Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

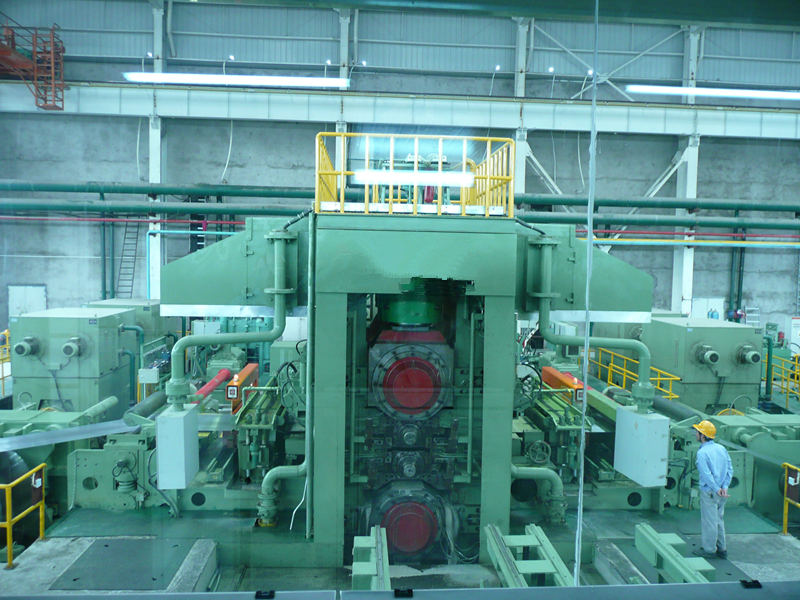

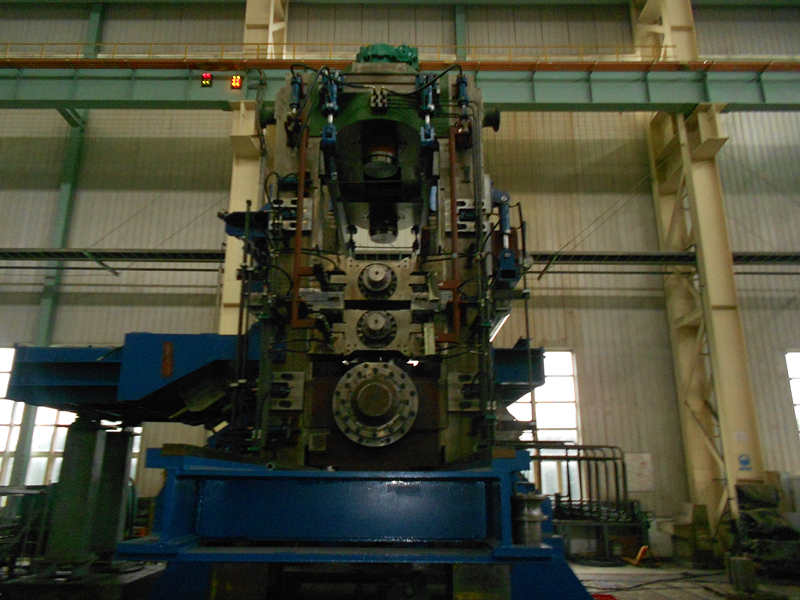

used cold rolling mill

Used (16-40)×2500mm leveling line

- product description

- Technical Parameters

A. technical specs:

1、material coil thickness:16-40mm;

2、material type: Q345、T600 steel strip;yield limit ǒs≤600Mpa;

3、leveling width:≤2500mm;

4、leveling roll material:42CrMo,quenching hardness HRC57~59;

leveling roll diameter:ф390,qty:7;

leveling roll gap:480mm;

leveling roll valid width:2600mm;

5、holding roll material:40Cr,quenching hardness HRC54~55;

holding roll diameter:ф390, qty: total 27 ;

6、top leveling roll valid lifting height:150mm;

7、quality requirement:flatness error:better than national standard

8、leveling speed:5-11m/ min;

9、pressing motor model:BWD16-43-15 kw 2 units;

pressing speed:15 mm/ min;

10、leveling main motor model:Z4-355-12-355kw 750r/min

11、adopts concentrate oil adding;

12、line color:based on buyer color sample;

13、center height:1000mm;

14、total weight:210 tons;

B. components:

1.leveling machine:composed of power part and main machine。

power part:Composed of power foundation, ZS1850 reducer, 280kw DC

frequency motor, distributor, coupling, clutch, connecting shaft and universal shaft and YWZ brake。

main machine:composed of leveling base, forge stand, forge bridge, forge sliding shaft base, top holder, top and bottom holding wheel base 3 units, top and bottom holding wheel 3 units, holding wheel adjust device, 7 leveling rolls, top leveling roll lifting and pressing device, 2 needle reducers, lubrication pumps 4 units and pressing ruler。

leveling roll shaft material 42CrMo, after forge —— process —— tempering —— process —— quenching —— process。

can control leveling speed by DC frequency motor。

it adopts power distributor, coupling cover connected to universal shaft, leveling rolls are with power, same line speed, to decrease friction and get better leveling quality。

leveling ends adopts 1 set of rolling machine bearing and 1 set of plain thrust bearing。

it adopts 3 sets of holding rolls, can adjust horizontally and vertically, and holding rolls bearings are seal bearings to prevent oxidation dander。

it adopts worm gear, while 2-level reducer pressing adjust torque big, pressure big, can adjust singly and at same time。

leveling roll adopts mid frequency quenching。

adopts leveling main shaft adopts concentrate oil adding。

thickness name | 14-40mm |

leveling rolls qty | 7 rolls |

leveling roll material | 42CrMo |

leveling roll diameter | φ390mm |

holding roll material | 40Cr |

holding rolls qty | 27个units |

reducer model | ZS1850 r=100 |

DC motor model power | Z4-315-32 280kw 750r/min |

pressing motor model、power | BWD16-43-15kw |

brake | YWZ-500/90 |

Total weight: approximate 210 ton

2.electrical system:power supply and distribution system:power:Ac380V 50Hz control voltage:Ac220V 50Hz

with control table and DC electrical box;

leveling machine can work backward, working rolls lifting by pressing motor, adjust motor can work singly or at same time, all electrical parts fit GB standard, with alarm stop button on control table, in red to protect operators。

C. lubrication:add oil for main gear box and distributor to bottom gear bottom(gear oil), change oil in per month after start working。

add oil to grease pit for reducer, change oil in per month after start working。

add lubricating grease(butter)for adjust worm and bearing。

add mixed oil(in winter: lubricating grease: engine oil= 1:2, in summer: lubricating grease: engine oil= 2:1) for leveling roll bearing and holding roll bearings, 3 times/shift

If you want to quote or further information on this product, please fill out the form below.

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

New 1450 skin pass in stock

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used 4 hi skin pass

Used 4 hi skin pass

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used roll grinder

Used roll grinder

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 4-hi 3-tandem AGC CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 1450 6-hi reverse CRM

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill