Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

Cold Rolling Mill

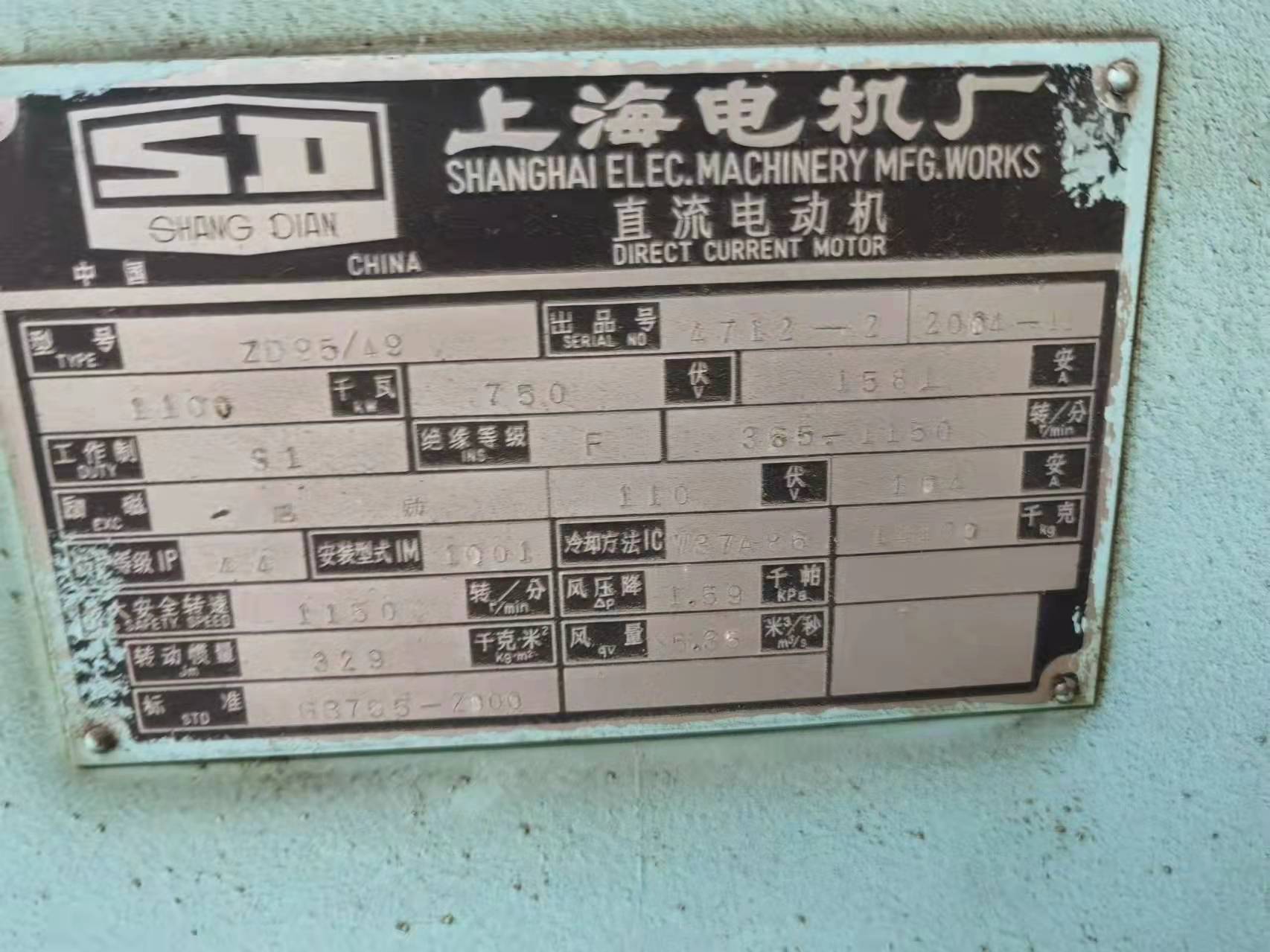

Used 1250 6hi reverse cold rolling mill in Shanghai, China

Product NO.657 written on Feb 12, 2026- product description

- Technical Parameters

Main Technical Parameters

1. Product Process Technical Parameters

1) Raw Material State: Hot-rolled steel coils that have been pickled and trimmed.

2) Raw Material Material: Ordinary carbon steel, high-quality carbon steel, low-alloy high-quality steel, silicon steel (SI ≤ 2.5%)

Representing steel grades: CQ, DQ, DDQ,

Non-oriented silicon steel grade: Medium grade 50W470 ~ 50W600

Low grade 50W700 ~ 50W1300;

3) Thickness: 2.0~3.0 mm (silicon steel)

2.0~5.5 mm (low carbon steel)

4) Width: 900~1300 mm

5) Coil ID: φ610 mm

6) Coil OD: φ1000~φ2100 mm

7) Max coil weight: 25 t

8) Unit coil weight: Max 22.4 Kg/mm

Average roll weight: Max18Kg/mm

10) Steel coil tower shape: ≤40mm

11) Strip steel convexity: ≤80μm

12) Strip steel cross-section wedge shape: ≤50μm

13) Strip steel surface protrusion points: ≤12μm

14) Scimitar bend: ≤5mm/2000mm

15) Width tolerance: Nominal width 0~+10 mm

2. Finished product requirements:

1) Thickness: 0.35~0.85 (silicon steel)

0.2~4.5 (low carbon steel)

2) Width:900~1300 mm

3) Roll ID: 610 mm Æ

4) Roll OD: φ1000~φ2100 mm

5) Max roll weight: 25 t

6) Finished product accuracy: Finished product thickness ±3%

3. Main equipment technical parameters of the unit

Unit name | 1450mm six-roll UCM reversible cold rolling mill |

Max rolling pressure | 20000 KN |

Max rolling torque | 155 KN.m, 175 KN.m (motor overload 115%) |

Max rolling speed | 1000 m/min |

Stripping speed | 30 m/min |

Max unwinding speed | 400 m/min |

Max rewinding speed | 1050 m/min |

Unwinding tension | 8-80 KN |

Winding Tension | 8-230 KN |

High Speed Gear: 8-130 KN | |

Low Speed Gear: 23-230 KN | |

Working Roller Size | Φ385/φ340×1450mm |

Intermediate Roller Size | Φ440/φ390×1480mm |

Support Roller Size | Φ1200/φ1050×1450mm |

Rewinder roll diameter (expansion/contraction) and length | Φ630/φ570×1450mm (Nominal 610mm) |

Reel diameter (expansion/contraction) and length | Φ610/φ587×1450mm |

Frame column cross-section dimensions | 760 × 620 mm, 471200mm² |

Minimum opening degree | 20 mm |

Working roller positive/negative bending roller force (single roller single side) | 360/-180 KN (Max) |

Intermediate roller positive bending roller force (single roller single side) | 450 KN (Max) |

Middle roller lateral displacement | 325 mm(Max) |

Low-pressure hydraulic transmission system pressure | 14 MPa |

Balance bending roller hydraulic system pressure | 25 MPa |

Servo pressing hydraulic system pressure | 25 MPa |

Max acceleration and deceleration speed of the unit | 60 m/min/sec |

Downtime of the unit (from 1000m/min to 0m/min) | |

Normal Parking | 25 seconds |

Quick Parking | 15 seconds |

Emergency Parking | 10 seconds |

If you want to quote or further information on this product, please fill out the form below.

Previous:暂无上一篇

Next:Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

-

2011 used 1700mm cold rolling mill aluminum

2011 used 1700mm cold rolling mill aluminum

-

1250mm 6hi revisible cold rolling mill

1250mm 6hi revisible cold rolling mill

-

CR No.134 Used 1300mm 6Hi Cold rolling mill

CR No.134 Used 1300mm 6Hi Cold rolling mill

-

X No.157 Used X-ray thickness gauge

X No.157 Used X-ray thickness gauge

-

KOBELCO used cold rolling mill 1300mm Aluminum

KOBELCO used cold rolling mill 1300mm Aluminum

-

used 1250 4HI irreversible cold rolling mill aluminum

used 1250 4HI irreversible cold rolling mill aluminum

-

used 1250mm 4 Hi reverse cold rolling mill

used 1250mm 4 Hi reverse cold rolling mill

-

cold rolling mill working rolls

cold rolling mill working rolls

-

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

CR No.114 New 1250mm 6Hi reversible Cold rolling mill

-

used Kobelco cold rolling mill aluminum 1300mm

used Kobelco cold rolling mill aluminum 1300mm

-

No.188 New 1150mm cold rolling mill

No.188 New 1150mm cold rolling mill

-

used 2 stands 1300mm 6hi cold rolling mill

used 2 stands 1300mm 6hi cold rolling mill

-

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

1992 CFHI 1050mm 4hi irreserve CRM Aluminum Foil

-

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

2007 China 1st Heavy Machinery 1300mm 6 hi reverse CRM

-

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

Used 1450mm 20hi Cold rolling mill in Shanghai (I²S TENOVA), China

-

used tension leveler aluminum

used tension leveler aluminum

-

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

1966 LOEWY ROBERTSON 1600mm 4hi one stand one directioncold rolling mill aluminum foil

-

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

1974 LOEWY ROBERTSON 1600mm 4hi one stand one direction cold rolling mill aluminum foil

-

used 1250mm 6hi cold rolling mill

used 1250mm 6hi cold rolling mill

-

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

used 1250 4Hi irreversible foil No:2 Cold rolling mill aluminum

-

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum

used 1250mm 4Hi irreversible foil No:1 Cold rolling mill aluminum