Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

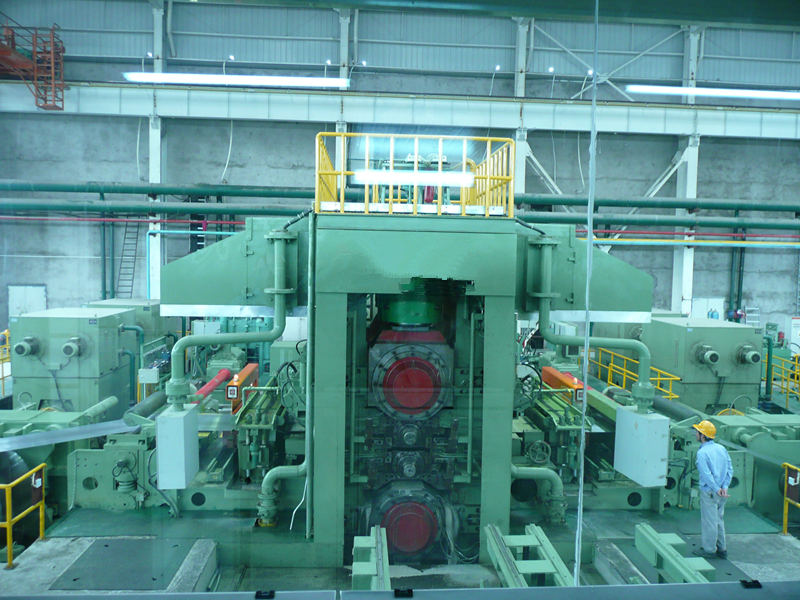

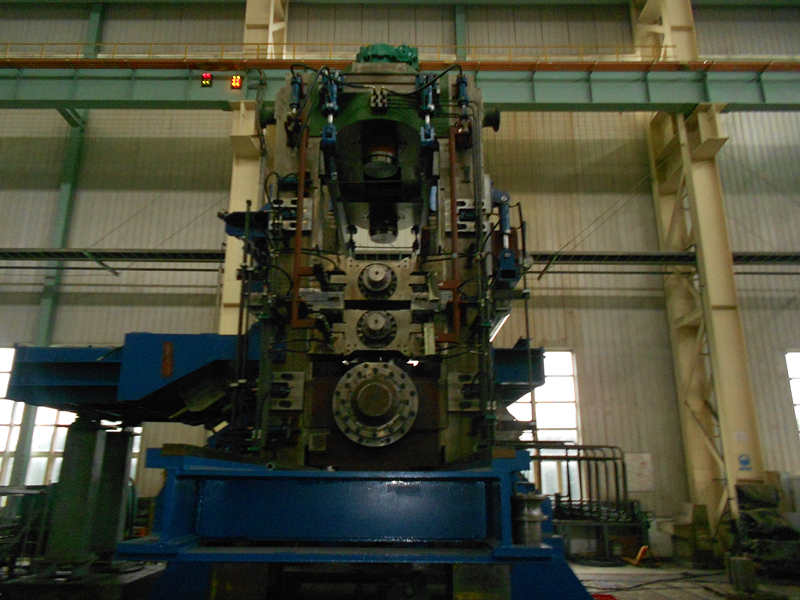

New 1450 skin pass in stock

- product description

- Technical Parameters

Technical specs of 1450 skin pass

made in 2014, not used

A. craft specs:

1. material type: low carbon steel

2、material size:(0.2~1.5)×1250 mm

3、max rolling force:7000KN

4、coin ID and OD:φ508/φ1600mm

5、rolling speed:180m/min

6、coil weight:(max)≤18.0T

7、recoiling tension:≤50KN

8、leveling type:dry and humid

9、feeding direction:

B. specs

1、main machine spec:φ420/φ840×1450 4-roll leveling machine

transmission: working rolls

Composed of pressing device, stand, rolls, balance device, main transmission and roll changing device.

