Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

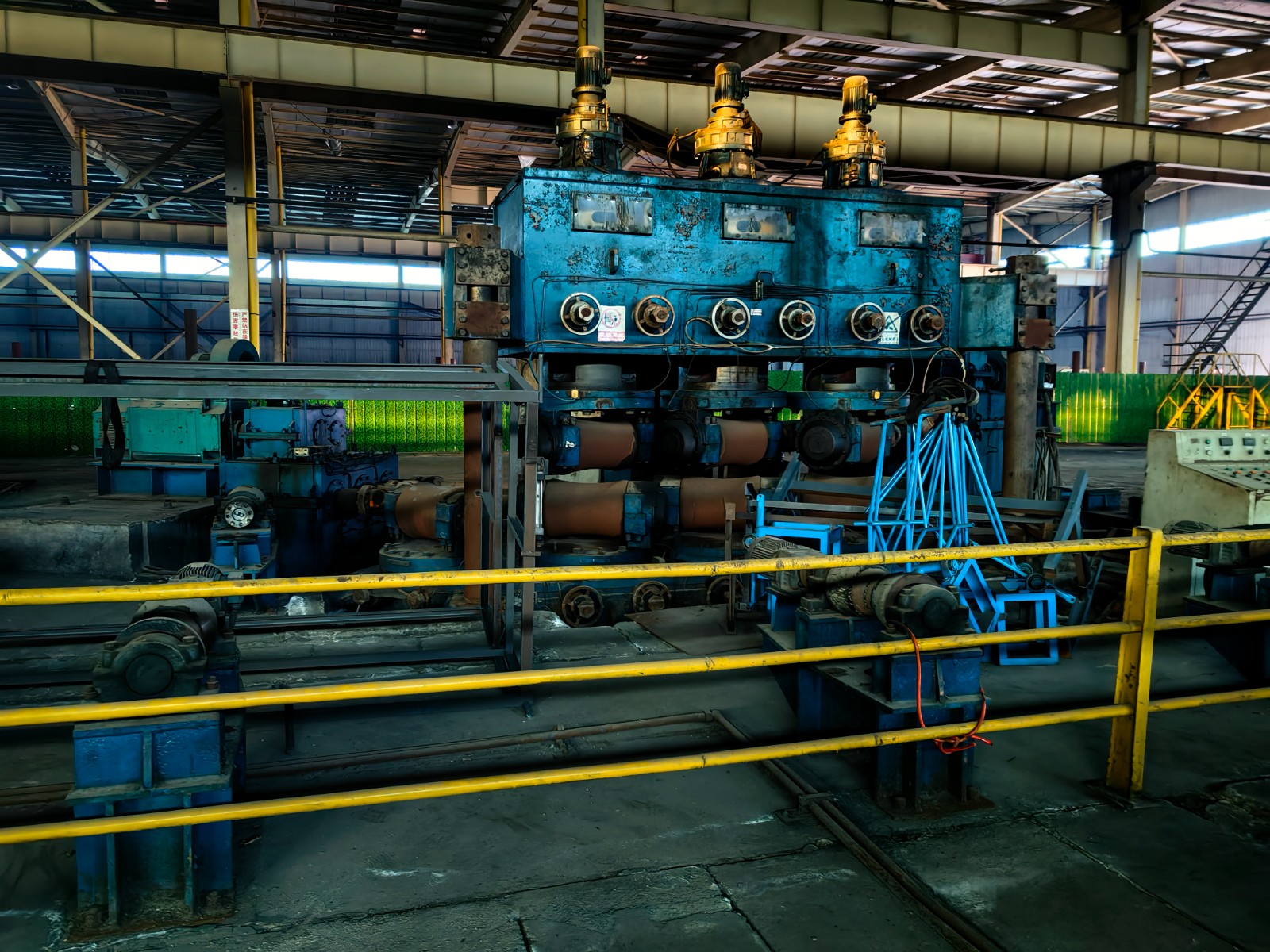

ERW Tube Mill

used OD235-OD400 ERW Tubemill

Model No.: 231, it is written on March 1st, 2022

- product description

- Technical Parameters

Φ235-Φ400mm ERW Tubemill

machine was made in 2004, is still on line at present

1. Technical performance

1.1 coil thickness: 5-12mm

coil width: 600-1250 mm

material: API X60

coil OD: MaxΦ 2000 mm

coil ID:Φ610-Φ760 mm

coil weight: max20t

1.2 finished products

tube OD:Φ235-Φ400mm

wall thickness: 5-12mm

tube length: 8-30m

tube Weight: max2713 kg

1.3 production mode

Forming method: row roll forming method.

Welding method: high frequency welding, medium frequency annealing (reserved).

1.4 unit operating speed: 10-30m / min

1.5 annual production: 120,000 tons

2. Unit process flow

Raw steel coil - uncoiling - head removal - leveling - feeding looper - centering - shear butt welding - centering - pinch roller - spiral horizontal looper - pinch conveyor - centering - centering - feeding - forming - high frequency welding - cooling - ultrasonic flaw detection (reserved) - air cooling - anti torsion device - medium frequency annealing (reserved) - water cooling (reserved) --Sizing - cutting - tube delivery - trimming area - material storage area - flat head chamfering - hydraulic test - post hydraulic inspection - finished product inspection - weighing, length measurement, marking - Storage

3. Introduction to main equipment

3.1 uncoiler

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

material: API X60

coil OD: Max Φ 2000mm

coil ID: Φ610-Φ760mm

Steel coil weight: max20t

-The double cone hydraulic alignment is adopted, the feeding trolley is used for coil preparation, the feeding trolley is raised and lowered by hydraulic pressure, and the cone head is driven by motor and reducer to open the coil actively.

-The transmission motor is 15kw, the uncoiling speed is 15m / min, and the trolley is driven by the motor.

3.2 head remover

The hydraulic swing blade head is adopted, and the upper pressing roller is used to uncoil actively.

3.3 pinch leveler

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

material: X60

-Leveling roll 5 (upper 2 / lower 3) is active and pressed down hydraulically.

-DC motor for transmission is 55kW, and the running speed is 55m / min.

3.4 shear welding machine

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

material: X60

-The hydraulic up cutting shear cuts the plate head and plate tail, and is provided with a plate head and plate tail collection groove.

-Butt weld the plate head and plate tail. Hydraulic lifting butt welding table.

-Butt welding method: CO2 automatic welding. Welding speed: 0.5-1.5m/min

3.5 pinch conveyor

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

speed: Max 55m / min

-Delivery roll diameterΦ280mm motor dc160kwHydraulic press down.

-The machine has its own protection function and can operate normally when the plate thickness changes suddenly.

3.6 spiral horizontal looper

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

material: X60

Drive motor DC55kw

3.7 pinch roll

Technical parameters: coil thickness: 5-12m

coil width: 600-1250mm

speed: Max 30m / mm

Delivery roll diameterΦ280mm, motor DC90kw, hydraulic pressing down.

3.8 feeder

Technical parameters: coil thickness: 5-12mm

coil width: 600-1250mm

speed: max30m / min

-Clamping before break down

-Feed roller diameterΦ280m, motor dc45kw, hydraulic press down.

3.9 forming machine

Technical parameters: steel pipe specification:Φ235-Φ400mm

Steel pipe wall thickness: 5-12mm

Steel pipe material: X60

-The adjustable roll arrangement is adopted for forming, and the roll arrangement is passive.

-3 fin pass machine, pressing mode: electric.

-The 3 fin pass machine are all driven separately, and the motor is DC45KW × 3.

horizontal shaft diameter: 220mm, vertical shaft diameter:

-Newly added molding machine entrance rent molding bending power rack, equipment weight 20ton

Add 1 forming bending frame:

The cover can be opened quickly

The upper roll is pressed down electrically, and the height of the lower roll is adjustable:

Gear box transmission is adopted (transmission type of existing sizing machine)

Separate drive, DC motor.

-The equipment weight of arc vertical roller is 5ton

1 set of arc vertical roller: placed behind the new booster bending frame.

Straight top side pressing screw rod (non cantilever type)

Manual adjustment of vertical roll.

3.10 welding device

Technical parameters: steel pipe specification:Φ235-Φ400 mm

Steel plate wall thickness: 5-12mm

Welding method: high frequency welding

Welding speed: 10-30m / min

-The 4 roller extrusion welding device has the advantages of reasonable mechanism setting, convenient adjustment and easy disassembly.

-High frequency welding machine, 800KW.

-Remove internal and external burrs.

3.11 sizing machine

Technical parameters: steel pipe specification:Φ235-Φ400mm

Steel plate wall thickness: 5-12mm

Steel pipe material: X60

-4 roll sizing, 3 in total

-Each drive is driven separately, and the motor is DC90KW×3。

-With Turkish head.

3.12 hobbing machine

Technical parameters: tube OD: Φ235-Φ400mm

coil thickness: 5-12mm

material: X60

-Pneumatic operation mode is adopted

-Cutter rotating motor AC75KW

-Roll cutting flying saw, equipment weight 1ton

Redesign the hobbing head to ensure Φ235-Φ400mm Adjustment range

3.13 hydraulic system

Technical parameters: system working pressure: 12MPa, 20MPa

-The hydraulic station is composed of pump station, valve station and pipeline.

-Rexroth series is selected as the valve.

3.15 electric control system

-The electric control system consists of DC control system, AC control system and PLC control system.

-The components of the system are produced by Chinese famous brand manufacturers or joint venture manufacturers.

4. Installed capacity of the unit: (total motor power DC900KW + AC250KW + high frequency welding machine 800KVA) total:

1950KW

5. Equipment name (scope of supply)

No. | name | QTY | weight (T) | remarks |

1 | Roll up trolley | 1 | 3 | |

2 | Uncoiler | 1 | 9 | |

3 | Head remover | 1 | 5 | |

4 | Lead leveler | 1 | 14 | |

5 | Shear butt welding machine | 1 | 10 | exclude automatic welding machine |

6 | Centering device | 4 | 3×4 | |

7 | Pinch roll | 1 | 8 | |

8 | Spiral horizontal accumulator | 1 | 125 | |

9 | Pinch conveyor | 1 | 8 | |

10 | Feeder | 1 | 12 | |

11 | Forming machine | 1 | 170 | |

12 | Welding device | 1 | 24 | exclude HF welding machine |

13 | Anti torsion device | 1 | 20 | |

14 | Water cooling device | 1 | 6 | |

15 | Air cooling device | 1 | ||

16 | Φ165, 185, 250, 360, 404mm roll | 1 | 20 | |

17 | Φ235mm roll | 2 | 20 | |

18 | Sizing machine(3 stands) | 1 | 70 | |

19 | Cutting machine | 1 | 19 | |

20 | Hydraulic system | 1 | 8 | |

21 | Electric control system | 1 | 3 |

※Provide:

total weight: 550 tons

Mechanical manufacturing blueprint 2 sets

Installation layout

Roll drawing 2 sets

Inner roll frame drawing 2 sets

If you want to quote or further information on this product, please fill out the form below.

-

No.176 WG377 tube mill

No.176 WG377 tube mill

-

Used straightening machine

Used straightening machine

-

ERWΦ219 tubemill

ERWΦ219 tubemill

-

new ERW tube mill

new ERW tube mill

-

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

ET No.111 Used OTO mills Solid state HF Welder Stainless steel tube mill

-

2018 Nanyang OD12.7-50mm ERW tubemill

2018 Nanyang OD12.7-50mm ERW tubemill

-

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

ET No.110 Used OTO 76.1mm Stainless steel Laser welder tubemill

-

No.177 Used tube mill OD 325mm (12 in)

No.177 Used tube mill OD 325mm (12 in)

-

Used end facing machine

Used end facing machine

-

No.175 used 500x500mm direct forming tubemill

No.175 used 500x500mm direct forming tubemill

-

OD45-105mm ERW Tubemill

OD45-105mm ERW Tubemill

-

used 250x250x12mm square direct forming ERW tubemill

used 250x250x12mm square direct forming ERW tubemill

-

No.194 500x500mm Direct square welder unit

No.194 500x500mm Direct square welder unit

-

No.189 12 in used ERW API Tubemill

No.189 12 in used ERW API Tubemill

-

No.197 New MH50 high frequency welded pipe mill unit

No.197 New MH50 high frequency welded pipe mill unit

-

No. 193 New edge milling machine

No. 193 New edge milling machine

-

ET No.142 Used 325 ERW tube mill

ET No.142 Used 325 ERW tube mill

-

2002-2003 OD219-508×16mm ERW tubemill API

2002-2003 OD219-508×16mm ERW tubemill API

-

No.186 4 station tube hydro testing machine

No.186 4 station tube hydro testing machine

-

new ERW tube mill

new ERW tube mill

-

No. 196 6 station tube hydro testing machine

No. 196 6 station tube hydro testing machine

-

2016 used OD219×(3-8)mm ERW tubemill

2016 used OD219×(3-8)mm ERW tubemill

-

used 200X200X14mm DFT tubemill

used 200X200X14mm DFT tubemill

-

2019 Φ245×8mm ERW tubemill

2019 Φ245×8mm ERW tubemill

-

new ERW tube mill

new ERW tube mill

-

ET No.171 Used ERW tubemill

ET No.171 Used ERW tubemill

-

ET No.94 Used stainless steel ERW tube mill

ET No.94 Used stainless steel ERW tube mill

-

used 40×40mm~100×100mm ERW tubemill

used 40×40mm~100×100mm ERW tubemill

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

No.198 New OD 377 tubemill

No.198 New OD 377 tubemill

-

200×200×14mm direct forming tubemill

200×200×14mm direct forming tubemill

-

Used hydro tester

Used hydro tester

-

Φ165-Φ235mm ERW tubemill

Φ165-Φ235mm ERW tubemill

-

No.195 auto strapping machine for steel tube and steel pipe or steel coil

No.195 auto strapping machine for steel tube and steel pipe or steel coil

-

ET No.159 Used 325mm Stainless steel ERW Tube mill

ET No.159 Used 325mm Stainless steel ERW Tube mill

-

OD21-76mm ERW tubemill

OD21-76mm ERW tubemill

-

used 30×30mm~80×80mm ERW tubemill

used 30×30mm~80×80mm ERW tubemill

-

used DFT 400x400mm ERW tubemill

used DFT 400x400mm ERW tubemill

-

2007 used 5-12.5×300×300mm DFT

2007 used 5-12.5×300×300mm DFT

-

used (4-12.7)xOD273mm ERW tubemill

-

No. 199 114 high frequency welded pipe mill unit

No. 199 114 high frequency welded pipe mill unit

-

2007 Chinese Brand 400x400mm square tube direct forming tubemill

2007 Chinese Brand 400x400mm square tube direct forming tubemill

-

No.179 Used tube mill OD 165mm

No.179 Used tube mill OD 165mm

-

CR No.61 Used 1600mm Cold Bending Roll Forming Machine

CR No.61 Used 1600mm Cold Bending Roll Forming Machine