Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

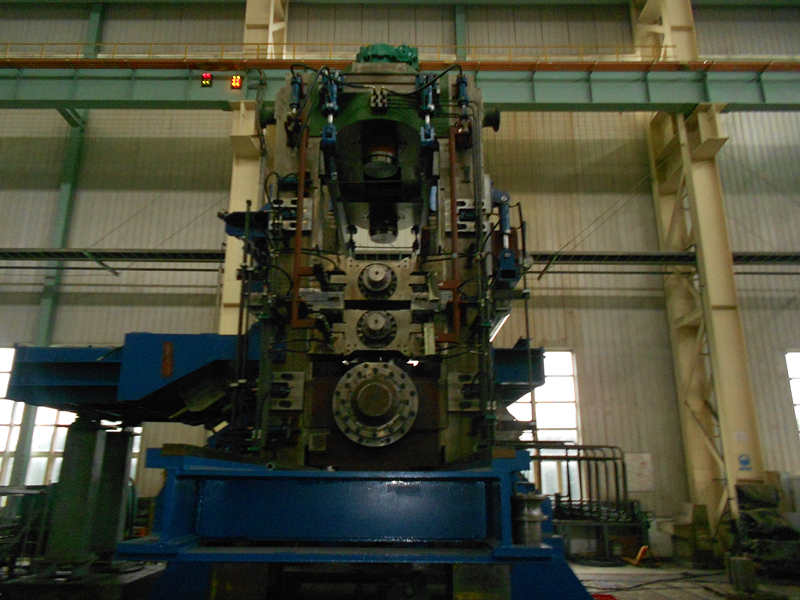

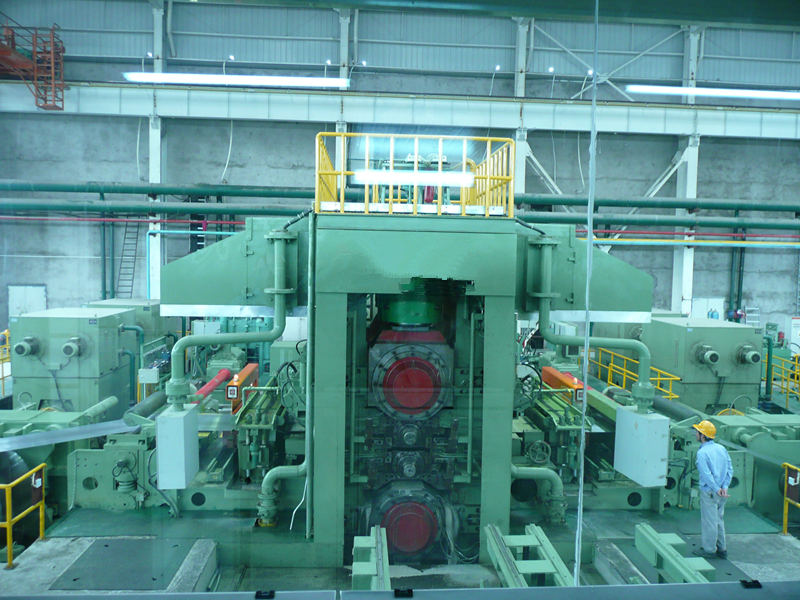

used cold rolling mill

used 1150 6-hi reverse CRM

- product description

- Technical Parameters

maker: china brand

A. main performance specs

material specs

material type: pickled hot rolling strip08A1、Q195、SPHC、SPHD,SPHE、STW、

low alloy and so on

mechanical performance:yield limit?S?360N/mm2

thickness: 2.0-3.5 mm

width: 700-1050 mm

coil ID: ?508/610 mm

coil OD: ?800-?1900mm

single unit max coil weight: ≤20kg/mm

coil weight: Max 22T

finished product

thickness: 0.15-1.2mm

width: 700-1050mm

coil ID: ?508mm

coil OD: ?800-?1900mm

coil weight: Max 22T

main technical specs

1. rolling mill

rolling mill model: 1150D

max rolling pressure: 8000KN

max rolling torque: 50KNm

rolling speed: 0~500~900m/min

cross speed: 18m/min

uncoiling speed: 360m/min

uncoiling tension: 50KN

coiling tension: 7.5~75~130KN

uncoiling cone diameter: Φ520/Φ460 mm (round Φ510mm)

coiling cone diameter: Φ508 mm/Φ488 mm (round Φ508mm)

working rolls dimension: Φ220 mm/Φ200×1150 mm

middle rolls dimension: Φ350 mm/Φ320×1100 mm

back up rolls dimension: Φ950 mm/Φ890×1050 mm

middle roll horizontal moving range: 150 mm

mouth open degree: 20mm

working rolls curve force: +150KN /-110KN

middle rolls curve force: +150KN

main transmission motor: 2×1600KW

coiler motor: 2×2×618KW

uncoiler motor: 316KW

pressing down type: hydraulic

craft lubrication media: elusion

craft lubrication flow: 6000l/min

mill working type: reverse rolling

uncoiling direction:left

uncoiler

cone:coil dismeter φ508/610mm

max speed:360m/min

tension:Max.50 kN

transmission motor power:316kW×1 台unit(DC)

coilers

cone:φ508mm

speed:≤900m/min. tension:Max.130 kN

transmission motor power:618kW×2 台units(DC)

B. components

mechanical devices

hydraulic system

electrical transmission system

PLC system

computer thickness control system

lubrication system

C. machine installing level

1. rolling mills,, uncoilers and coilers adopt SIEMENS digital DC speed control, SCR power supply and PLC control.

2. hydraulic pressing down, computer thickness auto control(AGC). hydraulic AGC system has function of constant roll seam, constant rolling force, thickness monitor and pre-press auto control.

3. mill has controls of pressing bias control, working rolls positive curving, middle rolls positive/negative curving, middle rolls horizontal moving set and division cooling.

4. uncoiler has CPC auto center function.

5. electrical system has overload protection, strip brake protection and alarm stop funtions; main mills and coilers have

coil end auto sp?eed reduce and accurate stop function, coiler has turn qty memory function.

6. mill speed closed loop control, uncoiler and coiler speed/tension closed loop control, digital display.

7. rolling mills bearings and speed detect rolls bearings oil mist lubrication.

8. mill craft linkage and error alarm adopts PLC program control.

If you want to quote or further information on this product, please fill out the form below.

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

New 1450 skin pass in stock

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 4-hi 3-tandem AGC CRM

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 4 hi skin pass

Used 4 hi skin pass

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used roll grinder

Used roll grinder

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill