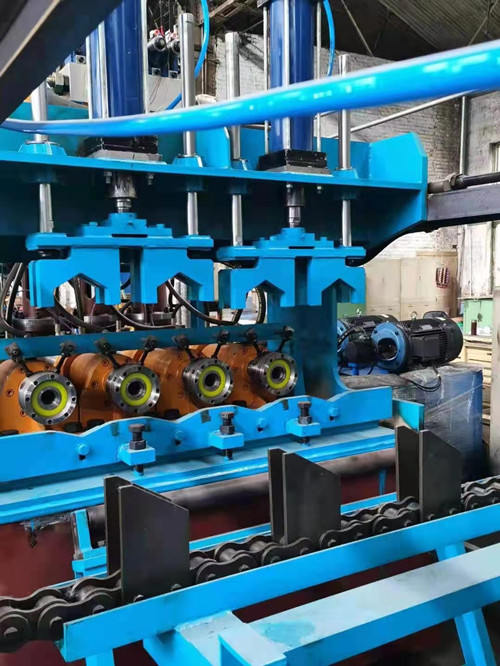

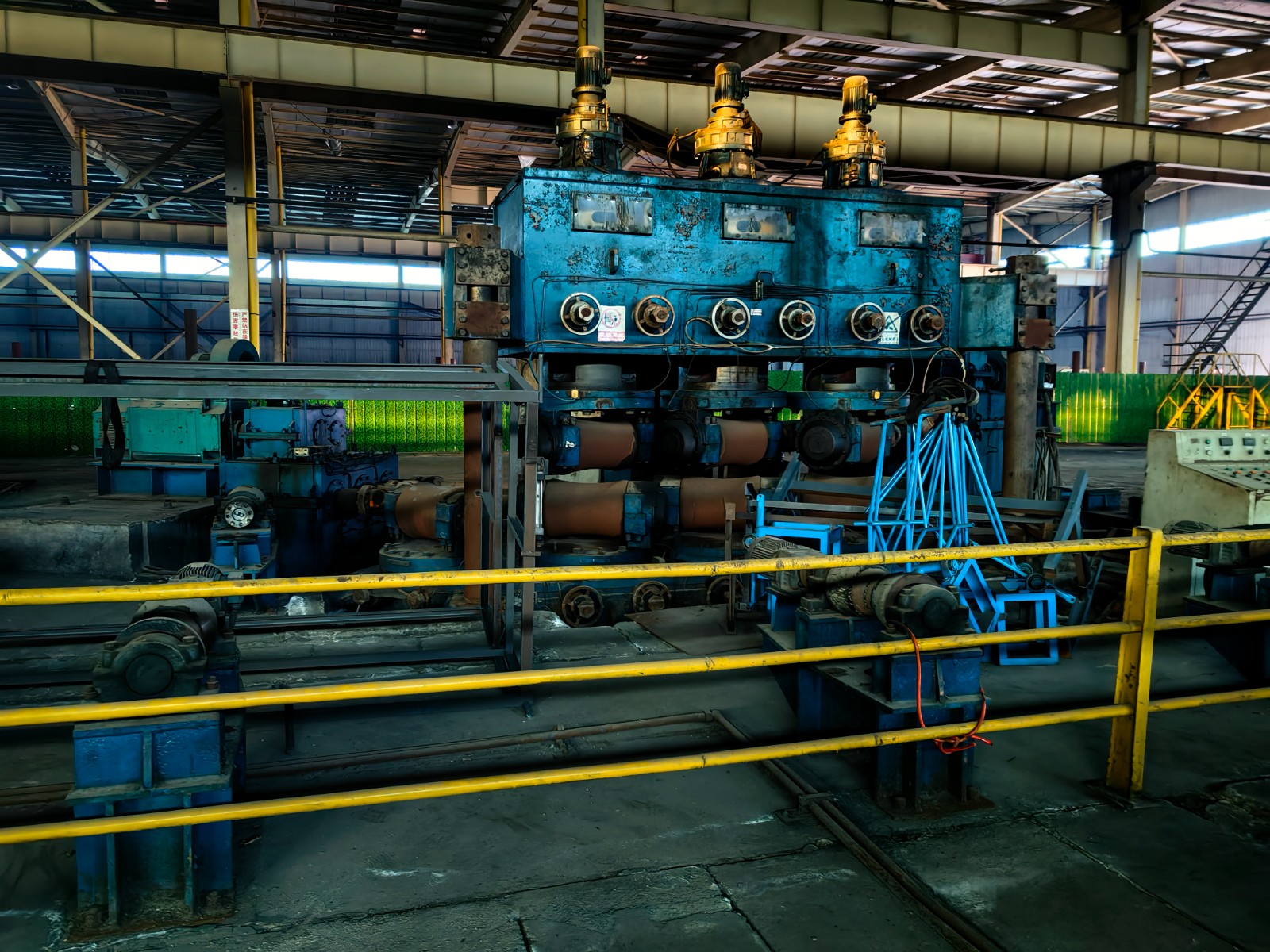

Sy-114-4 4 station tube hydro testing machine

new machine in stock, one year warranty

2. Technical requirements and indicators:

2.1 specification of pressure test pipe: ϕ 76, 89, 114, three specifications, with three kinds of mold, bushing and gasket.

2.2 pressure test pipe steel grade: low and medium carbon steel.

2.3 experimental pressure: 3-7mpa( 30-70 kg).

2.4 pressure test length: 6010 ± 10mm。

2.5 production rhythm (5 MPa pressure holding for 5 seconds), 6-8 pieces / min.

2.6 pressure maintaining form: water injection, full sealing, water cut and pressurization, water cut and pressure maintaining.

2.7 sealing form: face seal.

2.8 test method: cut off water for pressurization and cut off water for pressure maintaining.

2.9 automatic synchronous display: the pressure gauge displays the single pressure value, the touch screen and the large screen display the single pressure value and the pressure curve, the pressure curve can be recorded in the U disk, and the required data can be printed through the offline computer.

3. Process description

3.1 transfer - pushing - clamping - pipe jacking - water injection - plugging - (stop water injection) - pressurization - pressure maintaining - decompression - opening plugging - pipe jacking - Loosening - transfer.

3.2 the hydraulic press is composed of the main machine, supporting hydraulic system, pneumatic system, electrical monitoring and control system, water system, transfer and push system, etc.

4. Configuration and scope of supply

4.1 pressure test head mold: each specification is equipped with a set of pressure test head mold, including sealing gasket, a set of 8 pieces, a total of 2 kinds of 16 pieces.

4.2 water injection pump: 2 sets of pipeline centrifugal pump (30kW).

4.3 hydraulic station: 1 set of double 22KW hydraulic pump system.

4.4 booster oil cylinder device: 4 sets.

4.5 eight pipe jacking cylinders.

4.6 valves and 4 cylinders.

4.7 block 4 cylinders.

4.8 clamp 4 cylinders.

4.9 transmission chain wheel: the main chain wheel is 2.5 inch chain wheel (standard parts) 4, power chain wheel 2.

4.10 transfer motor and reducer assembly 1 set. 5.5kW, controlled by Yaskawa frequency converter,

4.11 push together 1 set of motor and reducer assembly.

4.12 gasket, test 1 set of gasket of each specification, 8 gaskets, 2 kinds in total, 16 gaskets.

4.13 water tank 1 set.

4.14 transfer rack assembly 1 set.

4.15 two sets of pipe jacking body box assembly.

4.16 electric control system console and PLC, touch screen human-machine interface 1 set.

4.17 pressure curve display, 32-55 inch color TV and set top box. The display size is determined according to the site conditions.

4.18 a 32g USB flash disk for storage of pressure data.

5. Require Party A to provide site environment and materials:

5.1 connecting pipes and installation of oil and gas pipelines required for on-site installation.

5.2 connecting wires and cables required on site, communication network cable (30-50m) showing pressing curve and installation.

5.3 foundation bolts shall be installed on site.

5.4 water pump input and output pipes and installation.

5.5 water injection pipeline and installation.

5.6 set up a reservoir 30, and build a circulating ditch around the hydraulic press.

5.7 Party A shall be responsible for the installation and Party B shall guide the installation and commissioning.

5.8 according to the site requirements, move the position of the pressure gauge, provide 32 MPa High pressure oil pipe according to the actual length of the high pressure oil pipe, and the pipe diameter and thread size shall be provided by Party B.

5.9 according to the actual use requirements, Party A shall directly pad the connecting equipment with square pipe on the foundation, which is about 200 square meters. The installation platform of the operation platform is higher than the pipe running position, which is convenient for observation and operation.

If you want to quote or further information on this product, please fill out the form below.

-

2007 Chinese Brand 400x400mm square tube direct forming tubemill

2007 Chinese Brand 400x400mm square tube direct forming tubemill

-

used OD235-OD400 ERW Tubemill

used OD235-OD400 ERW Tubemill

-

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

-

No.179 Used tube mill OD 165mm

No.179 Used tube mill OD 165mm

-

No.189 12 in used ERW API Tubemill

No.189 12 in used ERW API Tubemill

-

No.176 WG377 tube mill

No.176 WG377 tube mill

-

Used hydro tester

Used hydro tester

-

ET No.94 Used stainless steel ERW tube mill

ET No.94 Used stainless steel ERW tube mill

-

No.177 Used tube mill OD 325mm (12 in)

No.177 Used tube mill OD 325mm (12 in)

-

ET No.159 Used 325mm Stainless steel ERW Tube mill

ET No.159 Used 325mm Stainless steel ERW Tube mill

-

Used end facing machine

Used end facing machine

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

used 200X200X14mm DFT tubemill

used 200X200X14mm DFT tubemill

-

used 40×40mm~100×100mm ERW tubemill

used 40×40mm~100×100mm ERW tubemill

-

2016 used OD219×(3-8)mm ERW tubemill

2016 used OD219×(3-8)mm ERW tubemill

-

2019 Φ245×8mm ERW tubemill

2019 Φ245×8mm ERW tubemill

-

used 250x250x12mm square direct forming ERW tubemill

used 250x250x12mm square direct forming ERW tubemill

-

used 30×30mm~80×80mm ERW tubemill

used 30×30mm~80×80mm ERW tubemill

-

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

-

No.198 New OD 377 tubemill

No.198 New OD 377 tubemill

-

new ERW tube mill

new ERW tube mill

-

ET No.171 Used ERW tubemill

ET No.171 Used ERW tubemill

-

No.194 500x500mm Direct square welder unit

No.194 500x500mm Direct square welder unit

-

new ERW tube mill

new ERW tube mill

-

used (4-12.7)xOD273mm ERW tubemill

-

2002-2003 OD219-508×16mm ERW tubemill API

2002-2003 OD219-508×16mm ERW tubemill API

-

used DFT 400x400mm ERW tubemill

used DFT 400x400mm ERW tubemill

-

200×200×14mm direct forming tubemill

200×200×14mm direct forming tubemill

-

No.195 auto strapping machine for steel tube and steel pipe or steel coil

No.195 auto strapping machine for steel tube and steel pipe or steel coil

-

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

-

ERWΦ219 tubemill

ERWΦ219 tubemill

-

new ERW tube mill

new ERW tube mill

-

OD45-105mm ERW Tubemill

OD45-105mm ERW Tubemill

-

No.175 used 500x500mm direct forming tubemill

No.175 used 500x500mm direct forming tubemill

-

No. 196 6 station tube hydro testing machine

No. 196 6 station tube hydro testing machine

-

OD21-76mm ERW tubemill

OD21-76mm ERW tubemill

-

Φ165-Φ235mm ERW tubemill

Φ165-Φ235mm ERW tubemill

-

ET No.142 Used 325 ERW tube mill

ET No.142 Used 325 ERW tube mill

-

2018 Nanyang OD12.7-50mm ERW tubemill

2018 Nanyang OD12.7-50mm ERW tubemill

-

Used straightening machine

Used straightening machine

-

No. 193 New edge milling machine

No. 193 New edge milling machine

-

No.197 New MH50 high frequency welded pipe mill unit

No.197 New MH50 high frequency welded pipe mill unit

-

No. 199 114 high frequency welded pipe mill unit

No. 199 114 high frequency welded pipe mill unit

-

2007 used 5-12.5×300×300mm DFT

2007 used 5-12.5×300×300mm DFT