Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

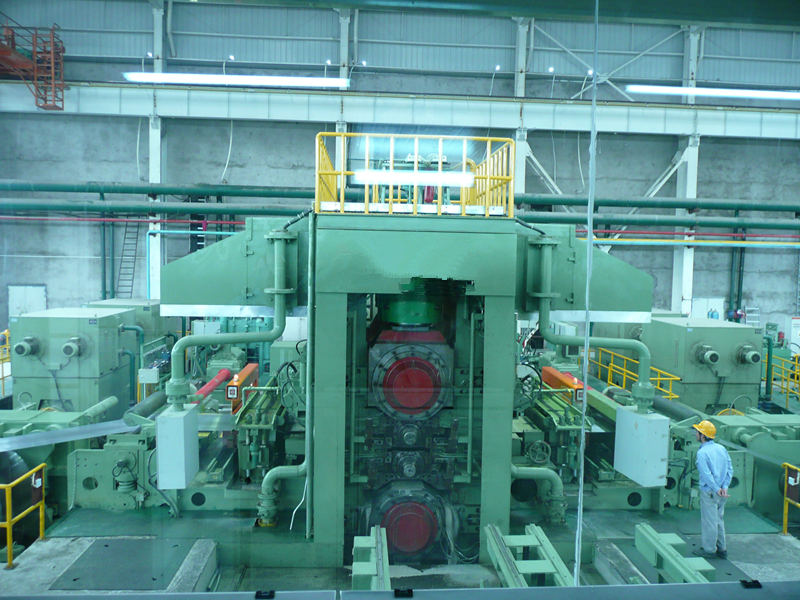

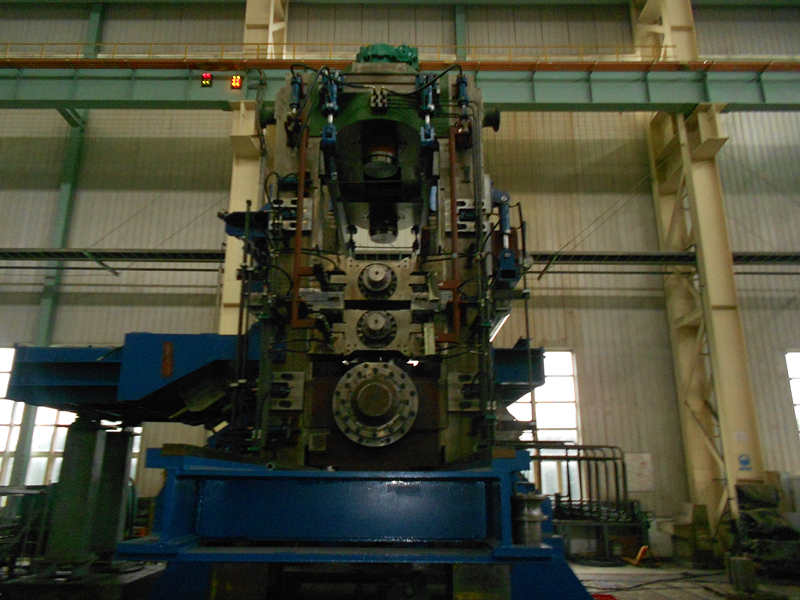

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

- product description

- Technical Parameters

A. 轧制条件rolling requirements:

材质material type:不锈钢stainless steel 201

进料厚度material thickness:≤3.0mm 进料宽度material width: ≤1000mm

成品厚度product thickness:≥0.25mm 成品宽度product width: ≤1000mm

轧制速度rolling speed:设计速度design speed V≤230m/min(负荷运转under load working speed 210m/min)

轧制压力rolling pressure:P≤1400t

B. 设备配置equipment compositions:

a. 主机main frame: Ф190 /Ф900×1180四辊AGC可逆冷轧机

Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

(1)、压下装置pressing down device:伺服油缸天津尤瑞纳斯servo oil cylinder made in tianjin

(2)、机架装配stand compositions:

1.两片闭合牌坊2 closed houses(立柱截面尺寸column section area:500×600㎜);

2.上下支承辊系为液压平衡top and bottom back up rolls are hydraulic balance,上工作辊液压抬辊top working rolls are hydraulic lifting;

3.工作辊辊缝开口高度working rolls seam open mouth height≤20㎜,以便穿带钢in order to enter coil;

4.配前、后托辊、测厚仪、液压式压紧装置及液压式挤干工艺台架with front and rear holding rolls, thickness gauge, hydraulic pressing down device and hydraulic squeeze plat form;

5.进口方向为单边可调滚轮式进料导位装置single side adjustable wheel entering guiding device at entrance side;

6.传动底座及整套基础螺栓、机架平台transmission foundation, whole set foundation bolts and stand plat form;

7.QNT-2型测厚仪 thickness gauges 二台2 pieces(用户自备supplied by customer);

(3)、轧辊装置rolls:

1.工作辊径working rolls diameter×辊面宽度rolls surface width Ф190×1180㎜

材质material type:9Cr2Mo

轴承采用滚动轴承 adopts rolling bearings

2.支承辊径back up rolls diameter×辊面宽度roll surface width Ф900×1150㎜

材质material type:9Cr2Mo

轴承采用bearings are FCDP106156570

3.润滑方式lubrication type:油气润滑air-oil lubrication

4.换辊方式rolls changing type:液压换辊hydraulic changing(配换辊轨道with changing guide rail),工作辊液压换辊working rolls hydraulic changing

(4)主传动main transmission:

1.传动方式transmission type:支承辊传动back up rolls transmission

2.主电机main motor:Z630-4A N=780KW 二台2 pieces n=280/850r/min(锡杉电机Xishan motor)

3.人字齿轮箱Herringbone gear box:复合齿轮箱compound gear box (配润滑油路管道with lubrication oil pipes)

5.十字式万向接轴cross cardan shaft:SWC490(伸缩型stretching type)万向液压抱轴装置 cardan hydraulic shaft hugging device

b. 液压涨缩开卷机设备配置hydraulic expanding uncoiler configuration:

开卷形式uncoiling type:开卷方向为上开卷uncoiling direction is upward,开卷机由卷筒、本体、底座、压辊、小车等主要部件组成composed of cone, main body, foundation, pressing rolls and trolley.

卷筒由四块扇形板,主轴组成。 带动扇形板移动实现卷筒的涨缩。涨缩缸有旋转给油器供油;开卷机减速箱体为焊接结构 ;底座为焊接 ;压辊由压辊支架、压辊(包胶)部件和液压缸组成,压辊支架为焊接结构,固定在开卷机箱体上。Cone composed of 4 fan plates, rotating oil provider give oil for expanding cylinder, reducer box is welded, pressing rolls composed of rack, pressing rolls and hydraulic cylinder, fixed on uncoiler body.

卷筒尺寸cone dimension:Ф490-Ф518×1200mm

电机motor:Z4-315-42 N=315KW n=750/1600r/min (锡杉电机Xishan motor)

减速机reducer:850

最大卷重max coil weight:20T 最大卷径max coil diameter:φ1800㎜

小车进出液压马达 trolley driven by hydraulic motor,升降油缸 lifting oil cylinder

三辊无动力矫平3-roll powerless leveling:辊rolls Ф160×1180mm

上辊液压动作top rolls hydraulic actions

c. 实芯卷取机solid coiler 二台 2 pieces

1.卷筒尺寸cone dimension:Ф500×1180mm

2.电机motor:Z630-4A N=830KW n=280/850r/min (锡杉电机Xishan motor)

3.减速机motor:ZLY710 (泰隆Tailong)

4.卷取张力coiling tension:≤20T 最大卷重max coil weight:20T 最大卷径max coil diameter:φ1800㎜

5.压辊装置上压式rolls pressing device top pressing type(包胶encapsulation)

d. 机组液压站 hydraulic station

1.中压11MPa 一台 1 piece of middle pressure 11MPa;

2.冷凝器condenser、蓄能器energy saver、压力表pressure gauge、三级过滤3-level filter、泄荷装置unloading device、溢流阀overflow valve、系统压力分节控制能力system pressure control function。

e. 稀油润滑站oil lubrication station:125L/min 一台 1 piece

(供轧机及卷取机减速箱、人字齿轮箱等齿面及轴承处润滑lubrication for rolling mill, coiler reducer, Herringbone gear and bearings)

f. 电控系统electrical control:远境remote

采用西门子二桥四象限弱磁调速装置,模拟恒张力控制方法。继电系统控制,采用可编程序控制PLC。电流、电压及有关参数仪表直观显示。It adopts SIEMENS 2-bridge 4-phase weak magnetic adjusting device, simulation constant tension control method. Relay system control, with programmable PLC (Siemens). Current, voltage and other parameters display on instruments.

If you want to quote or further information on this product, please fill out the form below.

Previous:Used (16-40)×2500mm leveling line

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used roll grinder

Used roll grinder

-

Used 1450 6-hi reverse CRM

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

New 1450 skin pass in stock

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

Used 4-hi 3-tandem AGC CRM

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used 4 hi skin pass

Used 4 hi skin pass

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM