Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

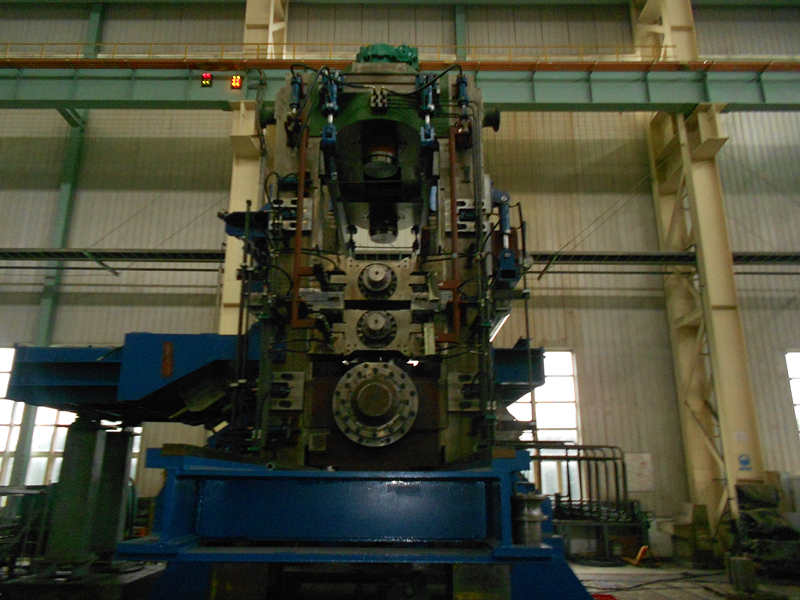

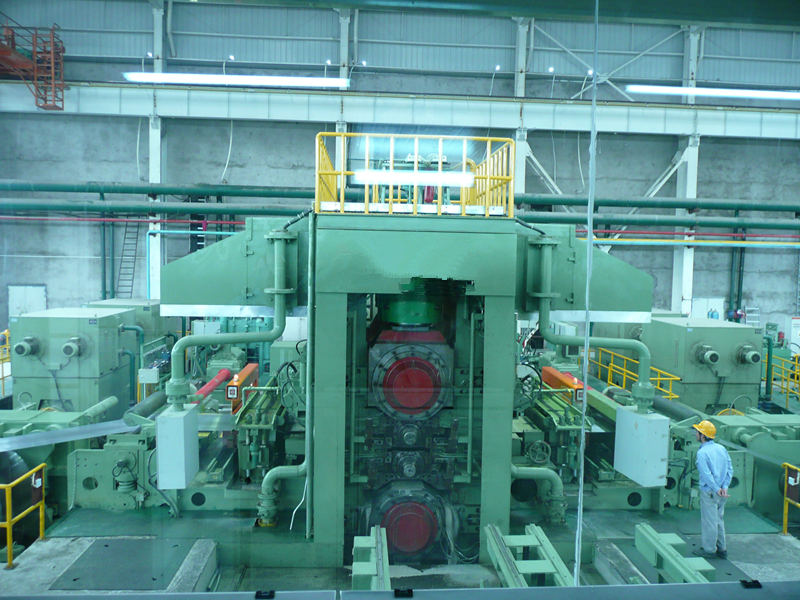

used cold rolling mill

Used 1450 6-hi reverse CRM

- product description

- Technical Parameters

A. main specs

1. hot rolling pickled steel coil

material type:Q195、Q215、Q235、08Al、silicon steel(Si≤2.4%)

mechanical performance

max yield strength:σs<325N/mm2

thickness:1.8~4.5mm silicon steel 2.0-2.5mm

width:800~1280mm

coil r(OD/ID):Φ610/Φ2000mm

max coil weight:25t

2. finished products

thickness:0.20~2.0mm

width:800~1280mm

coilr(OD/ID):Φ508/Φ2100mm

max coil weight:25t

thickness error: ±10μm(δ<0.5mm)

±2%δ(δ³0.5mm)

3. main technical specs

a) MAX rolling pressure:16000KN

b) MAX rolling torque:130KN.M

c) MAX rolling speed:900m/min

d) coil run through speed:18m/min

e) uncoiling tension:60KN(400m/min)

f) uncoiling speed:400m/min

g) coiling tension:160KN

h) max coiling speed:950m/min

i) working rolls size:Φ340~Φ300×1450mm (MC3)

j) middle rolls size:Φ430~Φ390×1450mm(MC3)

k) back up rolls size:Φ1200~Φ1050×1450mm(9Cr2)

l) house section size:60×72(cm)=4320c m2

m) uncoiler cone diameter:Φ560~Φ620mm(circle Φ610mm)

n) coiler cone diameter:Φ510~Φ485mm

o) side guiding rolls:Φ400×1450mm

p) guiding rolls size:Φ200×850mm

q) oil removal rolls size:Φ200×1450mm

r) working rolls max openness:20mm

s) working rolls bend pressure(single side positive/negative): 300/200KN

t) middle rolls single side bend pressure:430KN

u) middle rolls horizontal moving pressure:550/350KN

v) middle rolls horizontal moving range:225mm

w) hydraulic system pressure:31.5MPa

x) rolls bending, horizontal moving pressure:21MPa

y) normal hydraulic transmission working pressure:10Mpa

z) cooling media:emulsion

aa) craft lubrication flow:7500 L/min

bb) uncoiler motor:400KW

cc) coiler motors:1000KW´2´2(series)

dd) main rolling mill motors:1000KW´2´2(series parallel connection)

ee) emulsion recycle cooling lubrication:vacuum filter and air oil removing

ff) working type: reverse rolling

gg) products accuracy: h=0.2—0.5mm δ≤±5μ

h>0.5mm δ≤±1.0%h

straightness 25I

B. Scope of supply

no. | name | qty(unit) | brand | weigh (T) |

1 | coil loading car | 1 | maker | About 550tons |

2 | uncoiler | 1 | Maker | |

3 | leveling machine and hydraulic shear | 1 | Maker | |

4 | left coiler | 1 | Maker | |

5 | coil unloading car | 2 | Maker | |

6 | devices before mill | 1 | Maker | |

7 | 1450mm 6-hi CRM | 1 | maker | |

8 | movable covers | 1 | maker | |

9 | rolls changing car | 1 | Maker | |

10 | back up rolls changing machine | 1 | Maker | |

11 | devices after mill | 1 | Maker | |

12 | right coiler | 1 | Maker | |

13 | assistant coiler | 1 | Maker |

If you want to quote or further information on this product, please fill out the form below.

-

Used 4 hi skin pass

Used 4 hi skin pass

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used 1450 6-hi reverse CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used roll grinder

Used roll grinder

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 4-hi 3-tandem AGC CRM

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

New 1450 skin pass in stock

-

Used ⌀180/590 x 700 4-hi cold rolling mill