Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

used cold rolling mill

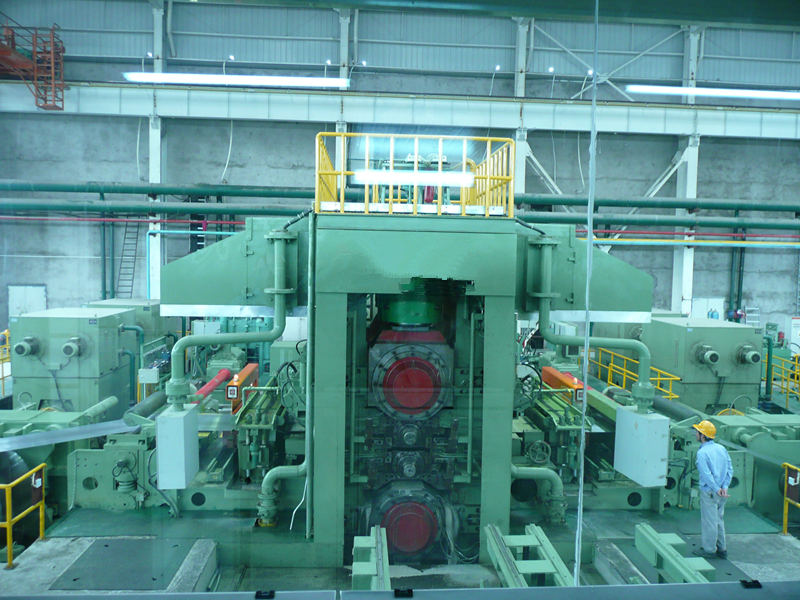

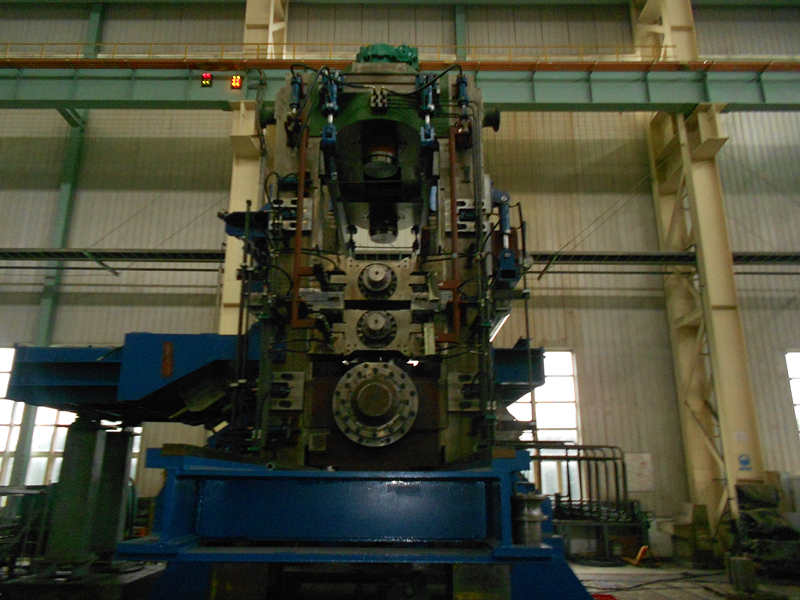

φ160/φ620×800 4-Hi reverse rolling mill(in stock)

- product description

- Technical Parameters

A.conditions

1. material :plain carbon steel

2. steel specification :thickness:2.5mm width700 mm: max coil weight :10000kg

3. product specification:thickness≥0.3 mm width:700 mm volume ID:Ф510 mm

4. rolling force :p≤650 T

5. max rolling speed:v≤180 m / min

6. rolling tension:T≤65 KN

B. main components

1.main machine:φ160 /φ620×800 4 high reverse rolling mill

2. transmission mode : driven by sporting rol

3. screw down device:

a.screw down motor:model power:22KW×2 ,6级 6 level

This motor can either press down and lift at the same time, or press down and lift respectively.

b.high speed level worm gear box:WS250 I=45

center distance A=250mm

c.low speed level worm gear box:twice envelope torus worm .center distance A=480mm

Mn=16mm, I=50

d.press down the screw :S220×8 ,

press down speed:0.05 mm/s

e.the frame adopts steel under pressure

4.rack device :

a. 2 pieces of closed column,column cross profile350×450 ,ZG35

b. the whole processing, artificial shovel blows

c.tension (c) to squeeze the water roller

5.roll system part:

a.working roll diameter×roll surface width:φ160×800

mm,material:9Gr2Mo

bearing :needle bearing 6634916 or bearing bush

c. supporting roll diameter:φ620×760mm ,

material :9Gr2Mo

bearing :FC72104380()dedicated bearing for

rolling mill

c.bearing lubrication way : dry lubrication

d. supporting roll balance way:。Hydraulic

e. changing roll mode :hydraulic pressure to change the roll

6.main transmission part:

a.main motor model:DC motor Z500-4A -723 KW.

554/1200rpm

b.main reducer : ZLY630 series

c.herringbone gear box:

center distance A=920,Mn=14 mm

d.reducer :thin oil lubrication 。

e.transmission shaft type:

the automobile universal joint shaft SWC350×2000.

f.base :two parts motor& reducer & header is one part, rack is another part

7. Coiler:hydraulic recoiling machine

1. recoil diameter :Φ508×800。(with a bracket )

· 2. expansion range :20 mm

3.Hydraulic pushing material, hydraulic trolley car, hydraulic expansion

4.max coil weight :≤10000 kg

5.recoiling tension :T≤6500 Kg

6.main motor :Z4-355-32-355KW 600/1600rpm

7.reducer:ZQ1000型(self-control)

8、thin oil lubrication:

responsible for reducer’s lubrication system。

9、procession lubrication (supplied by buyer)

10、

hydraulic unit uses a hydraulic station control

Has many function, including accumulators, electric contact pressure gauge, unloading device, relief valve, filter device, liquid level display and grade of system pressure control.

11.Thickness gauge: 2 sets, by gamma radiation

12、electronic control system:

12.1、

Electric control electric control system adopts Siemens company. Relay control system adopts PLC programmable controller, machine set up by the organic operation box, with current, speed, tension, such as the thickness of the display

12.2

the main motor, important electrical equipment and machinery safe protection measures, etc.

13、wearing parts information:

1.will provide wearing parts drawing。

2.will provide machine specification and electronic control system drawing 。

14、installation supervision and test:

1、。

The supplier provide equipment installation foundation drawing 2 months in advance to secondary pouring

2、

Equipment to the scene, the supplier is responsible for guiding installation and debugging

Customer is to pay air ticket, hotel, meal, and USD 80/person/day.

15.others: The buyer is responsible for the scope of

Equipment external pipe and cable wiring

about design and construction for machine

Install the required various plate and various specifications of the cable

All kinds of hydraulic station, thin oil terminal line pipe and pipe joints

installation of machine& hydraulic& electronic system;supply will provide technical to give guidance.

Provide required for debugging the hydraulic oil, emulsion, steel belt, gear oil, lubricating oil, grease, etc.:provide the AC driver

If you want to quote or further information on this product, please fill out the form below.

Previous:Used 1450 6-hi reverse CRM

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 12-hi 1100 x 2.0-3.0 reverse CRM

Used 12-hi 1100 x 2.0-3.0 reverse CRM

-

Used 1150 6-hi reverse cold rolling mill

Used 1150 6-hi reverse cold rolling mill

-

used 750 4-hi reverse AGC cold rolling mill

used 750 4-hi reverse AGC cold rolling mill

-

Used 4-hi 3-tandem AGC CRM

-

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

Used Φ280-Φ680 x 1350mm 4-hi aluminum CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

used 1400 12-hi reverse cold rolling mill

used 1400 12-hi reverse cold rolling mill

-

Used Ф190/Ф900×1180 stainless steel 4-hi AGC reverse cold rolling mill

-

Used 1450 four high reversible cold rolling unit

Used 1450 four high reversible cold rolling unit

-

Used 1250 6-hi reverse cold rolling mill

Used 1250 6-hi reverse cold rolling mill

-

Used 650 stainless steel cold rolling mill

Used 650 stainless steel cold rolling mill

-

used 750 4-hi reverse CRM

used 750 4-hi reverse CRM

-

Used 1450 18-hi CRM

Used 1450 18-hi CRM

-

1250mm 6 Hi reversible cold rolling mill

1250mm 6 Hi reversible cold rolling mill

-

Used 1380mm 6-hi reverse cold rolling mill

Used 1380mm 6-hi reverse cold rolling mill

-

460 4-hi 4-stand CRM(new machine in stock)

460 4-hi 4-stand CRM(new machine in stock)

-

6Hi reversible cold rolling mill

6Hi reversible cold rolling mill

-

Used Hitachi 6-hi cold rolling mill

Used Hitachi 6-hi cold rolling mill

-

Used 1250 4-hi reverse cold rolling mill

Used 1250 4-hi reverse cold rolling mill

-

Used roll grinder

Used roll grinder

-

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

Used Ф190/Ф900×1180 4-hi AGC reverse cold rolling mill

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used ⌀180/590 x 700 4-hi cold rolling mill

-

Used 350mm 4-hi reverse cold rolling mill

Used 350mm 4-hi reverse cold rolling mill

-

Used 4-hi 1450 cold rolling and leveling mill

Used 4-hi 1450 cold rolling and leveling mill

-

Used (16-40)×2500mm leveling line

Used (16-40)×2500mm leveling line

-

Used 4-hi 850 electrical pressing reverse CRM

Used 4-hi 850 electrical pressing reverse CRM

-

used 1150 6-hi reverse CRM

used 1150 6-hi reverse CRM

-

Used 20-hi cold rolling mill (India Brand)

Used 20-hi cold rolling mill (India Brand)

-

Used 4-hi skin pass

Used 4-hi skin pass

-

Used 1450 6-hi reverse CRM

-

700mm 20-roll rolling mill in stock

700mm 20-roll rolling mill in stock

-

Used 1450 8-hi CRM

Used 1450 8-hi CRM

-

Used 1450 6-hi reverse CRM

Used 1450 6-hi reverse CRM

-

Used 4 hi skin pass

Used 4 hi skin pass

-

used 800 AGC pressing 8-hi CRM

used 800 AGC pressing 8-hi CRM

-

Used 1150 6-hi reverse CRM

Used 1150 6-hi reverse CRM

-

Used Tippins 1725mm 4-hi reverse CRM

Used Tippins 1725mm 4-hi reverse CRM

-

Used stainless steel 550 4-hi reverse cold rolling mill

Used stainless steel 550 4-hi reverse cold rolling mill

-

Used Ф960*1850 aluminum alloy cold rolling mill

Used Ф960*1850 aluminum alloy cold rolling mill

-

Used 1050 20-hi reverse CRM (AGC)

Used 1050 20-hi reverse CRM (AGC)

-

Used 750 4-hi reverse CRM

Used 750 4-hi reverse CRM

-

used 450 4-hi 3-tandem CRM

used 450 4-hi 3-tandem CRM

-

1500mm Stretching and Straightening Machine

1500mm Stretching and Straightening Machine

-

Used 20-hi cold rolling mill(Japanese brand)

Used 20-hi cold rolling mill(Japanese brand)

-

Used 1250 6-hi reverse CRM

Used 1250 6-hi reverse CRM

-

New 1450 skin pass in stock