Recommended News

contact us

Tel: +86-21-56031255

Mobile: +86-18930968947

E-mail:fcj@muhong.cn

muhongjidian@vip.163.com

wechat: +86-18930968947

whatsapp: +86-18930968947

skype: muhongjoseph

Electric Tower Production Line

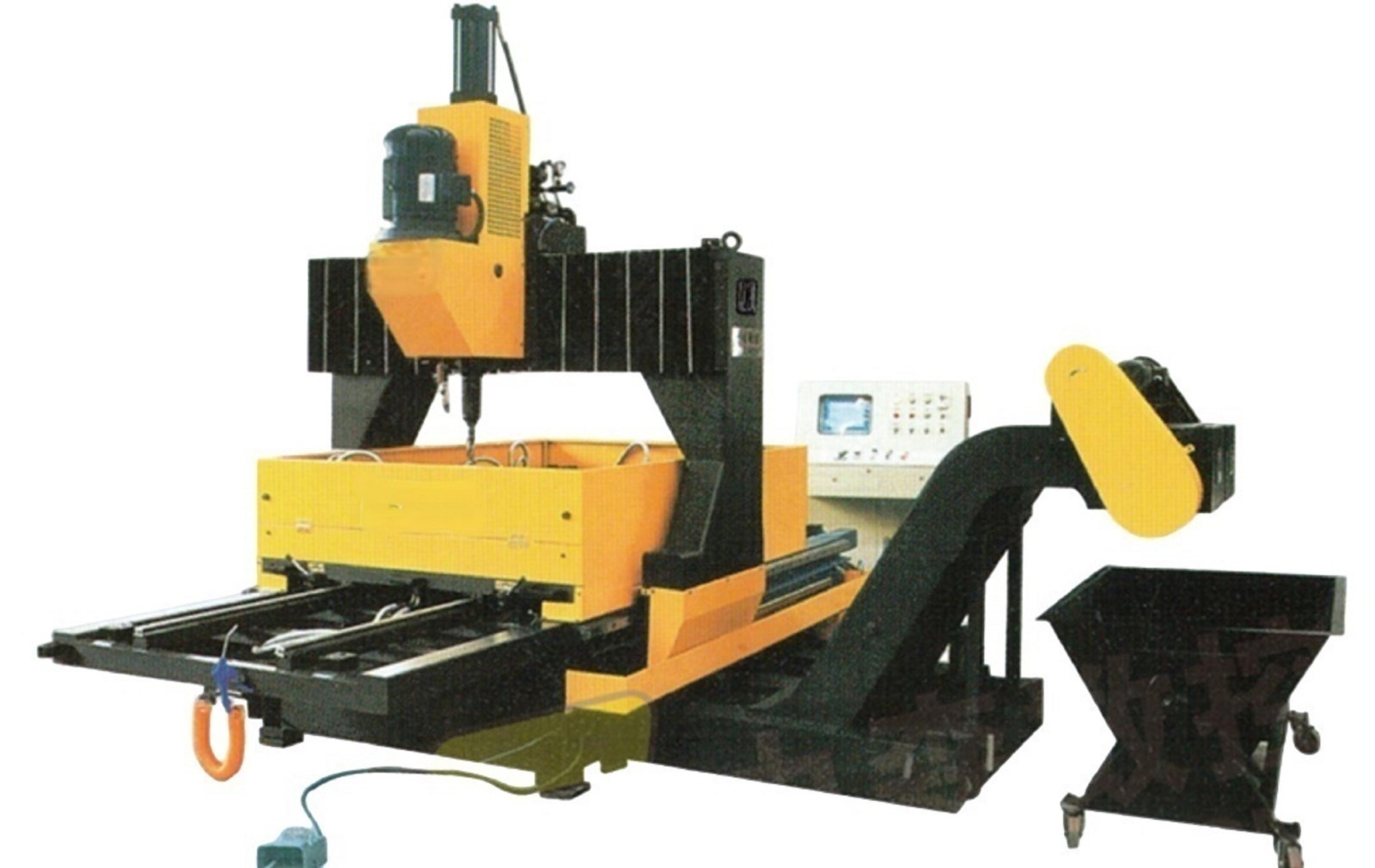

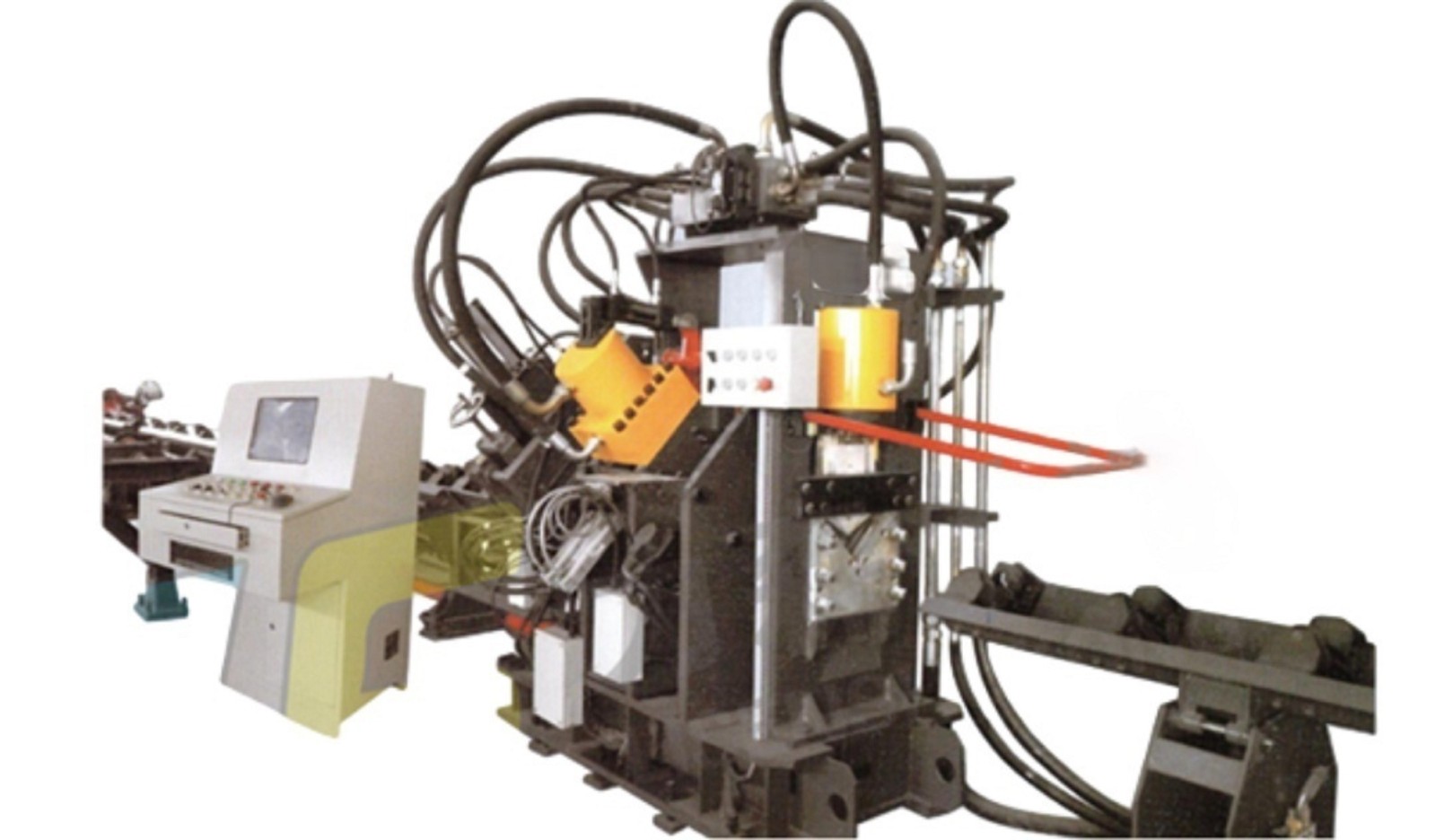

1010-CNC Angle Steel Punching Machine

stock number: 625, it is written on May 11th,2025- product description

- Technical Parameters

Product industry

This machine is mainly used for fully automated production of angle steel typing (stamping), punching (long holes, round holes), and shearing.

It is widely used in power angle steel towers, communication angle steel towers, power fittings, storage shelves, steel structure buildings and other industries.

Features

The feeding and punching speeds are the fastest in China, which greatly improves production efficiency.

The output of 50×50×4mm angle steel is 9-10 tons every eight hours.

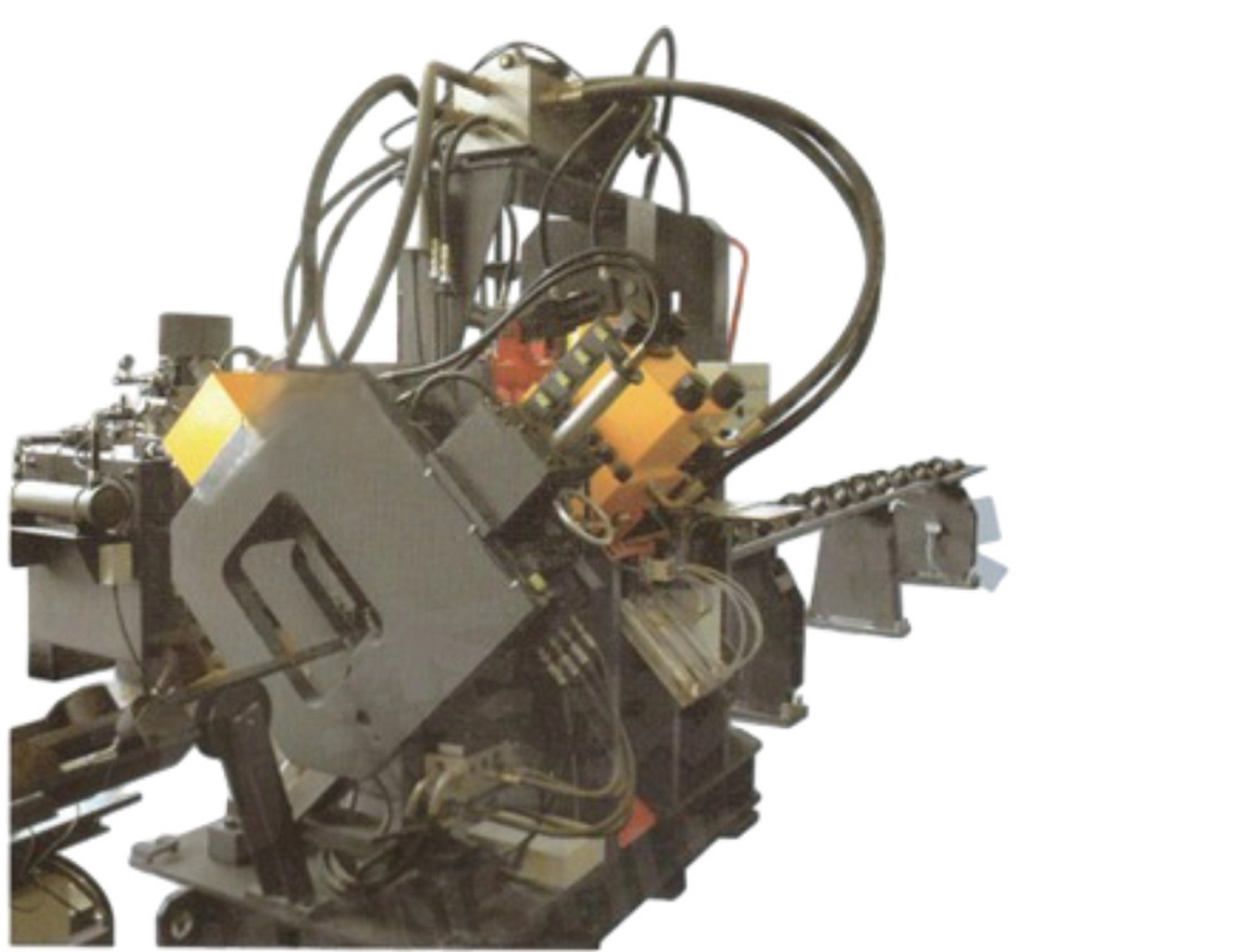

The pressing device, CNC feeding trolley, supporting device, trolley clamp claw, etc.

have all obtained national patent technology protection and adopted the most advanced technology.

It adopts PLC module control and servo motor feeding, with high efficiency and stable processing accuracy.

The programming is simple and the program data generated by the layout software can be used directly.

The files in NC1 format can be read.

The computer has a Chinese/English interface, is easy to operate, and can display workpiece graphics.

Printing, punching, and cutting are all done automatically; the finished products are unloaded by pneumatic overturning.

Single-blade shearing function saves more raw materials.

The new feeding channel adopts the transmission mode of linear guide + rack, which has high precision.

The linear guide is made of special steel, nitrided, and anti-corrosive, so it is not easy to rust.

The rack is quenched. The hardness and wear resistance of the linear guide and rack are higher than the old normalized rack.

It will not be damaged even after long-term friction, has a long service life, and more stable performance.

The clamp rod buffer device of the CNC feeding trolley is guided by a linear guide rail, which does not vibrate and is more stable. The clamp rod is lifted by a cylinder, which is fast and efficient.

Technical Parameters:

LSAPM1010 | LSAPM1010-2 | LSAPM1010-3 | |

Function | Punching, Typing & Cutting | ||

Processing angle steel range (mm) | 40×40×3~100×100×10 | 40×40×3~100×100×10 | 40×40×3~100×100×10 |

Maximum punching (mm) | Φ26×10 (Q345) | Round hole $26×10 Long hole 22x50mm | |

Punching nominal force (kN) | 600 | 1000 | 1000 |

Typing force(kN) | 630 | 630 | 630 |

Cutting force(kN) | 1200 | 1200 | 1200 |

Maximum length of blank (m) | 10 or 12 | 10 or 12 | 10 or 12 |

Maximum length of finished product (m) | 8 | 8 | 8 |

Number of punches per side | 2 | 2 | 3 |

Print header group number | 4 | 4 | 4 |

Head size (mm) | 14x10x19 | ||

Number of CNC axes | 3 | ||

Cut off method | Single-blade cutting | ||

Angle steel feeding speed (m/min) | 80 | ||

Programmatically | Lofting software or manual programming | ||

Overall dimensions (m) | Approx. 25×6.5×2.5 | Approx. 25×6.5×2.5 | Approx. 25×6.5×2.5 |

Machine Net Weight (Kg) | Approximately 13,000 | Approximately 14,000 | Approximately 14,300 |

If you want to quote or further information on this product, please fill out the form below.

Previous:暂无上一篇