a、hydraulic pressing device(hydraulic APC system)

adopts APC hydraulic pressing control

pressing oil cylinder: made of alloy

Function: pressure control and display

b. rolls

working rolls:φ420×1450mm material type 9Cr2Mo

bearing: FC487220 for rolling mill

back up roll:φ820×1400mm material 9Cr2Mo

bearing:FCDP100136450 for rolling mill

bearing lubrication type: dry oil

back up roll balance type: hydraulic

rolling line standard height:+950mm

c. stand

house column section:420×500mm stand material:ZG270-500

whole processing, manual shovel and with window sliding plate

rolls axial direction location type: pressing plate type

d. main transmission

bottom working roll single shaft transmission

main motor:Z4-355-42 400KW 600/1300rpm 440V

main reducer:ZLY450

universal shaft:SWC350 cross metallurgical universal shaft

e. before and after mill device

with shape rolls at entrance and holding rolls at exit。

f. Roll changing device: hydraulic, with changing car for working roll changing and bracket between top and bottom back up rolls

2. “S” roll device before and after mill

top S roll motor:Z4 series, 200KW,

bottom S roll motor:Z4 series, 132KW,

top and bottom S roll reducer:ZLY280 hard face reducer

top and bottom S roll size:φ900×1450mm

pressing coil size:φ160×1450mm

3、shearing and pinching device:

with function of assisting feeding, shearing and pinching as following:

after guiding plate swing, shovel plate reaches out to guide coil into 2-roll pinching device by holding rolls, with help of rubber pressing plates and guiding plate, coil head pass S roll, then through guiding leveling machine roll seam and forward into recoiler and pinched and recoiled。

4、uncoiler(with EPC system)

type: hydraulic cone expanding, fluctuation, auto centering

cone size:φ508×1450mm expanding range 30mm

motor:Z4-315-41 160KW 400/1200rpm

reducer: self made

attachments: hydraulic coil pressing device, assistant holding, hydraulic pressing rolls and run out car

5、recoiler

type: hydraulic cone expanding,

cone spec:φ508×1450mm expanding range 30mm

motor:Z4-355-42 250KW 400/1200rpm

reducer: self made, oil lubrication

attachments: hydraulic pushing device, assistant holding, hydraulic pressing rolls and run out car

6、hydraulic station

with cooler, energy saver, point pressure gauge, unloading device, overflow valve, filer, level display and system pressure control functions。

7、lubrication oil station:for lubrication and cooling of bearing in reducer。

composed of oil feeding pipe, oil return pipe, pump, motor, cooling, filter, valve and gauge。

8、electrical system:

it adopts imported SIEMENS 6RA70 DC driver。

C. scope of supply:

1、run out car

2、uncoiler

3、shearing and pinching device

4、S roll device before mill

5、tension stand

6、shape roll at entrance

7、main stand(include rolls, hydraulic APC system and power system)

8、balance roll at exit

9、tension stand

10、S roll device after mill

11、shearing and pinching device

12、recoiler

13、roll changing device

14、foundation bolts

15、lubrication oil system

16、hydraulic system

17、electrical system

D. craft flow entry car

![]()

uncoiler

![]()

shearing and pinching device

![]()

S roll device before mill

![]()

shape roll

![]()

main rolling mill

![]()

balance roll

![]()

S roll device after mill

![]()

shearing and pinching device

![]()

recoiler

E. scope of supply of buyer:

pipes and wire;

foundation building;

pats and wires;pipe and joints for hydraulic station, oil station and craft lubrication station;

installation of mill(mechanical, hydraulic and electrical devices);(seller will send technician to help)

hydraulic oil, emulsion, coil, gear oil, lubrication oil;grease for test running and thickness gauge

AC electrical power:

spare parts

seller will provide brand, model or drawing of spare parts for buyer purchasing

If you want to quote or further information on this product, please fill out the form below.

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used 4-hi 3-tandem AGC CRM

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

Used roll grinder

Used roll grinder

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used 4 hi skin pass

Used 4 hi skin pass

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

Used 4-hi skin pass

Used 4-hi skin pass