Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

Electric Tower Production Line

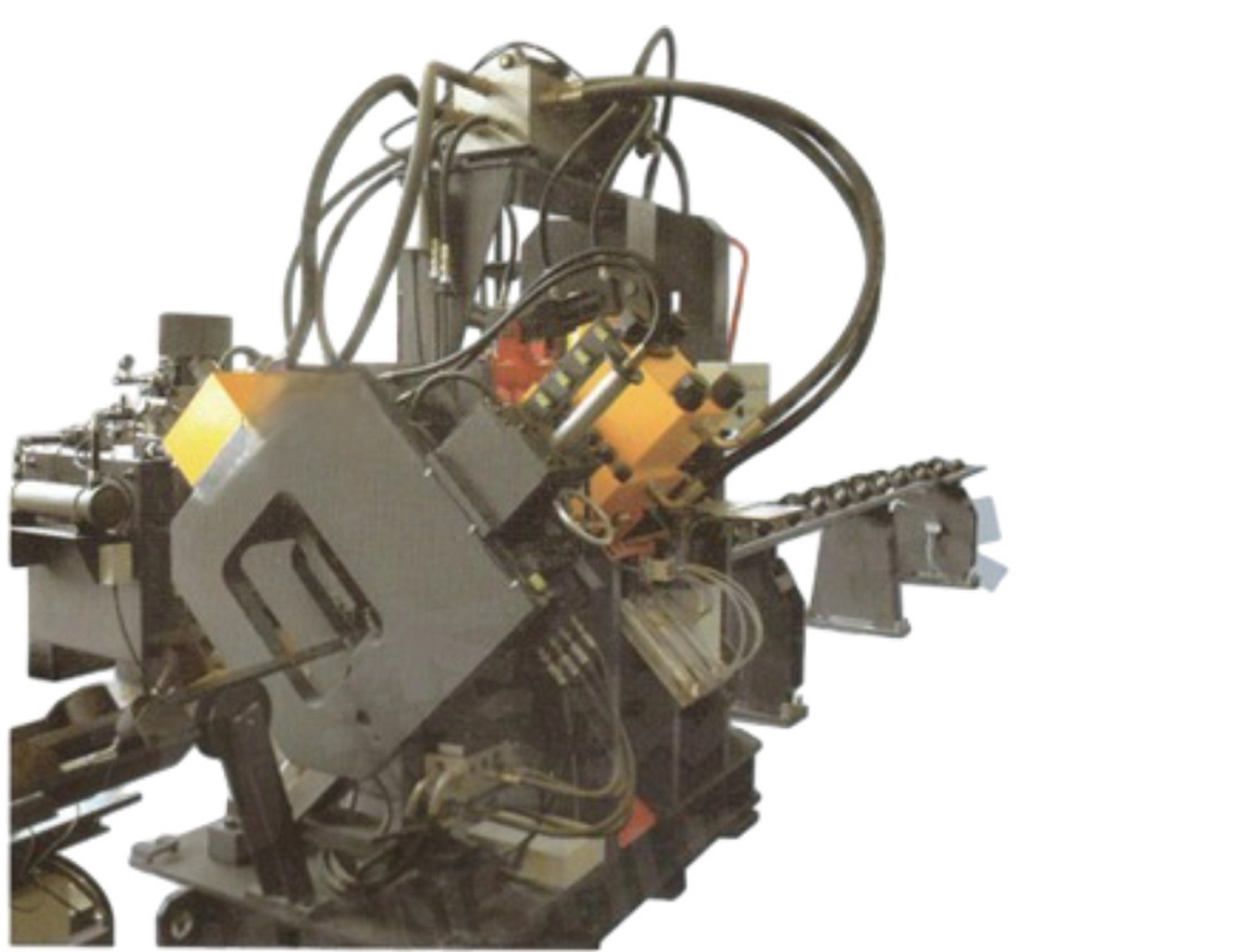

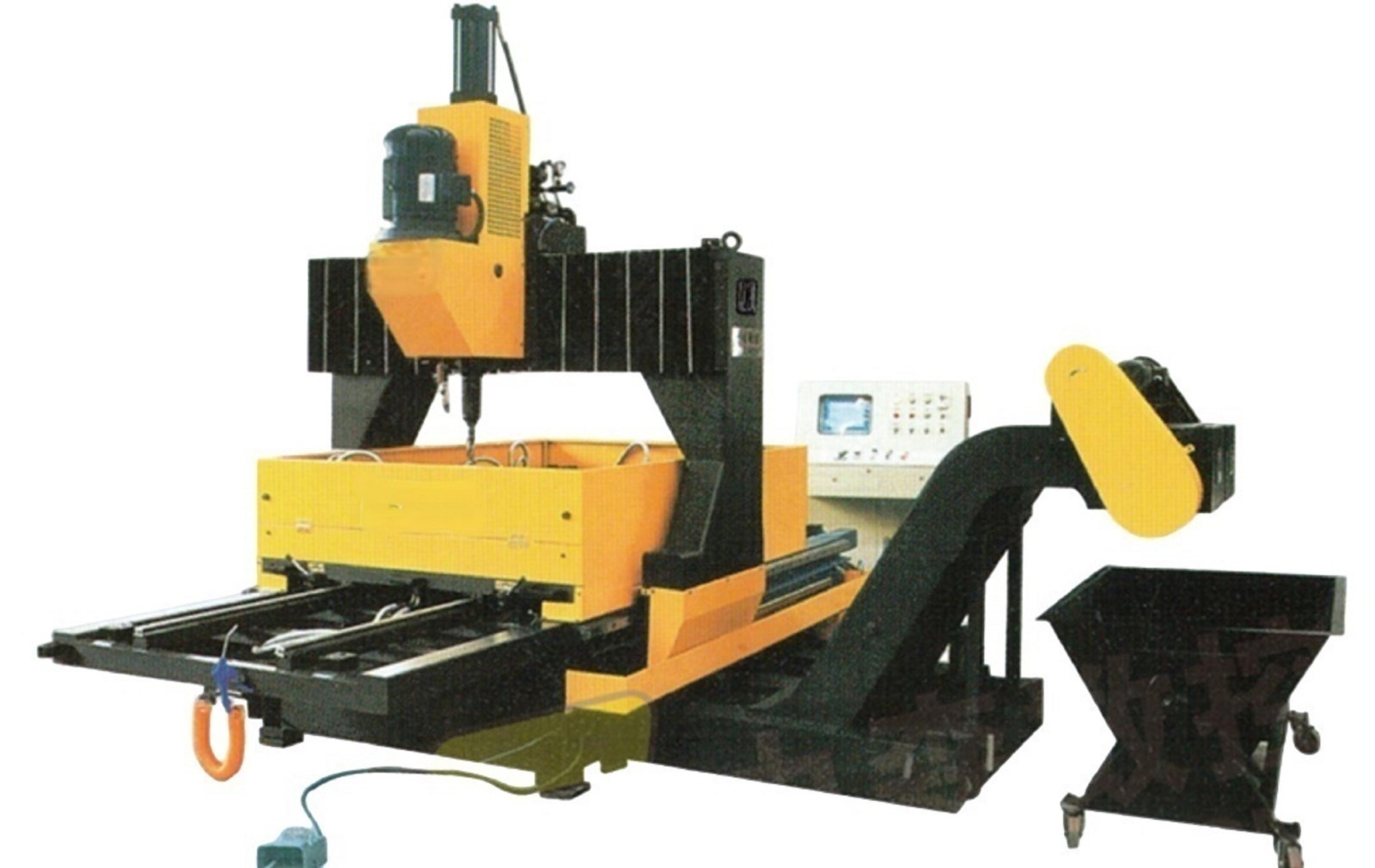

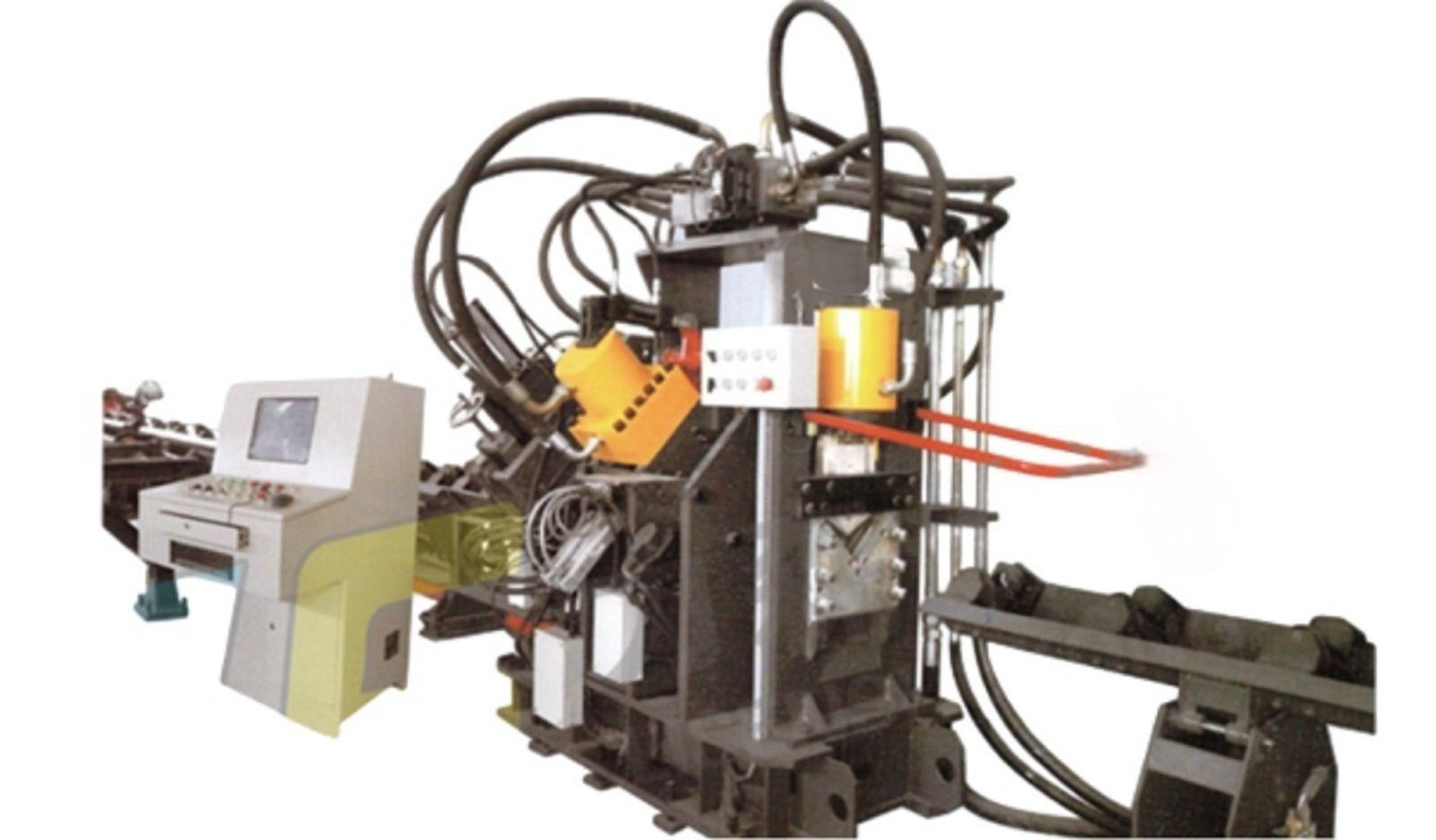

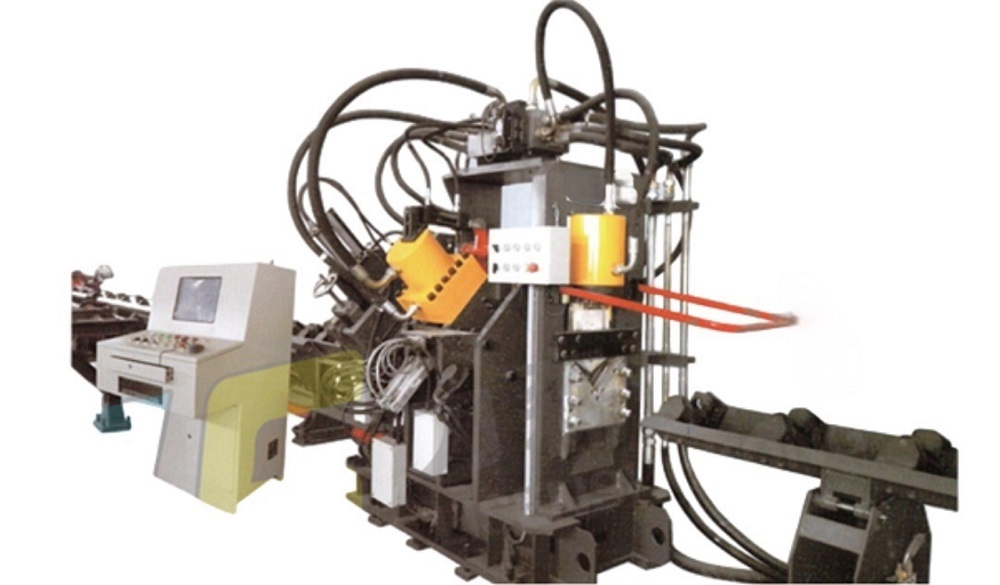

1214-CNC Angle Steel Production Machine

stock number: 626, it is written on June 5th,2025- product description

- Technical Parameters

LSBL1412A/LSAPM1412(enhanced)/LSAPM1412-3(enhanced)

CNC angle steel production line

Product Industry:

This machine is mainly used for fully automated production of angle steel typing (stamping), punching and shearing.

It is widely used in power angle steel towers, communication angle steel towers, power fittings, storage shelves, steel structure buildings and other industries.

Features:

The advanced supporting device has obtained the national patent certificate and improves the processing accuracy of angle steel.

TBL1412A has two sets of punching dies on the two wings of the angle steel, while TAPM1412 and TAPM1412-3 have three sets.

All holes on the angle steel can be processed at one time.

Single-blade shearing saves raw materials and produces neat cut surfaces.

The machining process is numerically controlled and the operation is very convenient, which can realize automated, high-precision, multi-variety and large-scale production.

The typing unit adopts a closed body with good rigidity.

The typewriter is equipped with four sets of programmable typehead boxes, and the typing distance can be set at will.

The CNC feeding trolley is driven by a servo motor with high positioning accuracy.

The hydraulic system mainly completes punching, cutting, stamping, pressing and letter box replacement.

The control system consists of a host computer, servo motor, PLC, external detection sensors, etc.

The workpiece program supports manual programming and can also accept workpiece processing programs generated by the layout software.

The key liquid, gas and electrical components are all from well-known domestic and foreign brands.

It has the function of free cutting and can process fixed-length materials.

With fault self-diagnosis function.

Technical Parameters:

LSBL1412A | LSAPM1412 | LSAPM1412-3 | |

Processing angle steel range (mm) | 40×40×3~140×140×12 | 40×40×3~140×140×12 | 40×40×3~140×140×12 |

Maximum punching (mm) | Φ26×12 | $26×12 (Q420) | Round hole $26×10 Long hole 22x50mm |

Punching nominal force (kN) | 600 | 1000 | 1000 |

Typing power (kN) | 630 | 1030 | 630 |

Cutting force (kN) | 1800 | 1800 | 1800 |

Maximum length of blank (m) | 12 | 12 | 12 |

Maximum length of finished product (m) | 8 | 8 | 8 |

Number of punches per side | 2 | 3 | 3 |

NO of print prefixes groups | 4 | 4 | 4 |

NO of prefixes in each group | |||

Initial size (mm) | 14x10x19 | ||

Number of CNC axes | 3 | ||

Cut-off method | Single-blade cutting | ||

Angle steel feeding speed (m/min) | 80 | ||

Programmatically | Lofting software or manual programming | ||

Overall dimensions (m) | Approx. 25.4×7×3 | Approx. 26×7×3 | Approx. 26×7×3 |

Machine Net Weight(Kg) | Approximately 14,500 | Approximately 14,800 | Approximately 14,500 |

If you want to quote or further information on this product, please fill out the form below.