Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

ERW Tube Mill

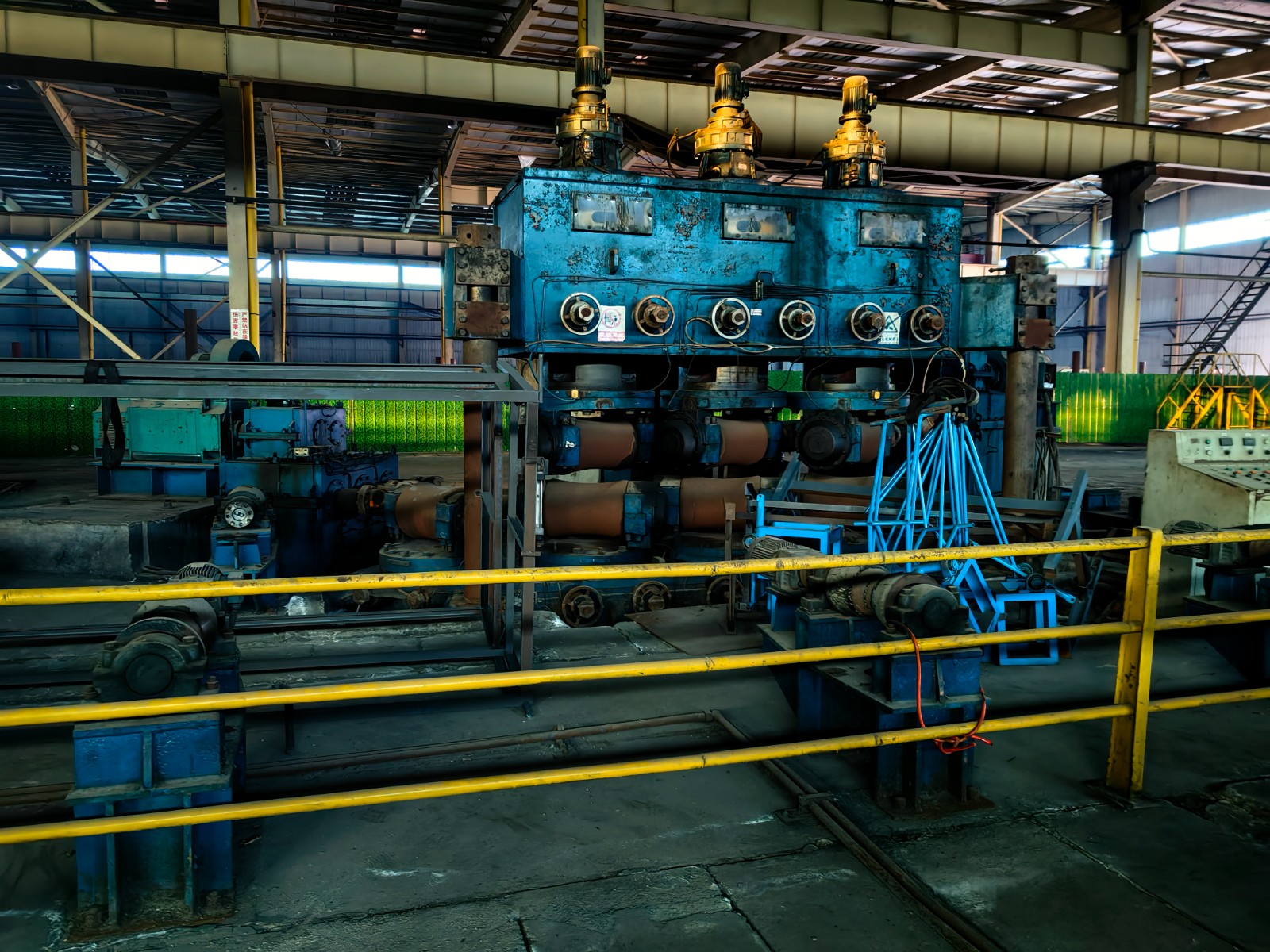

used 250x250x12mm square direct forming ERW tubemill

model No.: 240, it is written on March 2, 2022- product description

- Technical Parameters

I Description and characteristics of the unit:

The unit is used to produce plate with width L = 300 ~ 1000mm and wall thickness= 3 ~ 12mm direct square, rectangular and other closed pipes. The forming of the unit adopts combined rolling spoke, and the rolling catch sharing rate reaches 80%. It is easier to control the accuracy of finished section steel than other forming methods. The electric control part adopts PLC control system and European digital speed regulation unit. The unit has strong universality, wide application range and simple operation and maintenance.

II Technical performance of the unit:

1 finished product

1.1 finished products:

Cold formed hollow section steel for structure:

square pipe mouth 80×80× (3 ~ 6mm) ~ 250×25× (5 ~ 12mm)

Rectangular tube 80×200× (3 ~ 6mm) ~ 150×350×(5 ~ 12mm)

1.2 wall thickness: 3 ~ 12 ( Q235 ) mm

1.3 material: low carbon steel, low alloy steel Q235; Max.q345 (wall thickness < 10)

1.4 length: 6 ~ 15 m

2. Raw material: cold and hot rolled strip coil after slitter

2.1 coil material: low carbon steel, low alloy structural steel Q235; Max.q345 (wall thickness < 10)

2.2 coil width: 300 ~ 1000 mm

Width tolerance: ±0.5 mm

2.3 coil thickness: 3 ~ 12 mm

2.4 coil OD: 1300 - 2100 mm

2.5 coil ID: Φ610; Φ700; Φ760 mm

2.6 coil weight: < 25 tons

3. Main performance of the unit:

3.1 forming method: Roll forming

3.2 forming welding speed: 10 ~ 30 m/min

3. Welding method: High frequency induction welding

3.4 welding power: 800 KW

3.5 unit type: undetermined

3.6 unit production capacity: Two shift system: 60,000 ~ 120,000 tons

4. Workshop conditions:

4.1 power supply: AC380V 50HZ

Control power supply: AC220V 50HZ

4.2 compressed air flow: 4 m3/min

Pressure: 0.7 MPa

4.3 circulating water source flow 160 t / h

pressure 0.3 Mpa

4.4 assembly machine capacity:

4.5 floor area of workshop: 142m×l8m

4.6 lifting capacity of workshop: 25t and 5T bridge crane each 1 set

4.7 unit elevation: 900mm

Ⅲ Production process flow:

raw material--loading-- uncoiling-- coil opener--pinching and leveling--bud cutting head and tail---centering welding-- looper storage - inlet guide device--forming-- high frequency welding-- deburring--cooling-- sizing--cutting to length-- storage

Ⅳ Online equipment composition:

No. | name | Qty | remark |

1 | coil car | 1 | |

2 | uncoiler | 1 | |

3 | coil opener | 1 | |

4 | Shear welder | 1 | Including CO2 welder and trolley |

5 | Horizontal spiral looper | 1 | |

6 | Host hydraulic system | 1 | |

7 | Forming device | 1 | Including inlet guide |

8 | Welding device | 1 | Including transformer lifting support |

9 | HF welder (800KW) | 1 | American brand |

10 | cooling system | 1 | |

11 | Sizing unit | 1 | |

12 | Computer flying saw | 1 | Chinese brand |

13 | Roll table | 1 | Including material shifting device |

14 | Collection bench | 1 | Supplied by user |

15 | Electric control system | 1 |

5、 Introduction to main equipment:

1 coil car:

Purpose: it is used to undertake the steel coil and transport it to the uncoiler, and lift the steel coil to the center of the uncoiling cone head. The maximum lifting coil weight is 25 tons.

Structure composition: it is composed of material rack, traveling device, idler, oil cylinder, guide rail, etc.

Lifting mode: hydraulic pressure

Walking mode: YEJ motor with cycloid reducer drive

2 Uncoiler:

Purpose: align the center line of the strip steel rolling unit.

Structural form: The double cone head can move left and right

Drum movement mode: hydraulic pressure

Drum rotation mode: AC drive

Drum braking and micro braking mode: Pneumatic

Uncoiling speed: 6 m/min

3 coil opener:

Usage: it is used to remove, straighten, level and deliver the steel strip prepared by the uncoiler.

Structure: it is composed of pressing roller device, shovel head device, straightening head device, pinch roller, leveling roller and transmission device.

Press spoke transmission mode: AC motor

Telescopic swing mode of shovel head: hydraulic pressure

Clamping and screwdown mode: hydraulic pressure

Flattening and screwdown method: Hydraulic screwdown

Number of leveling spokes: 5 rolls

Transmission mode of clamping leveling rod: AC motor drive

4. Shear butt welding device:

Purpose: cut and align the head and tail of steel coil respectively, and butt weld the head and tail.

Structure: hydraulic shear, front and rear pinch roll, front and rear neutral roll, CO2 protective welding device.

Pressing method: hydraulic pressure

Hydraulic shear: Oblique blade shear

Cut material: Low carbon steel as < 325 MPa

Shear thickness: Maximum 12mm (Q235)

Welding method: CO2 shielded welding

5. Horizontal spiral looper:

Purpose: to store the strip steel and ensure the continuous and stable production of the unit during the time of winding, uncoiling and butt welding. Structure: horizontal spiral looper, external inlet and internal outlet, DC motor drive feeding, fixed coil system.

Charging speed: 20 ~ 80 m/min

Storage length: Max.700m

Transmission mode: The silo adopts separate drive

6. Molding unit:

Forming method: roll forming

Inlet guide device: active two roller pinch belt clutch, passive five roller leveling, two groups of manual vertical rollers adjusted separately

It is composed of six flat roll frames, four four roll universal frames and three vertical roll frames.

It is driven by two motors in two groups

Forming speed: 10 ~ 30 m/min

Forming drive: Spiral umbrella reducer

Forming motor: Dc160kwx 2 sets

7 Welding unit:

It is composed of 5 roll extrusion roller frame, external burr removal frame, rolling frame and transformer support. The upper roller can be adjusted individually or as a whole, with fine adjustment on the left and right and cantilever structure

8 cooling system:

Function: used to cool the welded pipe blank.

Structure: it is composed of cooling water tank, sprinkler, base and other parts.

9 Sizing unit:

It is composed of one vertical roller, four 4 universal frames and 2 Turkish heads. DC motor is driven centrally.

Sizing speed: 10 - 30 m/min

Sizing motor: DC160KW

10 Equipment model: fj250 microcomputer controlled fixed length flying saw

10.1 basic parameters

Applicable varieties: square tube 80x80 ~ 250x250x12

Rectangular tube max350x 150x 12

Steel pipe arm thickness: 5 ~ 12mm

Material strength: O, w420mpa, obw550mpa

(the maximum thickness of Q345 is 10mm, and the maximum thickness of Q235 is 12mm)

Sawing length: 6 ~ 15m

Sizing error: ± 3mm

Suitable rolling speed: 5 ~ 30m / min

Sawing mode: hydraulic swing type

Lower thread positioning of the unit (rectangular pipe riser)

10.2 main parameters and functions of equipment

Total power: 260kw

Saw blade diameter: 1400mm (linear speed: 108m / s)

Clamping mode: the clamp is divided into front clamp and rear clamp, both of which have the functions of lower clamp and left and right clamp. There is no oil cylinder on one side of the front fixture for screw adjustment and positioning.

Equipment function: the operation has manual and automatic functions; Can cut long ruler and short ruler

The fixed length can be adjusted at any time.

Control system: high sensitivity servo system and high-precision position system are adopted. The DC governor adopts Euro 590 + series.

11 Roller table after sawing:

Function: output and collect the finished welded pipe backward.

If you want to quote or further information on this product, please fill out the form below.

-

Used hydro tester

Used hydro tester

-

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

-

ERWΦ219 tubemill

ERWΦ219 tubemill

-

No. 199 114 high frequency welded pipe mill unit

No. 199 114 high frequency welded pipe mill unit

-

No.177 Used tube mill OD 325mm (12 in)

No.177 Used tube mill OD 325mm (12 in)

-

No.175 used 500x500mm direct forming tubemill

No.175 used 500x500mm direct forming tubemill

-

Used end facing machine

Used end facing machine

-

2002-2003 OD219-508×16mm ERW tubemill API

2002-2003 OD219-508×16mm ERW tubemill API

-

No.197 New MH50 high frequency welded pipe mill unit

No.197 New MH50 high frequency welded pipe mill unit

-

used DFT 400x400mm ERW tubemill

used DFT 400x400mm ERW tubemill

-

No.195 auto strapping machine for steel tube and steel pipe or steel coil

No.195 auto strapping machine for steel tube and steel pipe or steel coil

-

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

-

200×200×14mm direct forming tubemill

200×200×14mm direct forming tubemill

-

ET No.159 Used 325mm Stainless steel ERW Tube mill

ET No.159 Used 325mm Stainless steel ERW Tube mill

-

used (4-12.7)xOD273mm ERW tubemill

-

used 40×40mm~100×100mm ERW tubemill

used 40×40mm~100×100mm ERW tubemill

-

2019 Φ245×8mm ERW tubemill

2019 Φ245×8mm ERW tubemill

-

No.189 12 in used ERW API Tubemill

No.189 12 in used ERW API Tubemill

-

2007 used 5-12.5×300×300mm DFT

2007 used 5-12.5×300×300mm DFT

-

No.194 500x500mm Direct square welder unit

No.194 500x500mm Direct square welder unit

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

No.179 Used tube mill OD 165mm

No.179 Used tube mill OD 165mm

-

No.198 New OD 377 tubemill

No.198 New OD 377 tubemill

-

ET No.142 Used 325 ERW tube mill

ET No.142 Used 325 ERW tube mill

-

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

-

No.176 WG377 tube mill

No.176 WG377 tube mill

-

OD21-76mm ERW tubemill

OD21-76mm ERW tubemill

-

No. 196 6 station tube hydro testing machine

No. 196 6 station tube hydro testing machine

-

ET No.171 Used ERW tubemill

ET No.171 Used ERW tubemill

-

new ERW tube mill

new ERW tube mill

-

new ERW tube mill

new ERW tube mill

-

used OD235-OD400 ERW Tubemill

used OD235-OD400 ERW Tubemill

-

used 30×30mm~80×80mm ERW tubemill

used 30×30mm~80×80mm ERW tubemill

-

ET No.94 Used stainless steel ERW tube mill

ET No.94 Used stainless steel ERW tube mill

-

2018 Nanyang OD12.7-50mm ERW tubemill

2018 Nanyang OD12.7-50mm ERW tubemill

-

No.186 4 station tube hydro testing machine

No.186 4 station tube hydro testing machine

-

Used straightening machine

Used straightening machine

-

Φ165-Φ235mm ERW tubemill

Φ165-Φ235mm ERW tubemill

-

2016 used OD219×(3-8)mm ERW tubemill

2016 used OD219×(3-8)mm ERW tubemill

-

No. 193 New edge milling machine

No. 193 New edge milling machine

-

new ERW tube mill

new ERW tube mill

-

OD45-105mm ERW Tubemill

OD45-105mm ERW Tubemill

-

used 200X200X14mm DFT tubemill

used 200X200X14mm DFT tubemill

-

2007 Chinese Brand 400x400mm square tube direct forming tubemill

2007 Chinese Brand 400x400mm square tube direct forming tubemill