Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

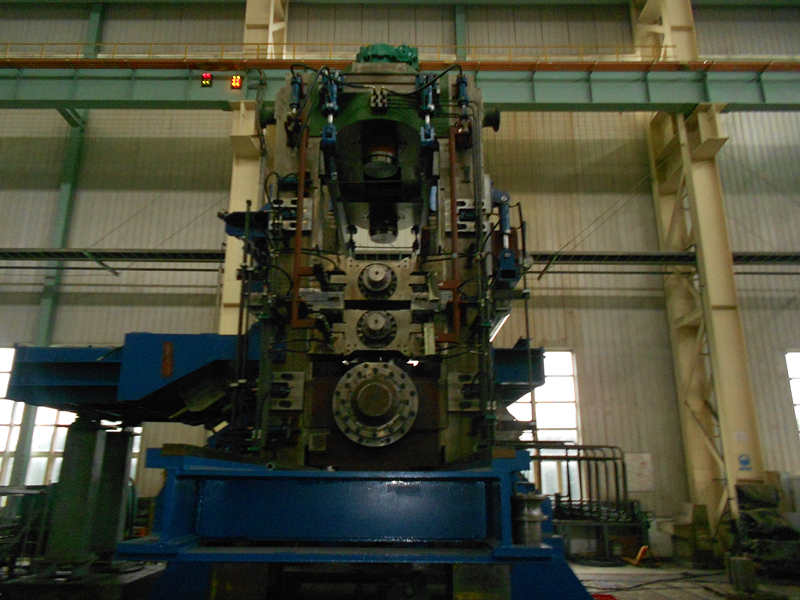

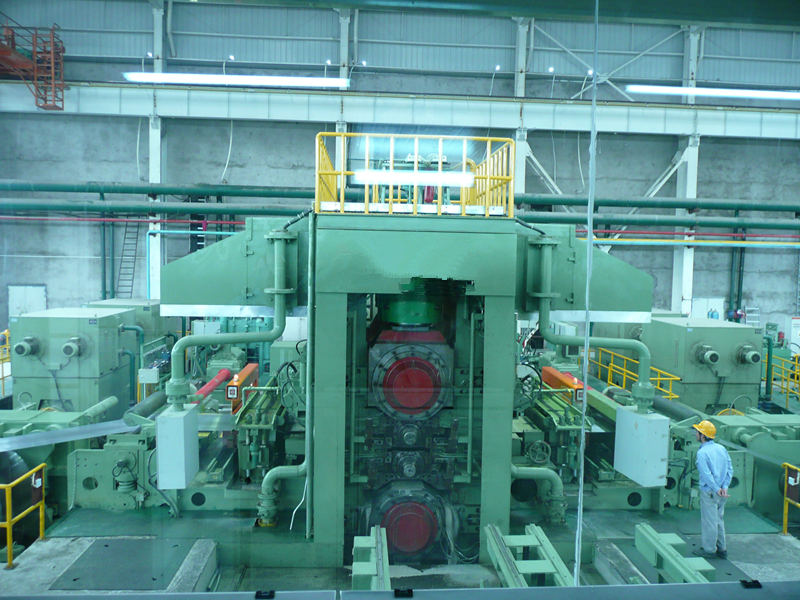

Used 1450 6-hi reverse CRM

- product description

- Technical Parameters

A. technical specs

1. material spec:hot rolling pickled steel coil or annealed cleaned steel coil.

material type:Q195、Q215、Q235、08Al、20、SPHC、SPHD、SPHE。

yield strength: бs≤360 N/mm2, бb≤610 N/mm2

thickness: 1.2~4.0mm

width: 900~1300mm

coil ID: Φ610mm

coil OD: maxΦ2100mm

max coil weight: 26t

2. finished product spec:

thickness: 0.25~1mm

width: 900~1300mm

coil ID: Φ610mm

coil OD: maxΦ2100mm

max coil weight: 26t

3. finished product accuracy:

thickness error:±10 μm (d<0.5mm)

±2% d (d≥0.5mm)

straightness: 10I-15I

4. equipment main specs:

max rolling pressure: 18000kN

max rolling torque: 135kN·m

rolling speed: 0~468~1000 m/min

coil run through speed: 18m/min

max coiling speed: 1050m/min

uncoiling pressure: 80~8 KN

coiling pressure: 170~17 KN(Ⅰ挡level V<640 m/min)

working rolls size: F400~F370×1450

middle rolls size: F450~F415×1450

back up rolls size: F1250~F1190×1350

uncoiler cone diameter:Φ620~Φ560㎜(circle Φ610㎜)

coiler cone diameter:F595~ F610 mm(circle F610 mm)

working rolls max open mouth(new rolls): 20mm

working rolls positive bend pressure(single side):375/280 KN

middle rolls positive bend pressure(single side) : 450kN

middle rolls horizontal moving range: 200mm

hydraulic transmission system pressure: 10 Mpa

craft lubrication flow: 8000L/min

main motors power:

main rolling mill motors:DC1250 KW×4(series parallel connection)

coiling motor:1000KW´2/units´2(series)

