Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

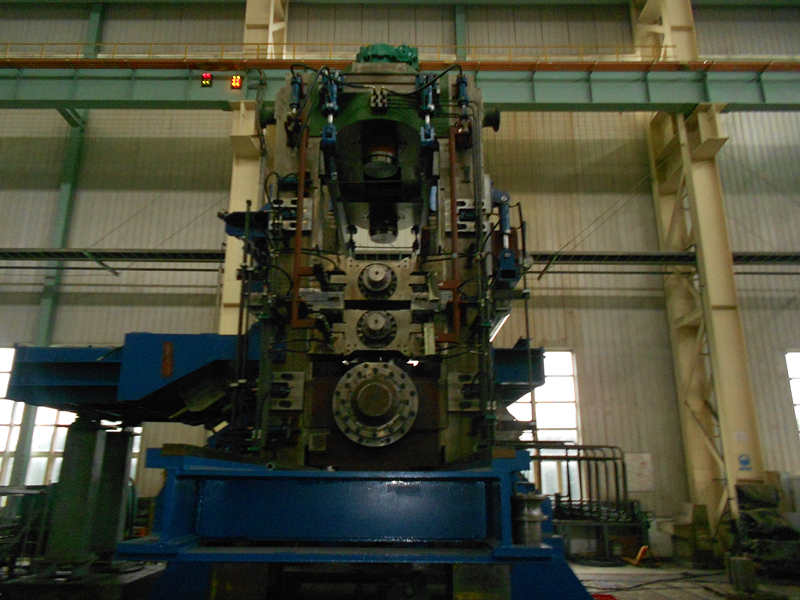

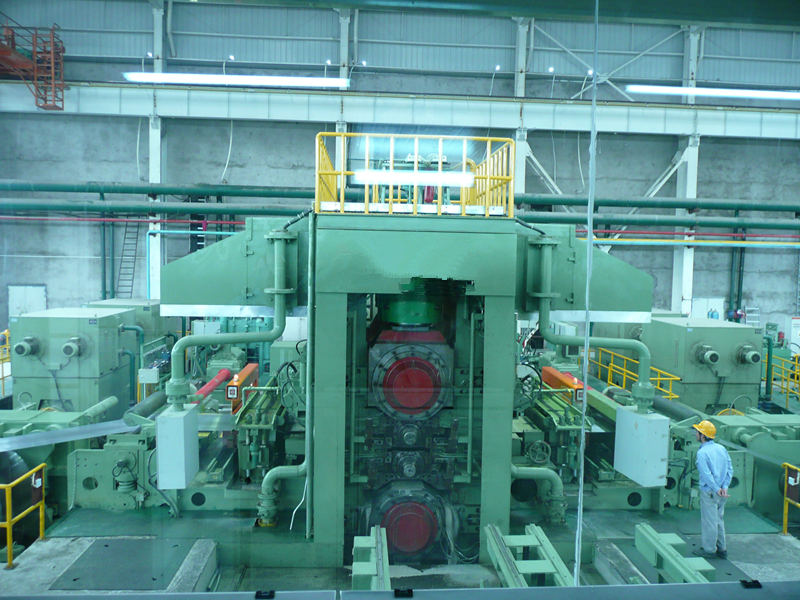

Used 4-hi 3-tandem AGC CRM

- product description

- Technical Parameters

Used 4-hi 3-tandem AGC CRM

for rolling of low carbon steel coil

AGC pressing

coil width: 550mm

machine is half made

main specs

2.1 material: hot rolling coil after pickling(after trimming or not)。

2.1.1 material type: low carbon steel、Silicon Steel (Silicon<1.8%)。

grade: Q195、Q215、Q235、610

2.1.2 thickness: 3.0~2.5mm

2.1.3 width: 400~550mm

2.1.4 coil ID: φ508mm

2.1.5 coil OD: φ1100~φ1600 mm

2.1.6 max coil weight: 8t

2.2 finished product:

2.2.1 thickness: 0.5~1.2mm

2.2.2 width: 400~550mm

2.2.3 coil ID: φ508mm

2.2.4 coil OD: φ1000~φ1600mm

2.2.5 max coil weight: 8t

2.3 line specs:

2.3.1 max rolling force: 5000 kN

2.3.2 max rolling speed: 250 m/min

2.3.4 max uncoiling speed: 50 m/min

2.3.5 max recoiling speed: 250m/min

2.3.6 recoiling tension: 10~40kN

2.4.7 working roll size: φ185/φ170×650mm

2.3.8back up roll size: φ550/φ520×620mm

2.3.10cone diameter:(expanding/shrink):φ508/φ495mm

2.3.11stand column section: 320*420

2.3.12working roll min open mouth: 20mm

2.3.13working roll bending force(single roll single side): 80kN

2.3.14common hydraulic system pressure: 10MPa

2.3.15 balance roll bending system pressure: 15MPa

2.3.16 thread speed: 30 m/min

2.4.17 pressing system pressure: 25Mpa

main rolling motors: N=600KW total 3 units

recoiling motor: N=250kW 1 unit

scope of supply:

1. mechanical devices:

a. coil entry car

b. uncoiler(hydrauic expanding)

c. leveler and pressing arm

d. coil end shearing machine

e. welding plat form

f. platform before rolling: including vertical roll center device, turning roll and base

g. cold rolling mill(AGC pressing)

g.1. rail base

g.2. rolling stands

g.3. pressing device

g.4. working rolls

g.5. working rolls bearing and bearing house

g.6. working roll bending system

g.7. back up rolls

g.8. back up rolls bearing and bearing house

g.9. back up roll balance system

g.10. rolls axis direction lock system

g.11. emulsion spray device

g.12. taking shaft holder

h. tension tables: 2 units

i. exit craft plat form

i.1. oil removing rolls

i.2. tension rolls

i.3. turning rolls

j. recoiler

k. run out car

l. roll exchange car: for changing working rolls and back up rolls

m. taking shaft device

n. composite redcuer

o. motor coupling

p. arm holding

2. fluid equipments

a. hydraulic system

b. lubrication system

c. emulsion system

If you want to quote or further information on this product, please fill out the form below.

Previous:Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Next:Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 4 hi skin pass

Used 4 hi skin pass

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

Used 1450 6-hi reverse CRM

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used roll grinder

Used roll grinder

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

New 1450 skin pass in stock

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill