Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

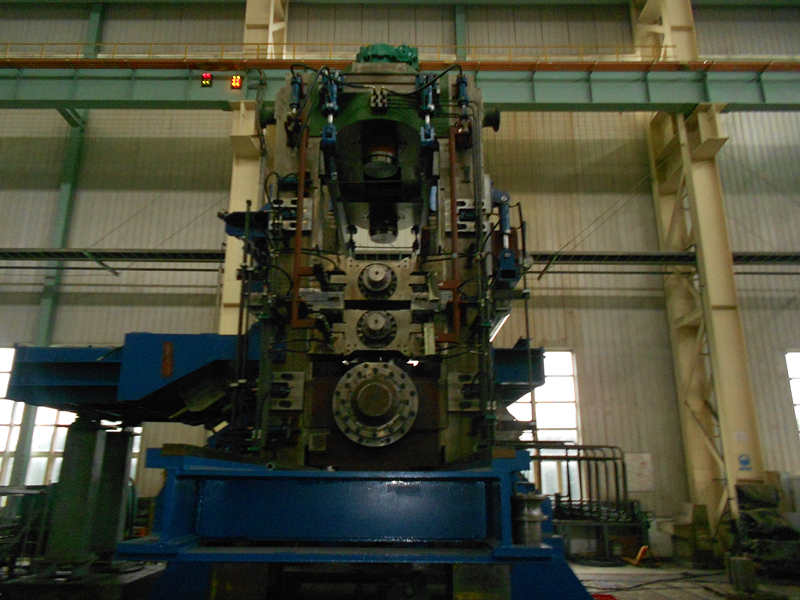

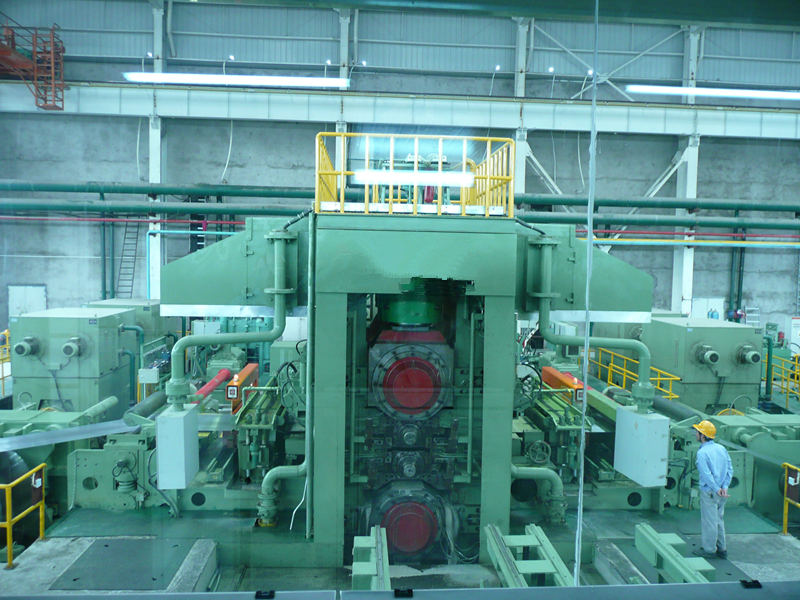

used 450 4-hi 3-tandem CRM

- product description

- Technical Parameters

A. Product information

maker: china brand

- Rolling requirement

a. coil material type:carbon steel

b. coil specs:thickness 2.75mm, width 400mm, coil ID:Φ508㎜, max coil weight:3500kg

c. finished product specs:≤0.9*400, coil ID:Φ508㎜, max coil OD:Ф1600mm, max coil weight:3500kg

d. rolling pressure P≤300T

e. rolling speed: design speed 180m/minute, normal working 150m/minute

- rolling technological process

accumulator: Ф330-360 hydraulic expanding loading rack, hydraulic shear and welder, spiral accumulator

1#tandem ---2#tandem ---3#tandem ---coiler

- components and specs

a. 1#tandem, 2#tandem, 3#tandem

b. 1#tandem spec: Ф175/Ф450X450mm working rolls transmission, 1#tandem, 2#tandem spec: Ф145/Ф450X450mm back up rolls transmission

c. pressing part:

1. pressing motor: Y 11KW*2. 6级

2. high speed worm gear box: WS170,i=41;center distance A=170mm

3. low speed worm gear box:double enveloping worm gear,center distance A=315mm,Mn=12 mm,i=40

4. pressing screw: Ф160X6 pressing speed:0.05mm/s

5. pressing box body adopts cast iron

d. stand

1. 2 closed houses,column section area:250X350mm, ZG35

2. window sliding plate, wholistic processing,manual shovel

3. craft plat form, thickness gauge rack, tension rolls

e. rolls part:

1. 1#tandem, working rolls shaft diameter X rolls surface width:Ф175X480 mm material type 86GrMoV7, compound needle roller bearing 2 functions

2. 2#tandem, 3#tandem, working rolls shaft diameter X rolls surface width:Ф145X480 mm material type 86GrMoV7, compound needle roller bearing 2 functions

3. back up rolls shaft diameter X rolls surface width:Ф450X450 mm material type 9Gr2Mo, bearing: FCD

For rolling mill only

4. bearing lubrication type: dry oil lubrication

5. back up rolls balance type:hydraulic balance

6. rolls changing type:hydraulic changing

f. main transmission part

1. main motor model: Z4,power:400kW

2. main reducer: ZLY400

3. Herringbone gear box:1#tandem,center distance A=230mm,2#tandem, 3#tandem, center distance A=690mm

4. reducer lubrication:thin oil lubrication

5. transmission shaft:universal shaft, 1#tandem, SWC220, 2#tandem, 3#tandem, SWC280

6. foundation:2 parts(part 1: motor, reducer, 2 box, part 2: stand)

g. expanding coiler: rectangular pyramid hydraulic coiler

1. cone diameter Φ508mm*550

2. expanding amount: 20mm

3. hydraulic pushing, hydraulic car, hydraulic expanding, hydraulic cylinder diameterФ320

4. max coil weight ≤3500kg

5. coiling tension ≤3500kg

6. main motor model: Z4,power:185kW

7. reducer: ZQ750

h. craft lubrication device:(prepared by buyer)

i. hydraulic system controlled by 1 hydraulic station,

function:energy accumulator,electro connecting pressure gauge,Unloading device, filter device, liquidometer and system pressure control。

j. thickness gauges: (prepared by buyer) 1set

k. tension gauge:

With 1 ton tension gauge 2untis, max tension 5 tons, max coiling tension 3 tons, to ensure each stand flow/s constant equal tension.

l. Electrical control system: adopts EURO 590 system(Two bridge four quadrants weak magnetic speed control), relay control system use PLC, need 8 I/O points, communicate with module digital circuit, has A/D,D/A transfer module, tension adjusting, coiling controlled by constant tension with coil diameter changing, there’s operation boxes at stands, can show current, speed, tension and thickness, and simple thickness auto control function.

If you want to quote or further information on this product, please fill out the form below.

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 4 hi skin pass

Used 4 hi skin pass

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used 4-hi skin pass

Used 4-hi skin pass

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

New 1450 skin pass in stock

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used roll grinder

Used roll grinder

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used 4-hi 3-tandem AGC CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)