Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

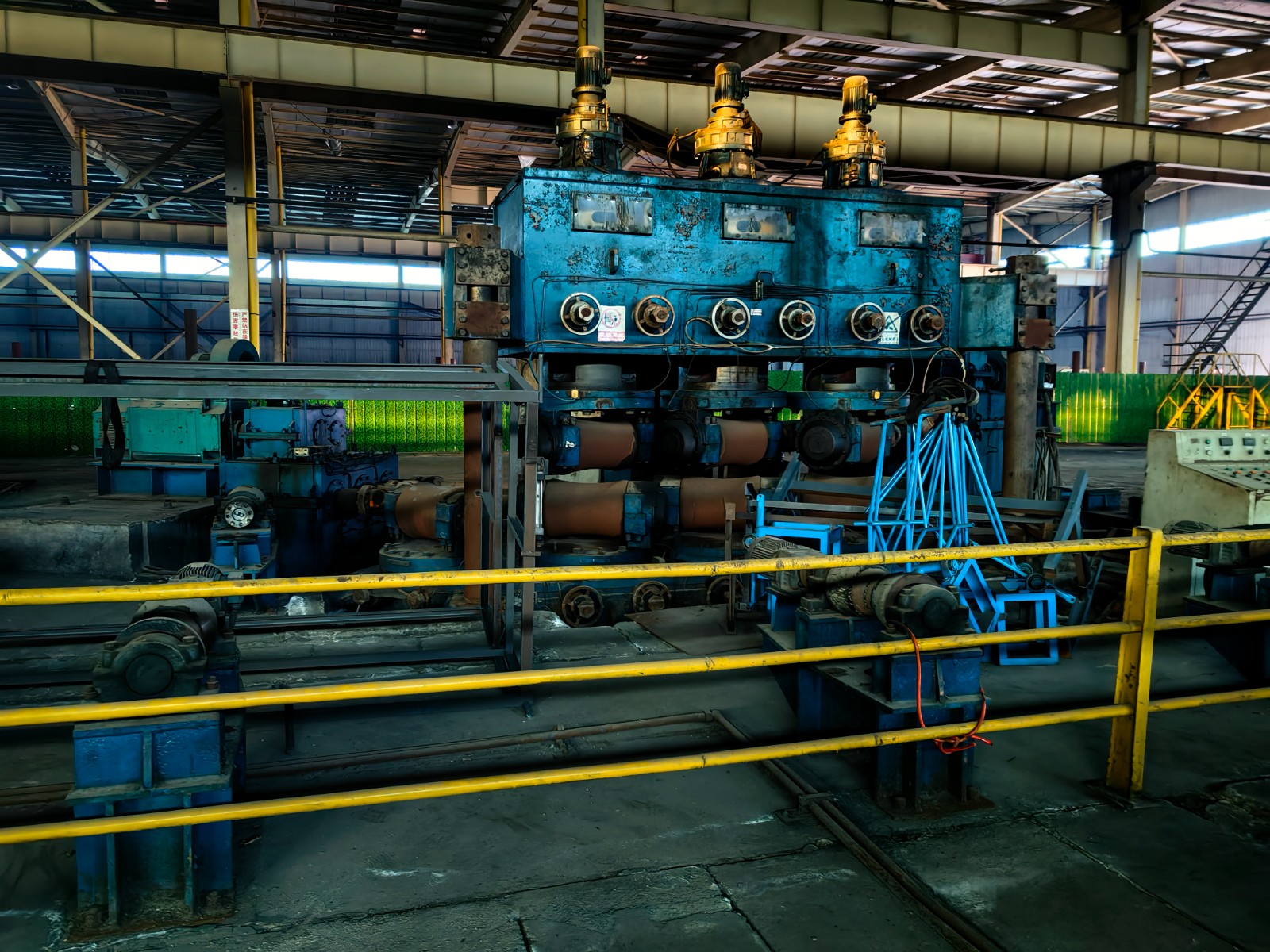

ERW Tube Mill

new ERW tube mill

written date: Feb 27th,2025 ,stock number:612- product description

- Technical Parameters

new machine is ready for sale.

This equipment is specially used for producingΦ10-Φ40mm,δ0.47-2.0mm high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe. The composition of equipment is from uncoiler to computer fixed length-cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

Applicable material:The material of steel strip is general carbon steelQ195,Q235,16Mn and etc hot rolled and cold-strip.

round pipe diameter: Φ10mm~Φ40mm

round pipe thickness: δ0.47mm~2.0mm

square pipe size: 10×10~30×30mm

square pipe thickness: δ0.47mm~2.0mm

Rectangular pipe size: 10×15~20×40mm

Rectangular pipe thickness: δ0.47mm~2.0mm

Rolling speed:30M/min~120M/min

Pipe length: 3M~8M

Applicable material:The material of steel strip is general carbon steel Q195,Q235,16Mn hot rolled,cold-strip steel and galvanized steel and etc.

NO. | Item | Value | Note |

1 | thickness | δ0.47~2.0mm | |

2 | width | 30~120mm | |

3 | O.D. | Φ600mm~Φ1800mm | |

4 | I.D. | Φ450mm~Φ550mm | |

5 | Maximum | ≤3000kgs |

Square pipe production mode: round changed into square.

production mode: continuous

Operation direction of the machine: left feeding or right feeding (determined by the technological arrangement of the user workshop)

Rolling bottom line: Around +760mm(Can be Customized according to the requirements from customer).

Welding method: high frequency induction welding,150KW

Rolling speed: 30-120m/min

Total power consumption of the production line:290KW,Voltage:380V/50HZ

craft process:

Raw material (steel strip) → uncoiling → shearing and end welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finishing tube

scope of supply: double side manual uncoiler, shear welder, cage accumlator,forming and sizing machine, cold saw, conveyor table, soild state HF welding machine 150kw

some foreign brands of this machine

Ac motor of equipment: Siemens Beide

Servo motor of cold saw: Yaskawa

Cutting motor of cold saw: siemens

Motion controller of cold saw:British TRIO

Inverter of cold saw:Yaskawa

Electrical components of cold saw: Schneider

If you want to quote or further information on this product, please fill out the form below.

Previous:new ERW tube mill

-

Used 12 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

Used 12 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

-

Used laboratory instrument for API pipes in Shanghai, China

Used laboratory instrument for API pipes in Shanghai, China

-

new ERW tube mill

new ERW tube mill

-

Used H beam production line

Used H beam production line

-

Used straightening machine

Used straightening machine

-

NAKATA 2006 used OD355mm ERW tubemill

NAKATA 2006 used OD355mm ERW tubemill

-

Used OD 20inch ERW tubemill in Shanghai, China

Used OD 20inch ERW tubemill in Shanghai, China

-

new ERW tube mill

new ERW tube mill

-

Used 26 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

Used 26 in ERW tube mill to make API pipes (SMS Meer) in Shanghai, China

-

Used hydro tester

Used hydro tester

-

Used OD 12inch ERW tubemill in Shanghai, China

Used OD 12inch ERW tubemill in Shanghai, China

-

Used end facing machine

Used end facing machine

-

Used 600x600x20mm DFT tubemill line in Shanghai, China

Used 600x600x20mm DFT tubemill line in Shanghai, China

-

used (4-12.7)xOD273mm ERW tubemill