uncoiler motor: DC 560KW

B. Scope of supply

a. mechanical part

name | qty | weight(Kg) | ||

1 | coil loading car | 1 | 11200 | |

2 | uncoiler | 1 | 26070 | |

3 | leveling machine | 1 | 17671 | |

4 | coiler before mill | 1 | 29250 | |

5 | unloading car | 2 | 18200 | |

6 | device before mill | 1 | 20940 | |

1) | turn and guiding device before mill | 1 | 4200 | |

2) | speed detector(option) | 1 | ||

3) | tension detector | 1 | 1300 | |

4) | thickness gauge holder | 1 | 890 | |

5) | vacuum oil removal device | 1 | 6100 | |

6) | center guiding device | 1 | 1650 | |

7) | foundation | 1 | 6100 | |

8) | foundation, pipes | 700 | ||

7 | 1450 6-hi reverse CRM | 1 | 361700 | |

8 | device after mill | 1 | 26990 | |

1) | vacuum oil removal device | 1 | 6100 | |

2) | thickness gauge holder | 1 | 890 | |

3) | strip shape tension gauge(without strip shape checking rolls) | 1 | 510 | |

4) | speed detector | 1 | ||

5) | disc shear | 1 | 4800 | |

6) | turn and guiding device after mill | 1 | 4200 | |

7) | static electricity oil remover rail foundation(without static electricity oil remover) | 1 | 1500 | |

8) | foundation | 1 | 8200 | |

9) | foundation, pipes | 700 | ||

9 | right coiler | 1 | 30640 | |

10 | rolls changing device | 1 | 60680 | |

1) | working rolls and middle rolls changing machine | 1 | 42450 | |

2) | back up rolls changing machine | 1 | 11310 | |

3) | movable covers | 1 | 6920 | |

11 | coiling assistant machine | 1 | 11800 | |

12 | motor foundation, control box | 18250 | ||

total | 63391 | |||

b. fluid equipments

name | qty | remark | |

1 | hydraulic pressing control system | 1set | |

1.1 | hydraulic power station | 1unit | |

1.2 | control valve station | 1unit | |

1.3 | Energy storage filter device | 2units | |

1.4 | pressing oil cylinder device | 2units | |

2 | balance, roll bending, horizontal moving hydraulic control system | 1set | |

2.1 | hydraulic power station | 1unit | |

2.2 | control valve station | 2units | |

2.3 | horizontal moving oil cylinder device | 4units | |

3 | uncoiling CPC center control system | 1set | |

3.1 | photoelectric detection adjusting holder | 1unit | |

3.2 | CPC electrical cabinet | 1unit | |

3.3 | control valve station | 1unit | |

3.4 | uncoiling center cylinder | 1unit | |

4 | hydraulic transmission control system | 1set | |

4.1 | hydraulic power station | 1unit | |

4.2 | control valve station | 6units | |

5 | oil lubrication system | 1set | |

5.1 | oil lubrication station | 1unit | |

5.2 | electrical operation box | 1unit | |

6 | air-oil lubrication station | 1set | |

7 | craft lubrication and rolls cooling system | 1set | |

7.1 | oil tank device | 1set | |

7.2 | 净液输送站clean fluid convey station | 1套set | |

7.3 | waste fluid convey station | 1set | |

7.4 | vacuum filter | 1unit | |

7.5 | emulsion pressure adjusting and beside road device | 1set | |

7.6 | emulsion temperature controller | 1set | |

7.7 | emulsion distributing valve device | 2sets | |

7.8 | cooling nozzle bridge device | 1set | |

7.9 | original fluid device | 1set | |

8 | vacuum oil removal system | 1set | |

9 | pneumatic system | 1set | |

10 | middle pipes | 1set | seller design, buyer supply |

c. electrical devices

no. | name | qty | main producer | core elements | remark |

1 | mail mill electrical transmission device | 4sets | tianchuan | SIEMENS | rated 3000A |

2 | coiler before mill electrical transmission device | 2sets | tianchuan | SIEMENS | rated 2500A |

3 | coiler after mill electrical transmission device | 2sets | tianchuan | SIEMENS | rated 2500A |

4 | uncoiler motor electrical transmission device | 1set | tianchuan | SIEMENS | rated 1200A |

5 | tension rolls DC coiler before mill electrical transmission device | 2sets | tianchuan | SIEMENS | rated 30A |

6 | computer system | 1set | ADVANTECH | ||

7 | PLC device and monitor | 1set | SIEMENS S7400 | ||

8 | AC control system | 1set | tianchuan | china made Schneider | |

9 | relay and operation cabinet | 1set | tianchuan | ||

10 | power supply device | 10sets | SIEMENS | ||

11 | big DC motor | 9units | xiangtan | china made | |

12 | Oil-immersed rectifier transformer | 4units | china made | ||

13 | thickness gauges | 2units | imported | to be confirmed | |

14 | tension gauge | 2sets | ABB | ||

16 | speed detector | 2sets | BEIISTAR | option |

C. remark: this machine was produced in 2011, started working in 2011.10 and stopped working in 2016.6, it’s located in user factory now.

If you want to quote or further information on this product, please fill out the form below.

-

Used 1450 6-hi reverse CRM

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used 4 hi skin pass

Used 4 hi skin pass

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used roll grinder

Used roll grinder

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used 4-hi 3-tandem AGC CRM

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

New 1450 skin pass in stock

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill